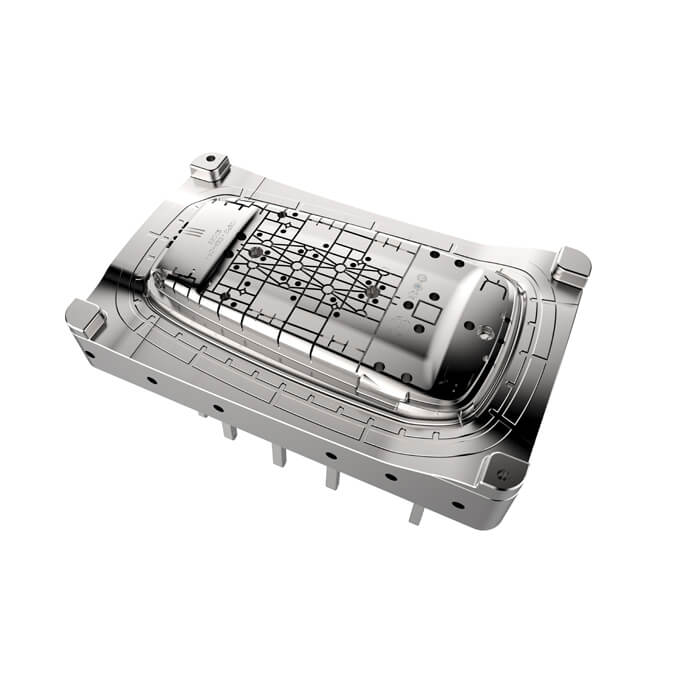

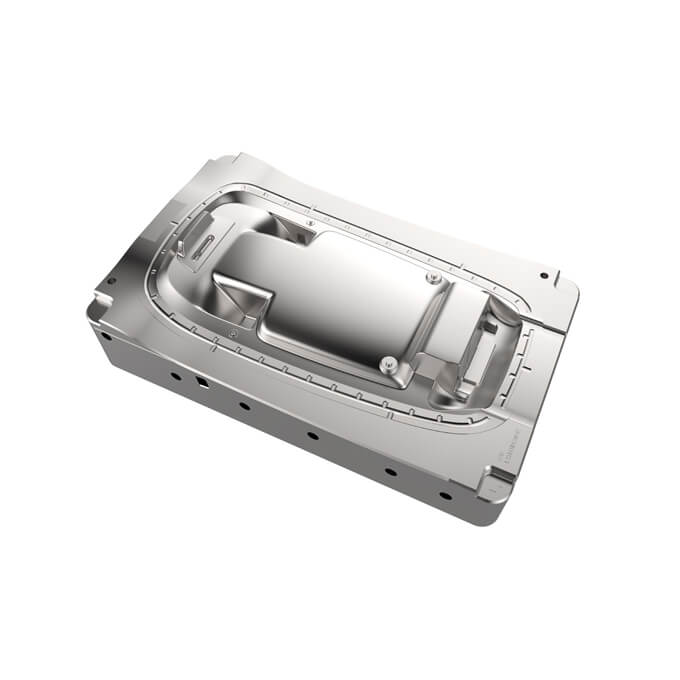

Plastic Die Mould Components Accessories

Plastic die mould components and accessories are essential in producing plastic products. These components are made from a variety of materials and are used for various purposes, such as creating moulds, cutting shapes, and forming parts. ACE has been a key supplier to several well-known automotive OEMs. ACE's comprehensive resource infrastructure enables our clients to focus on what is most important in the automotive market: zero defects and lower overall costs.

Benefits of Medical Plastic Transparent Parts

Plastic die mould components accessories provide a variety of advantages for product manufacturers. These include increased accuracy, lower production costs, and a reduced risk of defects in the finished product. In addition, plastic die mould components are easy to customize and can be used in a wide range of applications.

Plastic molding components and accessories are essential for any successful plastic injection molding process. They are an integral part of the process and can often be the difference between a successful product and one that fails.

Low maintenance: Plastic Die Mould Components are highly efficient, low maintenance components used in a variety of industries for producing quality plastic parts and components. They are made from high-grade materials and are available in different sizes and shapes. The components are easy to install and use, and they can be tailored to suit specific requirements.

Durability: Die mould components are an integral part of the die moulding process, and their durability is essential for the successful operation of the process. The durability of die mould components is affected by factors such as the material used, the manufacturing process, and the operating environment.

Performance: Optimizing the performance of plastic die mould components is vital for ensuring the highest quality output and the most efficient production process. Plastic die mould components are a vital part of the manufacturing process, as they help shape and produce the parts needed for a product. They can help improve product performance in a variety of ways, from providing a perfectly shaped product to reducing manufacturing costs.

We can manufacture the following automotive components:

- Rear seat

- Deckilid edging

- Inside doorknob

- Door casing

- Engine components

- Roof components

- Lighting components

- Mud guard components

- Bags of air

- Components of an air conditioner

Why Choose ACE Group

1. We have a highly experienced in-house design and development team. We are very comfortable and skilled in dealing with our international clients.

2. We provide OEM/ODM services to all types of customers and have professional customer support and project management teams on hand 24 hours a day, seven days a week.

3. We have a strict quality control system in place to ensure that our products are of the highest quality, that we provide the best service, and that our prices are competitive.

4. Quality inspection samples are always available and can be quickly delivered to you.

5. Design ability: create designs that adhere to customer specifications.

6. We deliver goods on time and work transparently with customers.

| Brand Name | ACE |

| Model Number | ACE00035 |

| Material | ABS, PC, PEEK, ULTEM |

| Shaping Mode | Plastic injection moulding |

| Mould Standard | DME or HASCO |

| Surface Treatment | Texture, Polishing, Coating, Painting |

| Surface Request | EDM or High Polish |

| Injection Moulding Process | Horizontal Injection |

| OEM/ODM | Acceptable |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |