Complete Casting Solution Service for your project

With experienced production team and World-class Casting mold and casting production equipment to ensure your project success, Dedicated person tracks project progress. Casting mold and Casting production 100% meets size and assembly requirements

- Die casting

- Investment casting

- Gravity Casting

Custom Casting mold and Casting production service

Our Custom Casting Part Services

Ace Customs Casting And Casting Production Servie

Ace is one of the top high precision Die casting, Investment casting and Gravity Casting manufacture supplier in China. From Customer idea to actual part. We are able to make various of Casting, such as alloy die casting and Electrophoresis die casting ,Electrophoresis die casting, Electrophoresis die casting, also for Investment casting, Gravity Casting mold manufacture and part production for our overseas customer.

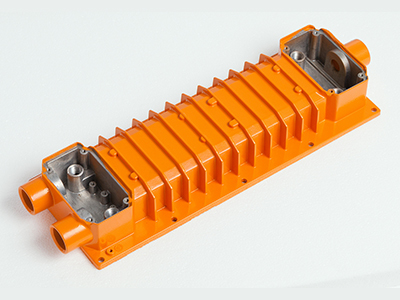

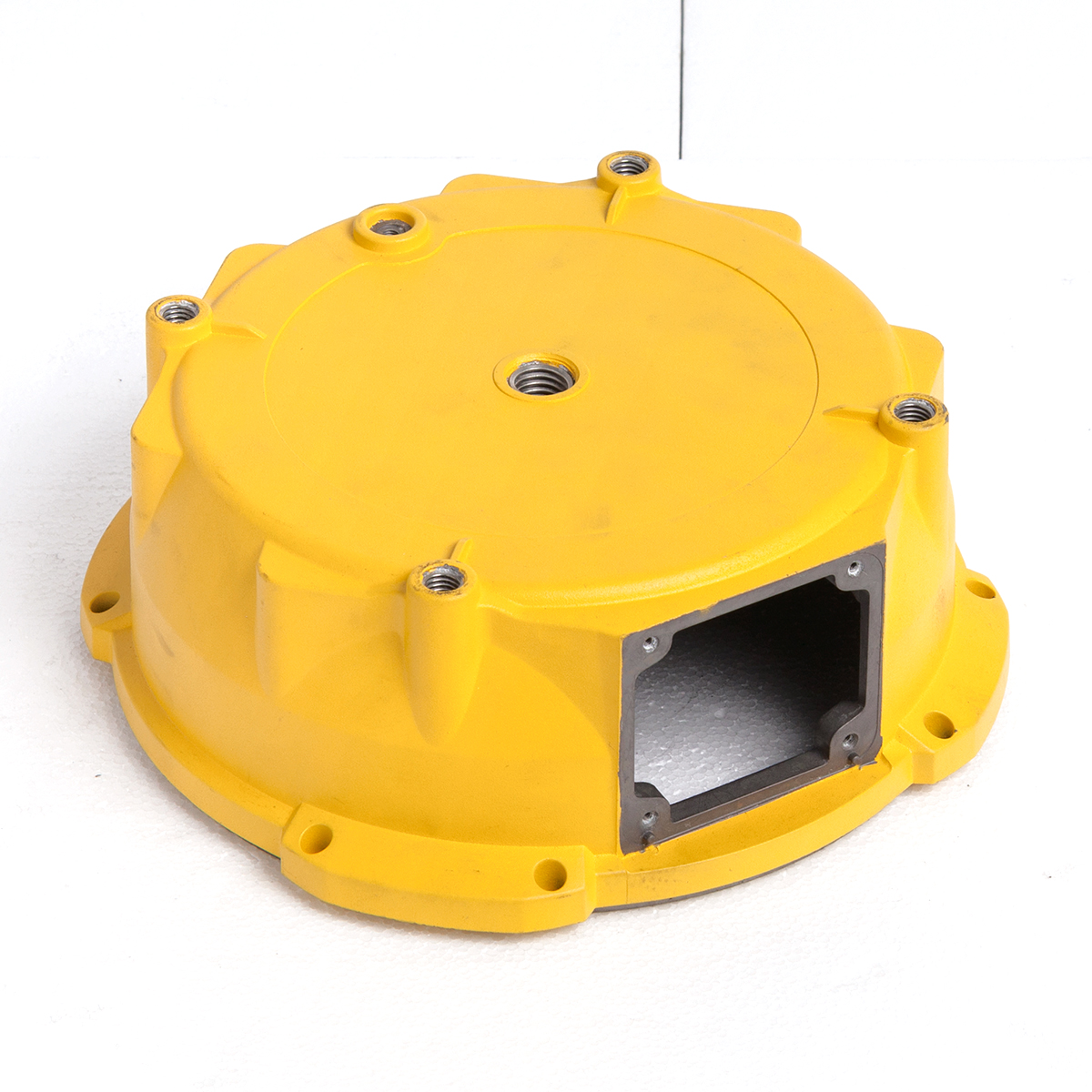

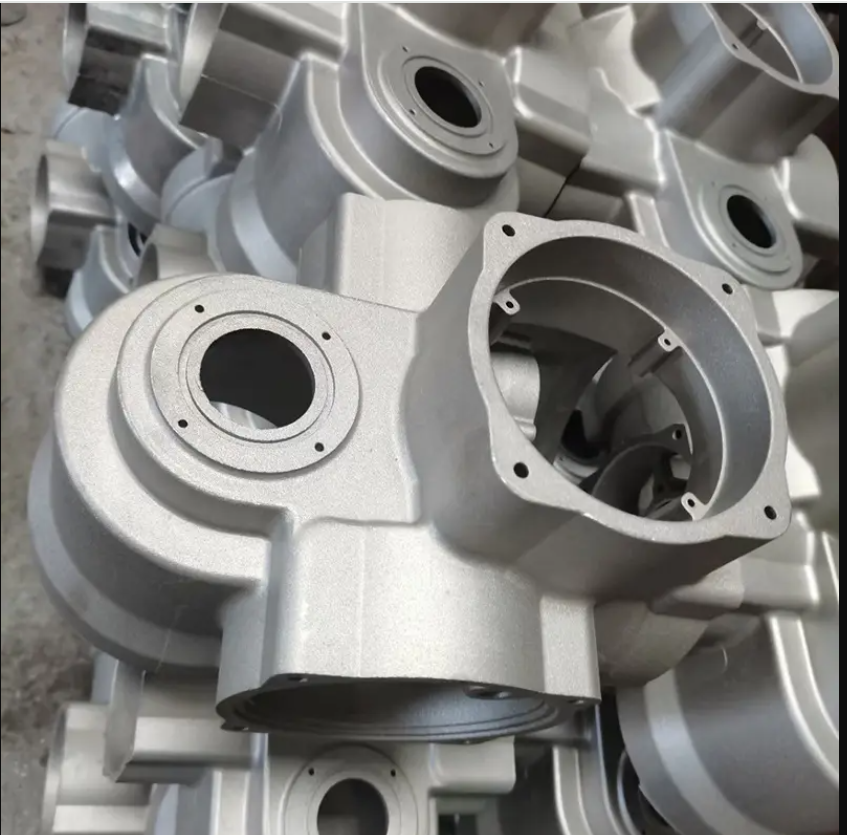

Custom Casting Molded Products by Ace-mold

Explore the Casting prototypes and custom production parts we’ve crafted for our clients, available for on-demand orders.

Casting production Whitepaper

Gaining knowledge about the Casting production process is crucial for designers and engineers to design parts that are manufacturing-friendly, leading to cost reduction and quality enhancement. Our ebook is a valuable resource, offering practical advice and guidelines for creating exceptional and long-lasting Casting production components.

Casting production Process At Ace-mold

Discover how Ace-mold manages your orders, starting from providing quotes, crafting high-quality injection molds, to producing production-grade Casting parts. Our experienced team and advanced machinery ensure each step is completed efficiently for on-time delivery

Request for Quote

After receive the RFQ, our engineering department will have meeting to study the best solution for the quote, we will provide the quotation according to your request, if we can quote, that means we can make the part perfectly, quotation time within 24 hours

DFM Report

We can provide the preliminary during the quotation stage if customer request, after order kick off we will make the details DFM for our customer confirmation.

Mold Flow Analysis

We have our own internal Moldflow team to analysis the part details, we can provide the customer suggestion for part after study the mold flow analysis report.

