Precision Mold and Die Suppliers: Advanced Manufacturing Experiences

Highly competitive manufacturing today depends heavily on precision mold and die suppliers to deliver top-quality products throughout multiple sector industries. Production processes become dramatically more efficient when manufacturers work with specialized suppliers who excel at precision tooling requirements. This article guide provides essential knowledge about precision mold and dies suppliers by explaining their industrial value and production methodologies and it shows why supplier selection matters for business success.

What are Precision Mold and Die Suppliers?

Precisely made molds and dies along with tooling solutions form the core business of precision tooling suppliers who conduct operations for manufacturing processes such as metal stamping and injection molding among others. By providing superior precision components suppliers play a fundamental role in delivering exceptional quality components at consistent levels. Mold and die, suppliers, specialize in creating exact-match metal parts for medical devices alongside complex plastic pieces needed by automotive production. The services enable companies to maintain exact production operations with economic output at high utilization rates.

Advanced Manufacturing Technologies Used by Precision Mold and Die Suppliers

The production requirements from modern industries force precision mold and die manufacturers to embrace leading-edge technologies. These innovative technologies generate better quality results while speeding up and optimizing tooling procedures.

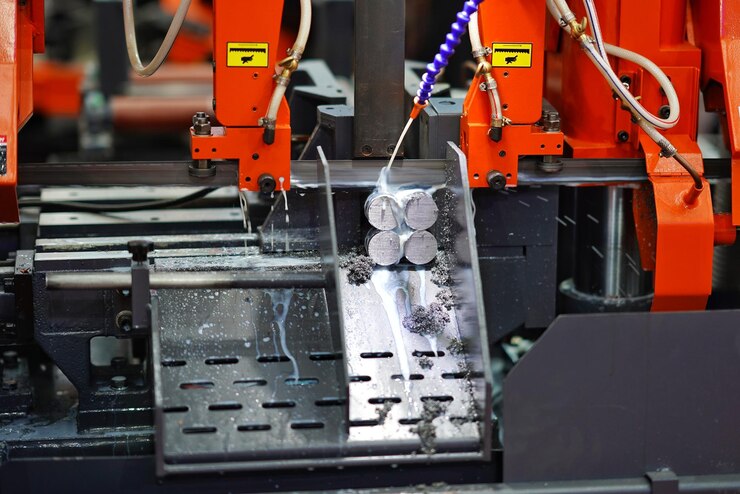

CNC Machining

CNC machining represents the primary technology employed by mold and die manufacturers to achieve their production needs. High-precision CNC machining processes all shapes of tools and parts through precise methods that maintain uniform results. Through this technology, manufacturers create essential molds that serve industries for injection molding casting production, and various fabrication processes.

3D Printing and Rapid Prototyping

Mold and die manufacturing processes experienced radical improvements through the introduction of 3D printing which created advanced capabilities for quick prototyping and inspection trials. Through prototype development suppliers reduce production delays while enhancing product design quality leading to better market launch times.

Die Casting and Forging

The production of metal components relies fundamentally on two industrial processes termed die casting and forging because they develop tools needed to shape molten metal products. The die-casting industry utilizes its specialized dies to make complex metal shapes and the forging industry depends on forged dies to manufacture strong steel parts for aerospace and automotive fields.

Why Choosing the Right Precision Mold and Die Supplier Matters?

Success in your manufacturing process depends heavily on selecting the appropriate precision mold and die supplier. A reliable supplier offers several advantages:

Improved Product Quality

Your products will pass strict quality inspections because of excellent tooling standards. Through their mastery of advanced technologies together with specialized expertise suppliers deliver tools that enable flawless consistent part production.

Cost Efficiency

Experienced suppliers enable businesses to minimize their production expenses. Tooling equipment of superior quality helps businesses cut down their production costs by lowering their waste generation and preventing expensive product rework.

Faster Time-to-Market

Fast manufacturing timelines together with quick finished product deliveries become achievable through the collaboration with dependable suppliers.

Increased Efficiency

When manufacturers adopt high-precision tooling they generate parts with less frequent mistakes which causes their production techniques to work both better and faster.

Customization and Flexibility

The precision mold and die suppliers serve the specific requirements of their customers through modified tooling solutions for plastic injection molding and metal stamping along with other tooling needs.

Why Does Ace Mold Stand as the Market-Leading Supplier?

Ace Mold brings honorable service excellence as a trusted precision mold and die supplier while delivering high-quality custom tooling solutions throughout the automotive alongside medical industries. Our extended decades of precision engineering enable our team to create exceptional molds and die which surpass the strictest requirements. Explore our website for more information about our capabilities: Ace Mold Precision Tooling Solutions.

On-Time Delivery and Excellent Customer Support

Manufacturing success crucially depends on production timelines and we recognize this fact. Our commitment at ACE includes proper delivery timelines for products so we remain dedicated to finalizing the shipping process jointly with our customers. Any time you need help regarding shipment tracking or other support issues our customer support team stands prepared to provide professional assistance.

OEM/ODM Services

ACE delivers extensive OEM/ODM business services to create tailored solutions that fulfill the detailed demands of various customer types. We serve customers through customized designs as well as specialized molds alongside additional service requirements.

Trusted by Our Clients

ACE has maintained over 96% customer loyalty since launching its business which demonstrates our position as a trusted industry partner. Our commitment to producing superior products and delivering excellent service alongside long-term customer connections brings entire business communities to trust our market leadership position worldwide.

More Than 3000 Successful Projects

ACE successfully finishes projects in the thousands so they are highly prepared to solve your business needs. Our extensive industry knowledge enables us to provide quality solutions that match multiple business requirements every time.

Why Choose ACE as Your Precision Mold and Die Supplier?

The competition fails to match the superior reliability features that ACE offers for its precision mold and die supplier services. ACE earned its status as a trusted business partner for twenty-five years through mold and molding expertise which supports diverse industries from automotive and medical to electronics. ACE stands as your number one choice to meet your precision tooling requirements.

Fast Response Rate

The manufacturing process requires time which ACE recognizes as essential for manufacturing operations. Our high priority is fast service delivery which leads to our organizational pride. We take quick action to supply necessary information after every contact through email or inquiry. Our team sends quotations back to you quickly during each business day so your operations don't face avoidable delays.

In-House Design and Development Team

Our internal design and development team provides clients with an advantage through custom project solutions. We possess expert engineers who provide instant solutions for custom molds and existing tooling modifications. Our ability to handle design work alongside development and production inside our facility enables us to deliver personalized solutions that meet your specific requirements through an efficient process.

Stringent Quality Control

Quality is our top priority. Every mold and die that ACE produces contains a comprehensive quality control system designed to achieve superior product standards. Each product goes through thorough inspection protocols throughout production and after production to maintain futile outcomes for our customers.

Competitive Pricing

Our business focuses on delivering superior value through our product offerings to customers. ACE maintains model and die prices that rival or exceed competitor costs while performing above industry standards for product quality. We maintain cost-effective manufacturing methods that generate major savings for customers while maintaining exceptional quality standards.

Conclusion

In today’s manufacturing world, precision mold and die suppliers are the backbone of high-quality production across numerous industries. From automotive tooling and medical device molds to aerospace and electronics tooling, precision mold and die makers play a pivotal role in ensuring that products meet exacting standards and are produced efficiently. By selecting the right precision tooling partner, businesses can reduce costs, enhance product quality, and accelerate time-to-market. With advanced technologies, customizable solutions, and a commitment to excellence, precision mold and die suppliers are invaluable assets to any manufacturer.