Precision Mold Making for Automotive: Enhancing Quality and Performance

The automotive industry succeeds because precision mold making enables manufacturers to produce parts that are concurrently high-quality and durable along with cost-effectiveness. Manufacturers working in the automotive sector require components that fulfill strict requirements regarding operational standards and engineering safety alongside attractive design. This article explains why precision mold making for automotive industry and demonstrates the involved technologies while examining its impact on high-end automotive part development.

What is Precision Mold Making for Automotive?

The process which combines design with detailed manufacturing of molds requires absolute measurement precision. Production facilities use these mold designs to make components ranging from exterior pieces to interior fixtures along with components for automotive engines. Companies use molds as a production tool to minimize tolerance errors and generate superior quality parts that perform better and maintain longer durability.

In automotive production precision mold making stands as an essential requirement because minor mold defects cause corresponding defects throughout automotive parts. Rigorous testing methods evaluate automotive elements that directly affect both vehicle security operations as well as operational capabilities. Every automotive mold including both dashboards and high-precision engine parts needs to fulfill precise design specifications to deliver optimal part performance.

The Role of Precision Mold Manufacturing in Automotive Production

High-quality needs in the automotive industry require precision mold manufacturing for essential performance. Mold manufacturing encompasses detailed design projects that need both innovative engineering tools experienced manufacturers and sophisticated production methods. Here's a closer look at how precision mold-making is integrated into automotive production:

Automotive Interior Molds

Precision molds that produce dashboards door panels and center consoles deliver both flawless fitments alongside superior finish quality. These structural elements require compliance with safety standards while maintaining physical appearance quality. The exact specifications of vehicles determine each curve edge while all features are precisely designed through precision mold manufacturing.

Automotive Exterior Molds

Exact precision mold-making techniques are necessary throughout the manufacturing process of exterior components which include bumpers together with grilles and headlamps. These exposed components need dual characteristics of durability and operational functionality because they encounter severe weather conditions. High-precision molds enable precise manufacturing of each component which supports both vehicle design functionality together with overall performance standards.

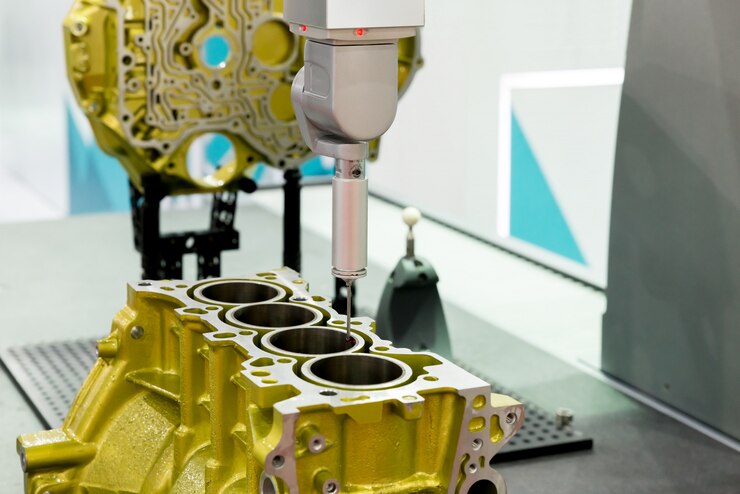

Engine Compartment Molds

Manufacturing the parts within the engine compartment area including air ducts cooling systems and engine covers requires absolute precision mold-making standards. Technical components require longevity under harsh temperature conditions together with the capability to resist mechanical pressure. Engine components of high-quality result from advanced mold-making practices that combine high-temperature tooling with gas-assisted injection molding.

Underbody and Structural Molds

The underbody structures of vehicles maintain overall vehicle stability and protection systems. Precise molds made for automotive underbody components result in correct strength alongside proper fitment for frames floor panels and structural supports. These molding operations need complicated engineering specifications that sustain vehicle structural requirements.

