Blow Mold Process; A Guide To Everything You Need To Know

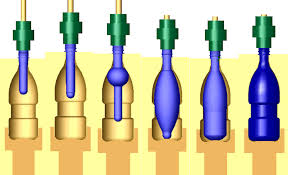

The blow mold processes have revolutionized the world of plastic manufacturing. It offers multiple processing techniques to fabricate the finished products. The process is similar to injection molding however it is less expensive. The major processes include the heating and melting of the plastic materials, producing the parison. This parison then goes to the mold cavity and acquires the desired size and shape. Then a high pressurized air goes inside the cavity and freezes the product to impart the shape. The desired product then leaves the process and the blow molding performs the secondary operations.

You May Also Read: China Mold Maker: 5 Types of Plastic Injection Molds

The blow molding process has its advantages and disadvantages. But as its operation is easy and convenient it is one of the most adopted plastic manufacturing techniques. This article provides a detailed introduction to the blow molding process.

Introduction To Blow Mold Processes

The blow molding process is a technique to create hollow objects. The small objects include bottles for engine oils, water, milk, shampoo, liquid soaps, etc. It can also formulate large containers i.e. Plastic tubs and drums, and storage tanks. The process is similar to injection molding but the pressure limit is much lesser than the injection molding.

The process first involves the heating of materials and makes the material into a molten form. The molten form of the material is parison which then goes to the mold cavity and acquires the shape of the cavity. Then a pressure of up to 25 to 150 psi forces the material to form the desired shape.

Types Of Blow Mold Processes

There are several types of blow molding processes out of which three are the most popular. The processes only differ in the parison melting, formation, and movement otherwise the basic principle remains the same.

EBM Or The Extrusion Blow Molding

The Extrusion Blow Molding makes high-quality plastic bottles, jars, and jugs. It deals with multiple plastic types like HDPE, PP, PVC, PC, PETG, etc. It is the simplest form of blow molding. The process first involves the formation of the parison. There is an extruder that extrudes the hot parison into the cold mold cavity. The operation then seals the mold and injects the air. This pressurized air allows the material inside the cavity to freeze and therefore acquires the desired shape.

If the desired products need coloration, the process allows adding the required coloration to the grains or plastic pellets. When the process fabricates the desired finished product, the residual unused material needs removal so this type of blow molding also takes care of this flash. Moreover, it also performs secondary treatments which include flame treatment, mold decoration, and leak detection.

IBS or The Injection Blow Systems

The injection blow molding is similar to the extrusion blow molding except for the parison formation. The parison in this type uses injection molding techniques to form parison. This technique is excellent for fabricating high-quality finished products and provides wide variations in contrast to the extrusion molding. Once the parison acquires the mold's shape, the inflated air passes into the cavity and thus fabricates the desired shape product. After the blowing process, the ejection takes place and safely ejects the article after performing leak testing.

Injection Stretch Blow Molding

Injection Stretch Blow Molding involves four processes to fabricate the finished product. The process first involves the melting of material into the parison. This parison then goes to the mold cavity and acquires the shape of the mold and formulates the inner and the outer diameter. Once the parison gives attains the shape it then experiences stretching and blowing.

The parison passes around the rod which stretches it to the desired length and undergoes a high pressure. After the set time, the mold opens and ejects the product out of the cavity.

Advantages Of The Blow Mold Processes

The blow mold processes offer a wide variety of advantages. Here is a list of a few of the many advantages it provides.

Revolutionary Technique

We use hundreds of products made up of plastics in our daily lives. The blow molding techniques have highly revolutionized the manufacturing and fabrication technologies. Every industry now employs this technology to fabricate a wide variety of finished products of the desired shape and size. The blow mold process is one of the most convenient ways to fabricate the finished products.

Wide Variety Of Finished Products

Another advantage of the blow mold process is that it allows the production of finished products with different shapes and sizes. Hence products from milk, water, oil, and liquid soap bottles to oil containers and drums, the manufacturing of all these unique shaped containers are possible only because of the blow molding techniques.

Reduced Costs

The process employs pressure much lesser than the injection molding techniques, hence it is more economical. Moreover, the operation of the blow mold processes is fully automatic and works on robotics, hence requires no human intervention. This helps to reduce labor costs. Therefore, the blow mold techniques can produce a wide variety of desired product with comparatively lower investments.

Multiple Methods For Production

As mentioned above, there are multiple processes to fabricate the finished products. The extrusion molding allows the production of materials just like glass blowing which involves blowing of material in the extruder. The injection blow systems work exactly like the injection molding in more economical cost expenditure. The process employs low pressure hence it is less expensive than injection molding. Lastly, the injection stretch blow molding allows stretching the material to achieve the desired shape and size.

Increased Production

The blow mold processes are fast and quick manufacturing processes and allow mass production of the finished products. It is easy and convenient and can produce a large number of finished products. It is the fast operation of the blow molding technique that has made its use popular in plastic manufacturing industries. Moreover, large quantities of products can be fabricated in one single cycle.

Automatic Operation

Another key advantage of the blow mold process is its automatic operation. It does not involve human intervention and works on the principles of robotics. The process has been developing by leaps and bounds and now involving the 3d manufacturing techniques, which makes them a promising dominant plastic manufacturing technique.

Disadvantages Of The Blow Molding Process

Every technology involves both pros and cons. The blow molding technique has various advantages that we have already discussed. However, it does have disadvantages as well.

Dependency On Petroleum

The blow molding process works on petroleum products like the other major industrial processes. This dependency can cause a deficiency in the petroleum reserve.

Impact On The Environment

The process itself is environmentally friendly, but the plastic it produces is biodegradable. Hence extreme plastic production is a serious threat to marine life and our environment.

Clichéd Production

Although the process is highly reliable in plastic manufacturing, it can only deal with the hollow product formations. It might become difficult for the process to deal with the thick-walled objects.

You May Also Read: Importance of Prototype Tool in Injection Molding

Conclusion

To sum up, the blow mold processes are excellent to fabricate finished plastic products of the desired shape and size. The process involves heating and melting of the plastic grains into parison which then goes to the mold cavity and attains its shape. The best thing about blow molding is its low-cost fabrication and automatic operation. Hence there are no chances of error as there is no human intervention and no labor involvement. The upcoming blow Molding techniques involve 3D technology that makes the future of blow mold processes dominant and promising.

For More Information, Contact Us Today!