Precision Mold Companies: Promoting Innovation in Industrial Processes

In this article, we will discover what precision mold companies are why they are relevant, and their technologies. Also, we will focus on why it is crucial to choose the right precision mold manufacturer, and how your business can gain from custom molding.

What are Precision Mold Companies?

Precision mold companies are leading manufacturing companies that conduct the manufacturing of molds with optimum precision. These molds are after that employed in a number of processes, especially plastic injection molding. The aim of precision molding is to produce end parts that will be accurate, flawless, and of high quality.

Services Offered by Precision Mold Manufacturers

Precision mold manufacturers serve clients in various industries by providing various kinds of services to suit their needs. These services typically include:

• Custom Mold Manufacturing: Special services to design and develop specific molds for purposes of manufacturing specific products.

• Injection Molding Services: Semi and fully automated large-scale processes of creating three-dimensional visuals through injecting molten material into a mold.

• Mold Design & Engineering: The complexity of molds as a method of achieving high efficiency and good quality of end products.

• Tool & Die Fabrication: Forgan building the utensils used in the molding process.

• High Precision Molding: Applying the latest technologies and superior materials to attain tightly integrated work and accuracy on the eighth level in every mold.

ACE Mold: Lead as One of the First Precision Mold Companies

At ACE Mold, precision molds and molding service is our mission and focus and it is the promise we make to our clients across the world. For many years we have been recognized as one of the leading providers of precision molds manufactured in Mainland China, with a single-minded focus on providing global quality performance. Here’s why our clients continue to choose us for all their molding needs:

High-Quality Products

Good quality is indeed the cornerstone of our work. At ACE Mold, molds are produced to intricate specifics, with detail, and a professional touch. Thus, the high-quality inspections and examinations carried out in our company guarantee very low levels of defects and prime quality. Regardless of whether you are in the medical, automotive, or consumer goods industry, you can be sure that our products will meet and even surpass your expectations.

Industry Experience

Accumulated from our team of experienced staff, we have gathered comprehensive information on precision molding and the various requirements of different fields. With such a background, we are able to offer a highly specialized service as well as ensure our clients are offered the best of services time and again.

Mature Technical Team

Our experienced engineers and designers work to provide the best and most creative services in the frames of the project. They possess profound technical skills and years of experience to offer you the right molding services for your projects.

Competitive Pricing

ACE Mold understands that costs are critical to its consumers, and therefore we sell our products at pocket-friendly prices. With such an expert and professional group of designers the supply chain and low overhead costs, I promise to deliver quality products to fit your pocket.

Find out why professionals choose ACE Mold to produce their precision molds – let ACE Mold be your partner in providing efficient and qualitative manufacturing of molds.

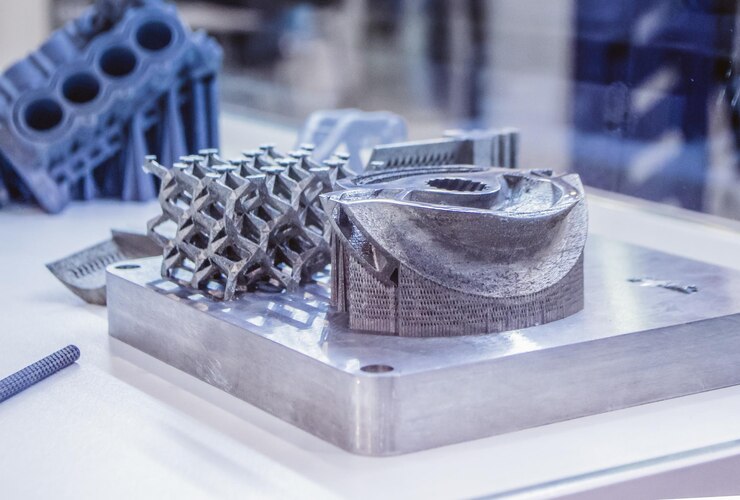

The Technologies Used in China Precision Mold Industry

Advanced CAD/CAM Systems

The use of CAD/CAM systems has become common with many industries producing precision molds using the newest technology to build precise molds. These systems assist the mold designers to have a perception of the final product besides adjusting some aspects to fit in the production.

Injection Molding Machines

Injection molding machines are used to force molten plastic or metal into a mold to develop parts. These are sophisticated equipment that is created to perform with even the smallest tolerances since each component that makes up the assembly needs to possess specific characteristics.

Automation and Robotics

Precision mold companies have benefited from the use of robotic systems in production, as well as automated technologies to minimize human interventions. Automated technology helps to guarantee that each stage of the molding process is met, including the molding process and the post-process.

Advantages of Hiring Precision Companies

When choosing a precision mold companies, there are several key benefits that companies gain access to:

Enhanced Quality Control

Precision molding is all about paying very close attention to the sizes that form the products. High-precision molding firms make sure to produce parts that meet expectations, thus increasing reliability and minimizing the production of scrap parts.

Faster Time-to-Market

Because of the high level of technology applied and professionalism of the mold-making firm, businesses can expect a shorter lead time. Rapid prototyping and enhanced machines prove useful to growing product speed more so in industries with restricted time limits.

Cost-Effective Production

Another advantage of precision molds is that even though they cost more initially, it may take a relatively shorter period of time for the difference to be rounded off the general production expenses. Superior molds withstand wear and tear and deliver fewer faults; together these mean minimal scrappage and material losses.

Versatility Across Industries

As highlighted before, precision mold firms are relevant in diverse industries as explained below. These manufacturers can offer medical molding or automotive molding and deliver customized services that are perfect for different industries since their products are made of the right material, functionality, and design.

What You Should Look for When Selecting a Precision Mold Firm?

Expertise and Experience

The experience of a precision mold company must also be checked so that it can be seen if they deal in your areas of operation. For instance, if you work in the medical device industry you want to find a company that specializes in medical molding that has insight into laws that govern such business and the materials allowed to be used.

Technology and Equipment

The company you will select should employ the latest technologies in molding. See if they employ the latest CAD/CAM software, high-accuracy injection molding machines, and the finest technology in prototype development.

Quality Assurance Practices

Whenever you engage a precision mold manufacturer ensure that they possess sound quality procedures that would guarantee quality molds. Ask them if they are certified for ISO 9001 and enquire about their quality control test.

Cost and Lead Time

Like quality, cost and time are aspects of the same significance. Make sure that the precision molding company is in a position to meet your production schedule without going over your budgetary estimates.

Conclusion

As industries continue to demand greater precision and higher quality standards, the importance of precision mold companies cannot be overstated. At ACE, we specialize in providing high-precision molding solutions that meet the unique needs of your business. From custom mold manufacturing to advanced injection molding services, our expert team is committed to delivering the best results on time and within budget.