Lighting System Molds

Automotive manufacturers need precise modeling solutions for lighting elements such as headlamp subsystems and taillights which require functional performance and appearance fulfillment. The manufacturing process of precise mold design allows exact control of illumination distribution and mechanical endurance together with custom-fit integration without affecting safety systems or design quality within the vehicle construction.

The Technique Set-up for Exact Mold Creation Impacting Automotive Fabrication

The Automotive component precision mold-making methods have progressed tremendously in recent years. Today's advanced mold-making techniques provide producers with elevated accuracy levels during shorter manufacturing timelines and superior resulting product quality. Below are some key techniques used in precision automotive mold making.

Injection Molding for Automotive Parts

The automotive mold-making industry depends heavily on injection molding procedures for its production activities. Manufacturers insert hot melted plastic into special molds until the captured material cools into finished components inside the cavities. Injection molding serves well for creating numerous vehicle components that occupy both interior and exterior divisions. Plastic injection molding enables precise automotive part manufacturing because it delivers economical yet efficient production capability for creating elaborate automotive designs.

Two-Shot Injection Molding

Through a two-shot injection molding process, machine operators supply two distinct materials sequentially to a unified mold section to build components with multiple material zones. The technology delivers exceptional benefits for automotive products requiring different material combinations between flexible parts strong structural elements and durable components. The process of two-shot injection molding produces automotive door panels with integrated soft-touch surfaces alongside rigid structural engineering resulting in enhanced functional integrity and esthetics.

Benefits of Precision Mold Making for the Automotive Industry

The application of precise mold engineering for automotive components yields multiple advantages that enhance performance while ensuring vehicle safety together with economic efficiency. Let’s explore some of the major advantages:

Improved Part Quality

Through precision mold technology the automotive sector achieves parts that guarantee exact dimensions along with exceptional surface quality. The high dimensional precision in mold manufacturing directly leads to better vehicle quality which minimizes defects alongside reduced product rework expenses.

Cost Efficiency

Precision mold making requires substantial initial investments which pays off by decreasing waste output and optimizing production speed. Today's advanced molds produce excellent accuracy so the number of rejected pieces decreases while production duration decreases along with material expenses.

Enhanced Durability and Performance

The production of precision molds follows established performance criteria. Automotive components fabricated through precision molding processes display heightened durability together with operational stress resistance. Through precision mold manufacturing each automotive part receives construction that enables longevity.

Customization and Flexibility

The advanced capabilities of precision mold manufacturing enable manufacturers to produce customized molds that fit distinct automotive configurations accurately. Manufacturers utilize specific design requirements or material needs to develop their mold structures which ensure each vehicle receives a perfect fit for its parts.

Faster Production Times

Production efficiency increases along with reduced cycle times because advanced mold-making approaches including hot runner molds and gas-assisted injection molding provide manufacturers with these benefits. Automotive companies effectively complete short deadlines by sustaining exceptional quality through production with this approach.

How Ace Mold is Leading the Way in Automotive Precision Mold Making?

Ace Mold delivers industry-leading precision mold solutions that serve automotive manufacturers across the board. Our automotive mold-making expertise extends throughout the complete development lifecycle to generate exceptional quality mold solutions aimed at a full spectrum of automotive components. The experienced craftsmen at our facility maintain exacting standards to produce every automotive part specifying precision mold tooling for interiors as well as high-quality injection molds for bumpers and custom mold solutions for headlamp applications.

We provide automotive customers with three advanced manufacturing capabilities consisting of automotive high-speed mold making combined with micro-injection molding for the automotive sector as well as automotive over-molding solutions. Ace Mold dedicates itself to supporting manufacturers reach their production targets through superior automotive mold solutions that match both quality standards and efficiency requirements and cost reduction demands. You can find additional details on our precision mold-making services at Ace Mold.

Conclusion

Precision mold making is a critical process in the automotive industry, directly influencing the quality, performance, and safety of automotive components. With the continuous advancement of mold-making technologies, manufacturers can produce high-quality, durable parts with minimal waste and reduced production costs. By choosing an experienced and innovative partner like Ace Mold, automotive manufacturers can stay ahead of the competition and deliver vehicles that perform reliably on the road.