Precision Injection Molders: A Definitive Guide to High-Grade Injection Molding Services

The world of manufacturing today requires the effective production of accurate and high-quality plastic components. Manufacturers from numerous industries require high-quality accurate and dependable precision injection molders for manufacturing complex and high-performance parts. In this article, you will be informed on the following aspects: what precision injection molding is how it actually operates, and why industries using quality plastic parts should consider it.

What is the Meaning of Precision Injection Molding?

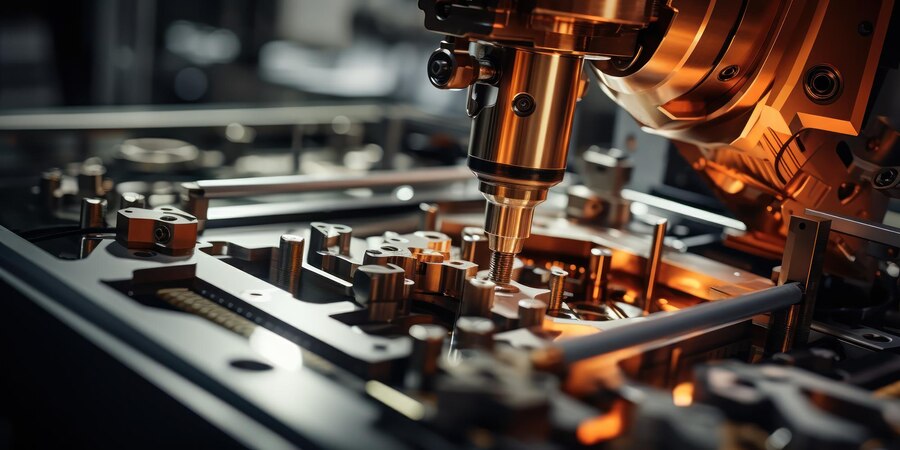

Precision injection molding is a highly technical method of manufacturing complex shape plastics with specific tolerance requirements. In comparison with conventional injection molding, it should be noted that precision molding is characterized by appropriate strict control of deviations in the dimensional accuracy of the detail. In fact, this method finds great application in the manufacture of components that call for precision, fine finish, and regularity.

This employs forcing the molten plastic through a steel or aluminum mold, which gives the plastic its particular form when it in turn cools and solidifies. Precision injection molds act as an immaculate form, where all the structures employed in relation to precision injection molding are fashioned to make certain that the produced product becomes precise in meeting the standard desired.

The Importance of Precision in Injection Molding

Whenever an injection mold is produced, the quality of the end product part depends on the accuracy of the molding process. Here's why precision is crucial in this field:

Tight Tolerance Control: High-accuracy injection molders are able to produce accurate injection molding where the rate of change of size of the formed part is negligible. This is especially so in fields like medical device injection molding, where a slight deviation could mean a product failure or some level of safety issues.

Dimensional Accuracy: Dimensional stability achieved guarantees that all the various components form perfect fits during the assembly stage. This is well illustrated in industries such as electronics injection molding where the parts need to fit into a system without short-circuiting it.

Enhanced Part Quality: High-precision injection molding allows for less imperfections and requires less post-production adjustments to make the desired product. This makes it faster and hence economical, it is therefore considered as one of the most efficient injection molding for industries with high turnover rates.

Benefits of Working with Precision Injection Molders

Selecting the right precision injection molders offers companies with certain benefits as will be discussed below. Here’s a breakdown of the core benefits:

Cost-Effective Manufacturing: The markets provided by precision molding are affordable with less demand over expensive manual labor and less wastage due to efficient injection molding. Reducing time to market, and avoiding the production of defective parts are other factors due to which adopting the right technologies means cutting down long-term expenses.

Fast Turnaround Times: Since most of precision injection molding companies are capable of performing rapid prototyping and low-volume manufacturing, they can provide the prototypes soon. This also favor our businesses in that they can easily carry out experimentation, prototyping, and concept development, and generally get their products to market more quickly.

Consistency and Reliability: Live or interact with a precision injection molder with several years of experience working on different jobs, and you will never have to worry about the quality of your products being compromised. Innocuous injection molding companies are keen on standard procedures to guarantee every part is made to the standard.

End-to-End Manufacturing: Most precision injection molders supply our comprehensive manufacturing solutions; that is, they are able to perform the complete requirement, from product concept right through to the final stage of production. This makes it easier for the supply process and quality check to be done and improved throughout the process.

Industry-Specific Expertise: Various industries require diverse rigidness, durability, and thickness, and sometimes precision molders focus on offering medical injection molding services, automotive injection molding services, or even aerospace injection molding services. The above specialization aids the company in creating and manufacturing parts with consideration to competitive standards.

ACE Precision Injection Molders: Reliable and Precision Plastic Molds

Welcome to ACE precision injection molding expert of highly accurate molds at competitive rates with excellent services. AIM plants itself as one of the most superior precision injection molders with the ultimate intention to provide our clientele with the most compliant lead times and competitive rates for the finest molds and molding services.

Complete Services in Injection Molding

Our catalog contains simple to complex molds including, family mold and over-mold applications. Need small or large injection molded components, ACE can provide you with either one-off penetrations or very large production runs. Our team of experienced employees and technicians provides highly accurate, on-time plastic parts suited to your exact requirements.

Why ACE Precision Injection Molders?

At ACE, we are involved in a partnership with our clients in order to champion their success. That’s why when you share your goals, objectives, and challenges with us we become part of your team, with the singular aim of assisting you achieve those goals. Over the years, we have specialized in providing total plastic solutions in fabrications of mold and molding manufacturing factories with main functional production in cost-effective injection molding.

We at Extreme Mold believe that whenever our clients succeed, we also succeed, this is why we provide reliable and efficient molding services. At ACE, we guarantee that any need you may have will be met through dimensional accuracy, tight tolerances, and quality. The purpose for which you will find us here is to let us assist and assist your establishment to stand out all over the competitors.

To learn more about our services or request a quote, please, contact ACE Mold – the company specializes in precision injection molding.

How to Decide Which Precision Injection Molder is Right for You?

When selecting a precision injection molders, it's essential to consider the following:

Industry Expertise: Ensure that the molder that you hire has dealt with your kind of business before. For instance, if you are sourcing the parts from a company dealing in the medical sector see to it they have a record in medical device injection molding.

Technological Capabilities: High-quality precision molders apply innovative technologies in high-precision injection molding or over-molding in order to correspond to the specific demand.

Quality Certifications: There is also a requirement as to whether the company’s accreditation is ISO sanctioned or not. Certification makes certain that they stick to a very strict policy in quality control.

Customer Support and Communication: Customer service as a tool is as important and must be reliable. Select a company that is open to sharing information from the development of models up to the production of products.

Conclusion

Precision injection molding is an indispensable process for producing high-quality plastic parts with tight tolerances and exceptional accuracy. By partnering with precision injection molders, companies can ensure that their parts are of the highest quality, whether for automotive, medical, electronics, or aerospace applications. For more information about precision injection molding services, visit ACE, a leader in providing custom injection molding solutions to industries worldwide.