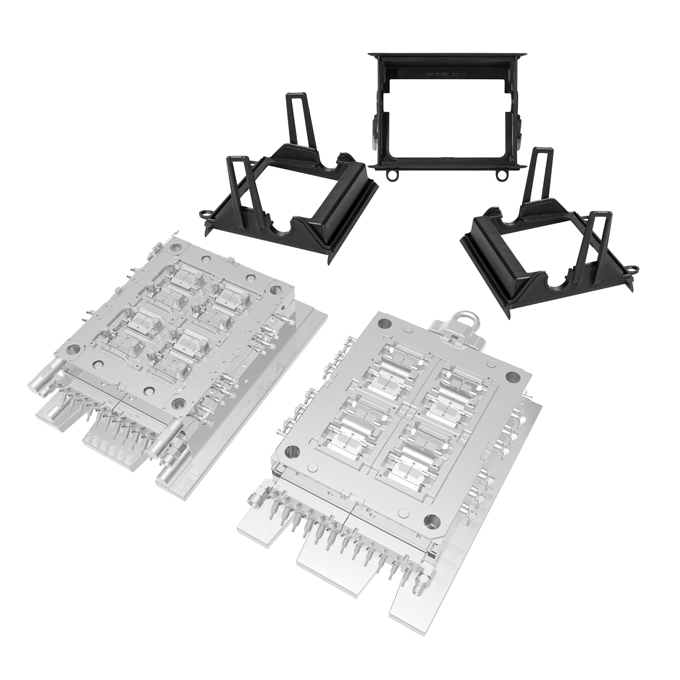

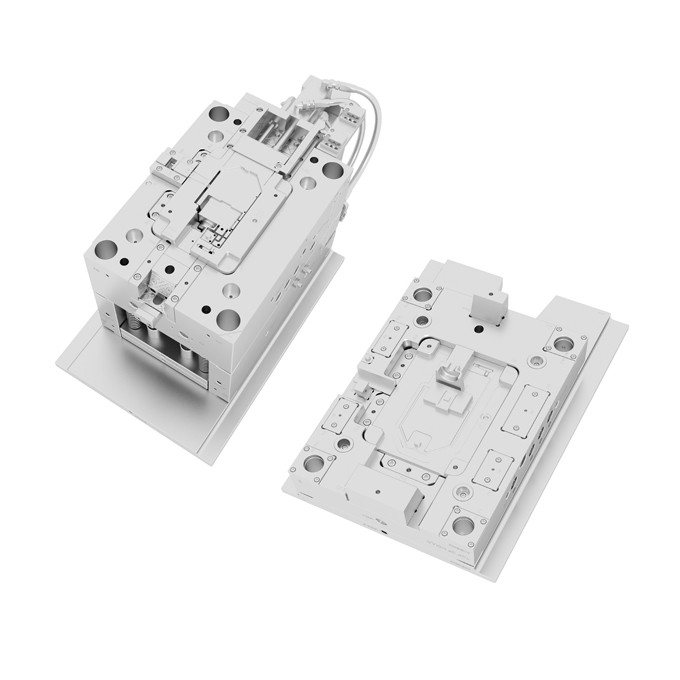

Home Appliance ABS PP Plastic Injection Mould

Home appliance ABS PP plastic injection moulds are quickly becoming the go-to choice for many manufacturers as they offer a variety of benefits when it comes to producing home appliances. ABS PP plastic injection moulds offer greater strength and durability, improved design flexibility, and cost savings when compared to other materials.

ACE has been a key supplier to some of the most well-known manufacturers of home appliances and office supplies. ACE's comprehensive resource infrastructure enables our clients to focus on what matters most in the home appliance market: zero defects and lower overall costs. We can construct the following household Product parts:

- Product for the home.

- Injection parts for washing machines.

- Product for the kitchen.

- A printer for the office.

- Computer.

- Any food container with a thin wall.

Benefits of Home Appliance ABS PP Plastic Injection Mould

Home appliance ABS PP plastic injection moulds offer a variety of advantages in terms of cost-effectiveness, efficiency, precision, and durability. These moulds are suitable for the production of a wide range of products and can be used in a variety of applications. The use of Home Appliance ABS PP Plastic Injection Moulds is a cost-effective way to create attractive and durable products. These moulds provide superior strength, superior detail, and superior dimensional stability. They are also easy to use and require minimal maintenance.

Versatility: Home appliance ABS PP plastic injection molding is becoming increasingly popular for the production of various home appliances. This versatile process offers a range of advantages over other production methods, including cost-efficiency, higher quality, and greater design flexibility.

Cost-efficiency: Home appliance ABS PP plastic injection molding is a process used to manufacture high-quality plastic parts for a variety of products, including home appliances. The process involves heating the plastic material to the right temperature, injecting it into a mold, and then cooling it off to create the desired shape.

Performance: Home appliance ABS PP plastic injection molding is an increasingly popular way to save money and improve performance with home appliances. This type of injection molding is used to produce parts for a wide range of home appliances such as washing machines, dishwashers, refrigerators, and more.

Why Choose ACE Group

1. We have a highly experienced in-house design and development team. We are very comfortable and skilled in dealing with our international clients.

2. We provide OEM/ODM services to all types of customers and have professional customer support and project management teams on hand 24 hours a day, seven days a week.

3. We have a strict quality control system in place to ensure that our products are of the highest quality, that we provide the best service, and that our prices are competitive.