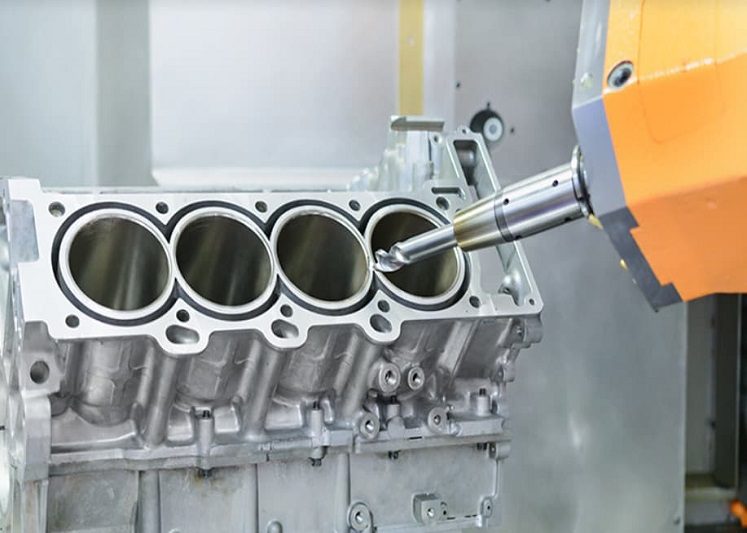

Mold Tooling Production

We will strictly check the components dimension make sure all dimension is correct and we will go ahead with the next production, to make sure all components is in tolerance before mold test

T1 Sample Verification

We will provide the request quantity sample for customer verification, meanwhile we will provide the full dimension report and processing parameter for your reference.

Low Volume Production

Depends on the customer request We have 25 CNC the maximum can make 1.5 meter part to rework on the casting part after production

QC Inspection

We can provide the part CMM and 3D scan service inspection. To strictly follow customer provided tolerance drawing to check the actual part.

Package and delivery

We will provide the different package according to customer transport request, by sea or by air. We will also provide the necessary document to assist our customer make customs clearance.

Our Die casting Solution services cater to a range of industrial applications

Ace-mold tailored complete casting solutions to meet the unique needs of various industries

Automotive Industry

Aerospace Industry

Medical Device Industry

Robotics Industry

Reasons to Opt for Our Specialized Custom Casting Production Services.

No MOQ

Our no minimum order policy facilitates the swift transition of plastic molded parts from design to production with quick turnaround times, catering to your on-demand Casting Production requirements while also minimizing costs.

High Quality and Consistency

Possessing ISO certified factories and performing in-process inspections and dimensional verifications post-production, we ensure consistent quality in custom molded parts. This holds true even for complex shapes, as we maintain high precision throughout

Fast Turnaround

Our certified domestic factories and robust supply chain system enable us to expedite the product development cycle, allowing for the rapid production of casting parts in as little as 2 weeks or even less.

Casting Production

Work alongside our specialists, who have over 20 years of experience in Casting Production, for expert advice on mold design, material selection, and finishing options, ensuring a seamless shift from prototyping to full-scale production.

casting production is a service that involves the manufacturing of Castingparts using a molding process. Here’s an overview of what this service typically includes:

- Design and Engineering: The process usually begins with the design and engineering phase, where the specific requirements of the Casting part are determined. This includes its size, shape, complexity, and the type of Castingmaterial to be used. CAD software is often used to create a precise design.

- Mold Making: Once the design is finalized, a mold is created. The mold is a crucial part of thecasting production process, as it shapes the final Casting product. Molds are typically made from steel or aluminum and are precision-machined to match the design specifications.

- Material Selection: The appropriate Casting material is selected based on the part’s application, durability requirements, and other factors like temperature resistance, strength, and flexibility. Common materials used include ABS, polycarbonate, polyethylene, and nylon.

- casting production Process: In this step, Casting pellets are fed into an injection molding machine where they are melted. The molten Casting is then injected under pressure into the mold. Once the Casting cools and solidifies, it takes the shape of the mold.

- Cooling and Ejection: After injection, the Casting part needs to cool and solidify. Once it’s solid, the part is ejected from the mold. The mold can then be used again for the next cycle.

- Post-processing: After ejection, the parts may undergo various post-processing steps like trimming of excess material, polishing, or painting. These steps depend on the specific requirements of the part.

- Quality Control: Throughout the process, quality control measures are taken to ensure that the parts meet the required specifications. This includes checks for dimensions, material properties, and overall appearance.

- Assembly and Packaging: If required, parts can be assembled with other components. Finally, the parts are packaged and prepared for shipping.