An essential part of the process is the mould for resin casting that defines the form, surface and fineness of the resin product. Regardless of whether you are a beginner in resin artwork or a professional, it is crucial to make the right choice regarding the mould to use. Here in this guide, we will discuss the mould for resin casting and everything that you need to know.

What is a Mould for Resin Casting?

A mould for resin casting is then a form or matrix within which a mould is produced to give the shape of the liquid resin while it is still in the process of hardening. Molds also vary in shape and material; there are silicone moulds, and metal moulds among others and they have different uses depending on the type of resin project that one is undertaking. The mold serves as the map and your final resin piece is going to resemble the mold in every single way.

Why Work With ACE Group?

At ACE Group, we show our commitment and dedication to serving all businesses around the globe as their strategic business partner. Here’s why you should choose us for your next project:

Expert In-House Design and Development Team

The dedicated in-house design and development team is highly professionalized and also is familiar with the various project requirements of foreign clients. At this point, it is important to note that we appreciate and address all clients’ peculiarities of the tasks.

OEM/ODM Services with 24/7 Support

To ensure that the client gets the services he or she wants, we offer OEM/ODM services with high levels of customization. We offer round-the-clock customer support and project management which means that you will receive regular updates from us.

Strict Quality Control System

Quality in its broadest sense is central to all of our activities. This assures the quality of every product we deliver since we practice very strong quality assurance. Our main goal is to present to you only high-quality products for an affordable price.

Quick Access to Quality Inspection Samples

We also make available quality inspection samples that can be shipped to you promptly to provide first-hand experience of the quality that should be expected from our company.

Custom Design Capability

Our team will be in a position to work on determining the kind of product that you want and then proceeding to make it in the best way possible which will help make it a perfect fit for you.

On-Time Delivery and Transparent Communication

We work hard to meet the deadline of every order and keep the customer updated regarding the progress all through the process.

We at ACE Group believe in trust, the right approach to a problem and excellent service. Call today to see how we can improve your business prospects!

Moulds Maintenance Tips You Need To Consider

Your resin casting moulds are an investment, and if treated well, you’ll find that you can use the same moulds for a long time. Here are a few tips to extend their lifespan:

• Clean after each use: Cleaning your moulds: Use a soft cloth and warm water mixed with some soap.

• Avoid sharp tools: Cutting tools when used to remove resin are likely to harm or mess up the mould, especially the silicone ones.

• Store properly: Store moulds in a cool dry area to avoid warping due to exposure to heat or sunlight.

Factors to Consider When Choosing a Resin Mold

Size of the Project

Such simple tasks as making resin moulds demand more complex moulds compared to larger projects such as making tabletop decor that needs more hardy moulds for the support of resin weight.

Material Compatibility

Epoxy for instance will require a flexible mold such as silicone while another may require a rigid mold such as polyurethane.

Reusability

When a project involves continuous casting, then it is advisable to use a mould which is long-lasting and can be reused. Molds made of silicone are preferable in this case as they remain rigid and elastic throughout the process and can be used several times.

Mould for Resin Casting: A Key Step in Casting Production

Casting production is one of the most significant services in the manufacturing industry because it deals with the moulding process of casting parts. Of interest is the mould for resin casting which is critically responsible for the overall formation of the product. Here's an overview of the resin-casting production process:

Design and Engineering

It starts from the designing and engineering stage, in which specific characteristic of the casting part is determined. Some of the factors to be considered include the size and shape of the required part, the complexity of the shape, and the sort of metal that is to be cast. Such specialized knowledge is often applied with the help of more advanced CAD tools which allow one to make an accurate drawing before moving to the next stage.

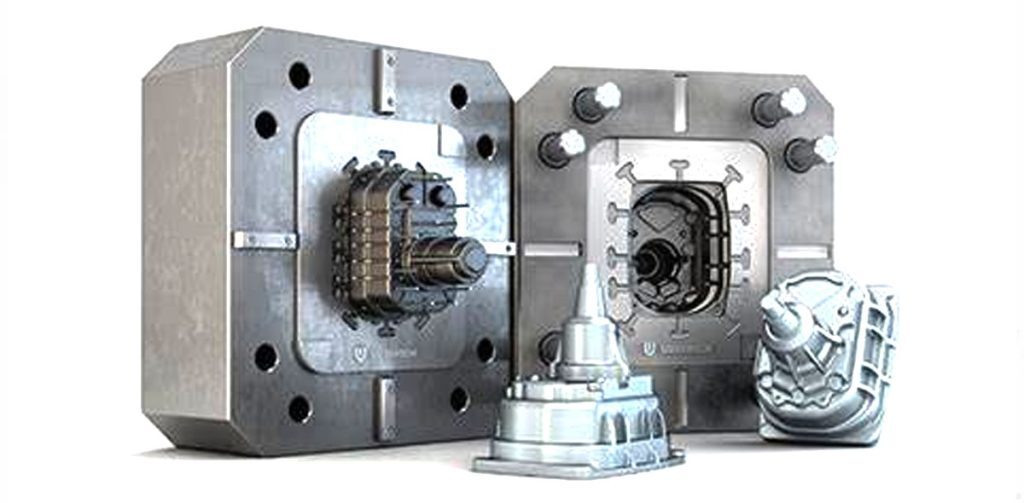

Mould Making

Subsequently, depending on the agreed-upon design, the mould for resin casting is produced. This mould is critical since it defines the final shape of the product to be produced. Generally, moulds are created using strong and hard materials such as aluminium or steel to enable high levels of accuracy in the production line.

Material Selection

The material that is to be used for making the casting is chosen concerning the requirement of the part that has to be cast and properties like strength, flexibility heat resistance etc. Some of the most used materials used are; ABS, polyethylene, polycarbonate, and nylon depending on the industry's applicable uses.

Casting Production Process

The ‘actual casting production’, therefore, starts with casting pellets being fed into an injection moulding machine. After some time, these pellets are first melted and then putting pressure, they are injected into the mold. The molten material goes into the mould and assumes the shape of the latter while it is cooling and later on turns solid.

Cooling and Ejection

Finally, the ‘flash’ occurs; it is the thin layer of material that forms along the parting line, and the C-Part cools and solidifies inside the mould. Once the material has been fully cured the part is then ejected out and the mold can be reused for subsequent cycles.

Post-processing

Other operations that can be classified under post-production may include shaving sanding or perhaps painting the part. These processes help to determine the degree of processing of the product according to the customer’s requirements.

Quality Control

In every step, there are checks and balances that are applied to guarantee the accuracy of the casting parts as per the set dimension and quality of material as well as surface finish requirements.

Assembly and Packaging

Also, the last step, if necessary, parts are joined with other parts and or other components-packaged and shipped as done in the resin casting production.

Conclusion:

Finding the right mould for resin casting is key to mastering the art of resin crafting. Remember to choose a mould that matches the scale, material, and intricacy of your project. Most importantly, have fun experimenting with different mould types and resin casting techniques! For more information on resin casting supplies and advanced techniques, visit Ace-Mold.