4. Quality inspection samples are always available and can be quickly delivered to you.

5. Design ability: create designs that adhere to customer specifications.

6. We deliver goods on time and work transparently with customers.

| Brand Name | ACE |

| Model Number | ACE Mould |

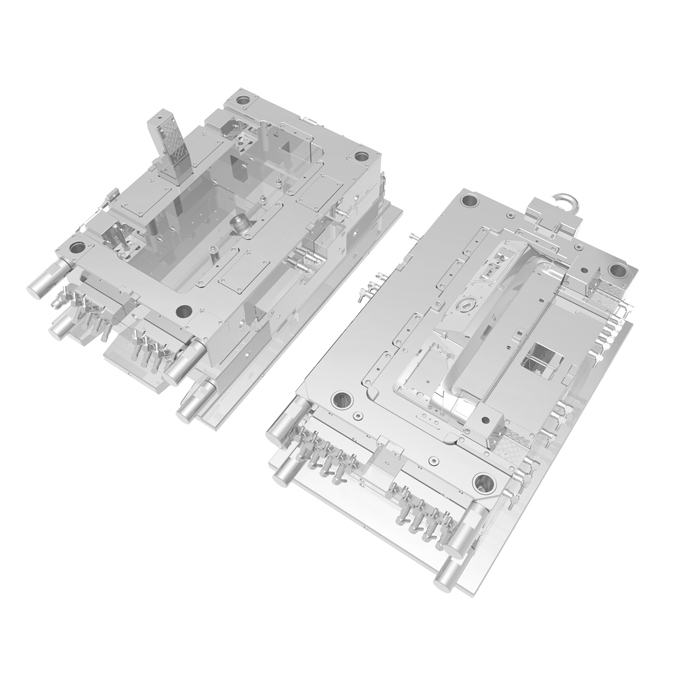

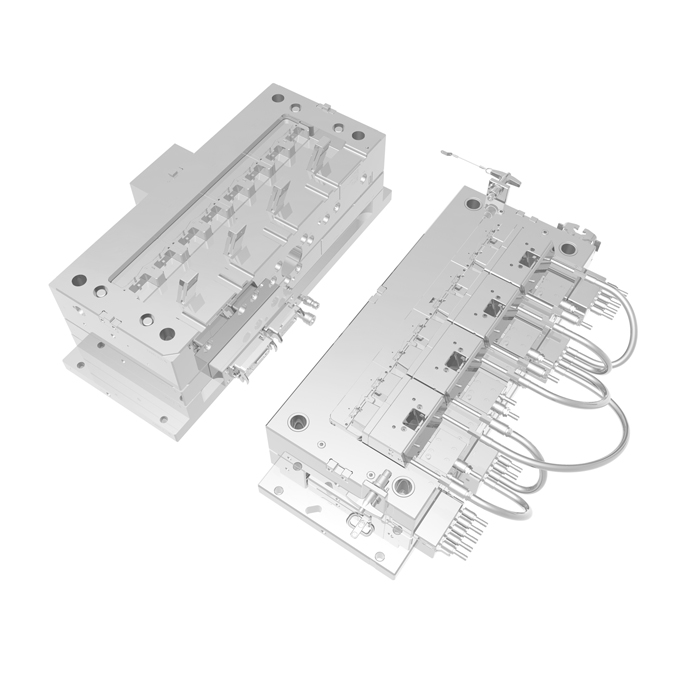

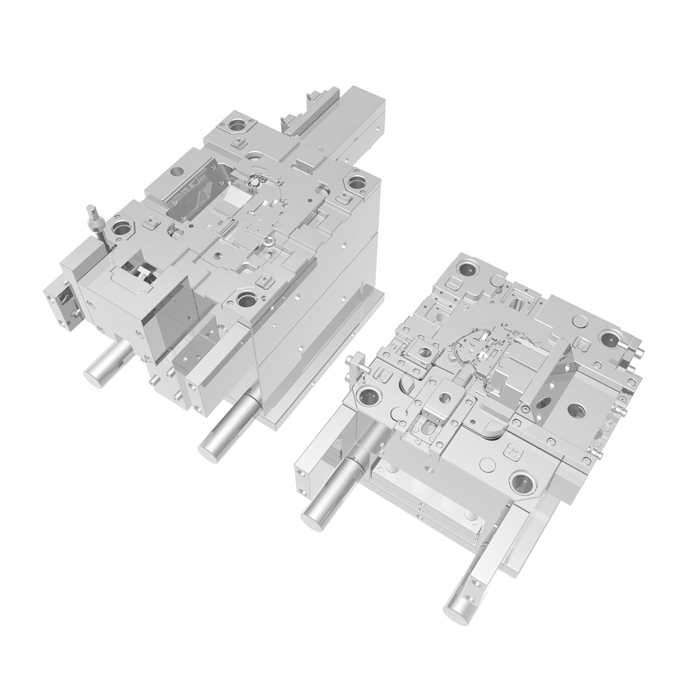

| Mould Material | P20 / 718 / 738 / NAK80 / S136 / 2738 / 2316 |

| Mould Shaping | Plastic injection moulding |

| OEM/ODM | Acceptable |

| Mould Base | LKM Mould Base |

| Surface Treatment | Mirror Polish |

| Design Software | UG, PROE, CAD, SOLIDWORK, etc |

| Tolerance | +/- 0.01mm |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |