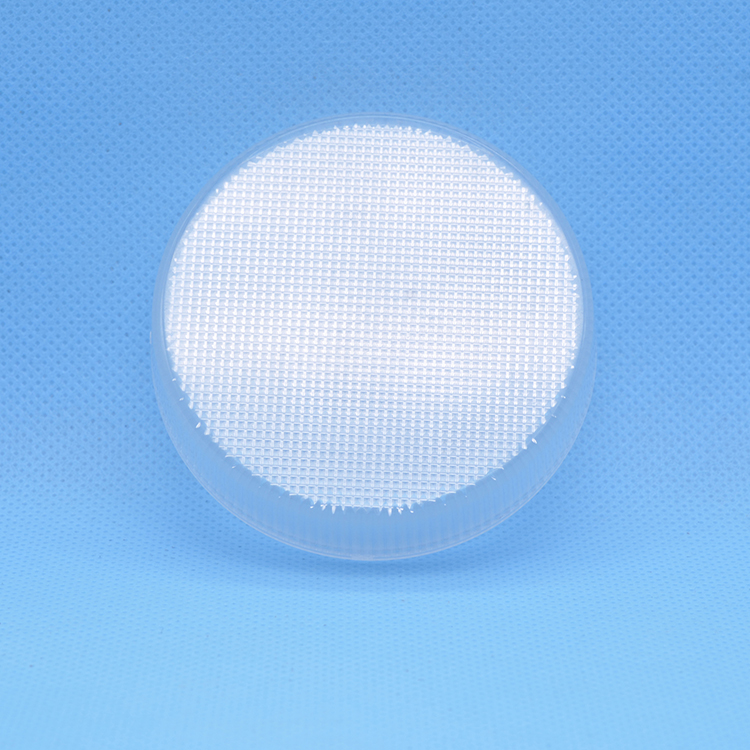

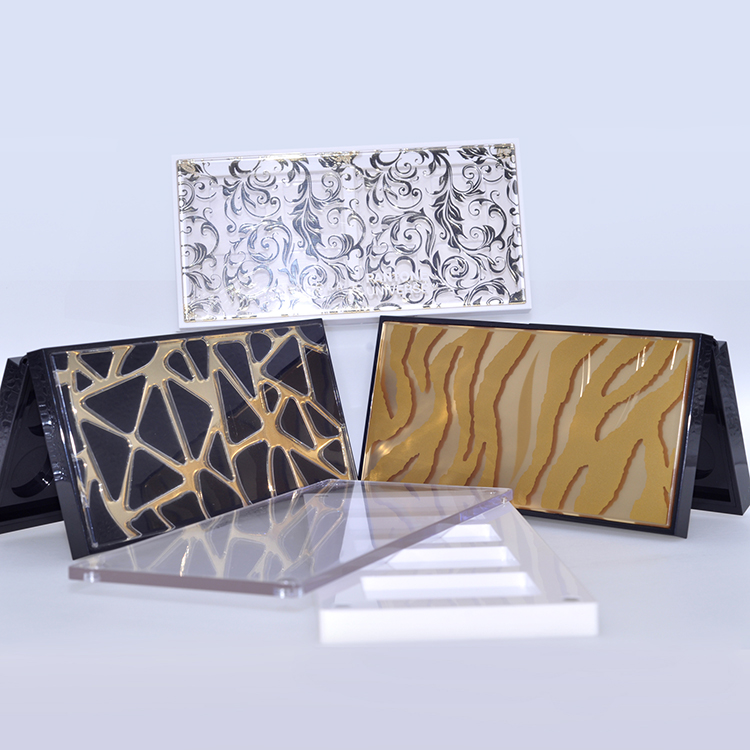

Cosmetics Injection PP Plastic Mould

Cosmetic injection molding is one of the most popular and effective methods of producing high-quality plastic parts and components. It is used in a variety of industries, including automotive, medical, and consumer products. Injection molding is a process by which plastic is heated and forced into a mold, which then cools and solidifies the plastic into the shape of the mold. This process is used in the production of many consumer products such as plastic bottles, containers, and caps.

ACE has been a major supplier to some of the most well-known OEMs of cosmetics product plastic parts. ACE's comprehensive resource infrastructure enables our clients to concentrate on what matters most in the cosmetics product plastic parts market—zero defects and lower overall costs.

Benefits of Using Cosmetics Injection PP Plastic Moulds

Cosmetic injection moulding is a great way to produce high-quality, aesthetically pleasing products with minimal effort. It has many benefits, including cost savings, time savings, and improved product quality. PP plastic moulds can be used to produce a variety of cosmetics, such as lipstick, eyeshadow, nail polish, and lip balm.

Quality: Cosmetics injection PP plastic moulds can be an important factor in creating high-quality products. Investing in quality moulds will help ensure that the product is of a consistent and precise shape, size, and design. The quality of the moulds can also help extend the life of the product, reduce product waste, and increase production efficiency. The quality control of these moulds is critical because the quality of the moulds affects the quality of the product.

Eco-friendly: Eco-friendly plastic moulds are an excellent choice for producing cosmetics products. They are made from recyclable materials and are designed to minimize waste and pollution. They are also lightweight, durable, and cost-effective. Additionally, they are easy to use and can be customized to meet the needs of any cosmetics brand. s. This type of plastic is recyclable and does not contain toxins, making it a much better choice for the environment. The moulds are also very durable and can be used for a variety of cosmetic products.

Flexibility: Cosmetics injection PP plastic mould flexibility is an innovative way to enhance the quality and appearance of cosmetic products. The flexibility of the mould allows for a more precise and consistent application of the product, resulting in a higher level of customer satisfaction. The injection moulding process allows for a high degree of flexibility, which in turn can result in a quicker, more cost-effective production process.

Why Choose ACE Group

1. We have an in-house design and development team with extensive experience. We are very familiar with and skilled at dealing with our international clients.

2. We offer OEM/ODM services to all types of customers, and our professional customer support and project management teams are available 24 hours a day, seven days a week.

3. We have a strict quality control system in place to ensure the highest quality of our products, the best service, and the most competitive prices.

4. Quality inspection samples are always available and can be sent to you quickly.

5. Design ability: design in accordance with customer specifications.

6. We deliver goods on time and work with customers in a transparent manner.

| Brand Name | ACE |

| Model Number | ACEBLOW0008 |

| Multi Injection | Single / Double / Multi color |

| OEM/ODM | Acceptable |

| Mould Base | LKM, HASCO, DME, etc |

| Injection System | Hot runner / Cold runner |

| Cavitation | Single / Mutil Cavites |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |