In this article, we are going to discuss shoe moulding which is the process of moulding, what material is used for moulding, and the benefit of using the best mould in the market. It is therefore the desire of this agency to ensure that such information is delivered simply and contains technical features and useful data. Let’s dive in!

What is Shoe Molding?

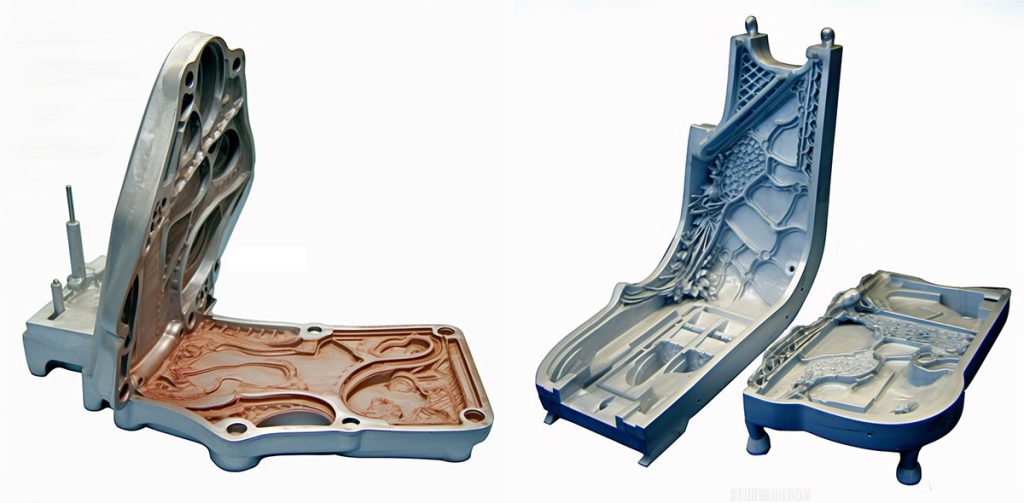

Shoe moulding entails the making of moulds that define various segments of a shoe. These moulds have become critical when it comes to the manufacture of standard footwear with the right size and good performance. Shoe moulds are used in every step of the process of putting together a shoe, making the shoe sole, shaping the upper part of the shoe as well putting support to the insole.

In its most simple definition from the technical point of view, a shoe mould is a form used to manufacture identical sneakers. It also aids in the confirmation of every pair that is manufactured to have the same design and quality level. The mould provides the required shape to the final product and its reinforcing structure to the material used; this could be rubber or leather. Molds differ depending on the material and kind of shoe that is being produced with each one having its mold.

Shoe Moulding Processes

Depending on the design and the materials used in the production of the shoes different molding processes are used. Let’s look at some of the most common moulding techniques:

Injection Moulding Shoe

Injection moulding is the process where a molten material- rubber or plastic, is injected into a mould. It is also a fast way of producing shoes in large numbers and equal quality. It is common knowledge that it is particularly applied for making soles and other parts of shoes which need extreme accuracy.

Blow Molding Shoe

Hollow shoes as well as air-filled soles are some of the parts that are produced through blow molding. However, in this technique, a plastic tube, which is heated, is blown into a mould that has the form of the shoe part. It is particularly famous for producing light and cushioned midsole.

Die Casting Shoe

Die casting is a manufacturing process that is utilized in moulding metallic pieces in the right shape and size. They can not only be used for forming different kinds of shoe components. This method is preferred where higher accuracy and repeated usage of the mould are desired since it is very sturdy.

Rotational Molding Shoe

Rotational moulding is a slower process but very efficient in the manufacturing of shaped items which has hollow build-up layers and thick walls. This is especially ideal in creating certain aspects of a shoe such as midsoles which need structural support.

3D Printing Shoe

The rise of 3D printing technology is greatly affecting the footwear industry since it provides moulds that can easily be modified and manufactured. This method enables the creation of prototypes and even refinement of the molds within a short period hence ensuring that every mold created meets specific standards.

Advantages That Come with the Use of Quality Shoe Molds

Procuring quality shoe moulds is very important to achieve the set design and functionality features of the final shoes. Here are some of the top benefits:

Consistency in Production

Heel moulds enable one to be certain that every shoe made is a replica of the other and this is plausible in terms of the batches as well. This is essential for large-scale manufacturers for they have to meet the production requirements of a large number of consumers while maintaining quality at the same time.

Improved Comfort

The right mould helps the manufacture of shoes that will fit properly and without causing the user discomfort or causing injury. Proper design of a mould permits the foot to lie flat on the cast reducing pressure on the foot and improving the health of the foot.

Durability

Better quality moulds produce quality shoes, in terms of the quality of the shoe soles produced from those moulds, they are durable. Such are aspects such as an EVA sole that can help in cushioning our feet or a leather mould that creates a perfect fit on our feet to help in satisfying the customer.

Eco-Friendly Options

A few of the shoe moulds are made from environmentally friendly substances and manufacturing techniques. The moulds can be created with little wastage during the production process, and therefore are more eco-friendly options in the marketplace for brands who want to take an environmentally friendly approach.

Basic Factors to Consider When Selecting a Shoe Mold

When selecting a shoe mould, it’s important to consider the following factors:

Material Compatibility

Mould material should also depend on the kind of shoe that you want to manufacture. These moulds are most effective when it comes to lightweight, soft-sold shoes while leather moulds are right for formal Shoes.

Durability

It is vital to use a strong mould if the production is going to be long. Flexibility is inherent in the material used such as TPU and the material is strong enough to accommodate several uses without degradation.

Cost-Effectiveness

One must leverage his or her money by opting for a good mould to avoid spending much money carrying out repairs or even changing moulds. While it is more costly to get your own shoe moulds, the cost must be paid since they enable better shoe moulding and thus improved footwear.

Eco-Friendliness

For those who place sustainability on high priority, it will be pertinent to opt for environment-friendly moulding materials and methods. Decreasing waste during production is not only important to the environment but also paramount for the environmentally sensitive consumer.

Why Shoe Molding Is Important For Shoe Making?

Shoe moulding is a process that cannot simply be defined as technical, but, it forms the foundation of any footwear company that wants to produce high-end products. Comfort, durability, and styles can be a goal when designing a product and the array of appropriate molds can be crucial to making a perfect product possible. The moulds utilized need to be strong and of high quality that is suited for the material being used and the method of production to guarantee long-lasting footwear.

To know more about shoe moulds and their effects on footwear production please our website Ace-Mold.

Conclusion

Shoe moulding is a critical aspect of footwear production, ensuring that each shoe not only looks good but also fits comfortably and performs well. By choosing the right moulding materials and processes, manufacturers can produce footwear that meets the needs of both style-conscious and performance-driven consumers.

For more technical details and solutions tailored to your needs, explore our collection at Ace-Mold. By applying advanced moulding techniques and keeping an eye on eco-friendly solutions, you’ll not only stay ahead of the competition but also contribute to a more sustainable future for footwear production.