What is mold flow?

Mold flow may be a maker of an asynchronous computer program for tall conclusion plastic infusion molding as well as computer aid designing. Autodesk is its owner. Autodesk steady discharge is a flow of mold.

Form stream examination is the method of reenacting an infusion molding cycle with a specific plastic and examining the outcomes. Shape stream examination ought to happen sometime recently the infusion molding prepare ever starts, through the utilization of a specialized program that recreates the plan of the portion which is fabricating.

What is mold flow insight?

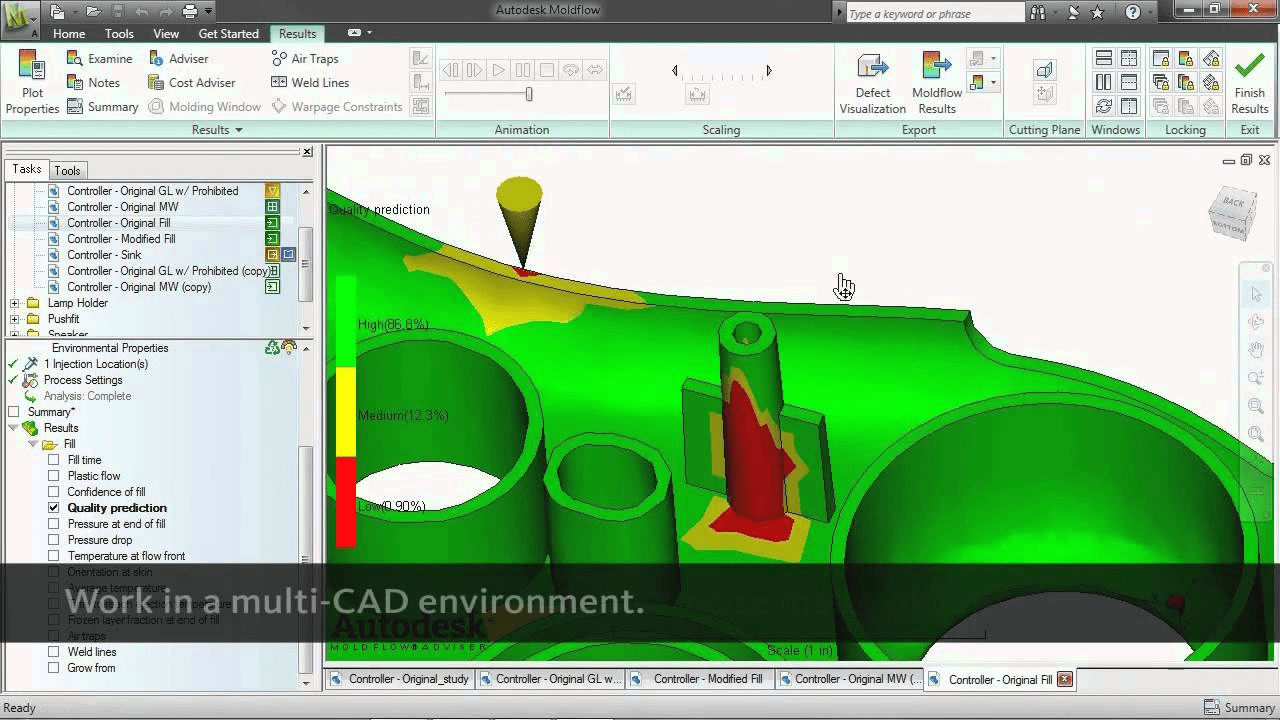

Whereas little reenactment arrangements concentrate on the examination of the portion, Autodesk mold flow insight permits the going with recreation over the whole handle chain. With Autodesk form stream understanding you’ll be able to approve and optimize components, molds, and forms, independently and avoid potential and their reasons.

What is a mold flow adviser?

Autodesk Moldflow is the little and expense-effective arrangement for mimicking the plan amid the component improvement. With the coming of computerized models, improvement times and costs can be decreased.

Regularly as it were inside several minutes. Despite the greatly straightforward dealing with, the counsel employment capacities, solvers, and overall, the Autodesk mold flow understanding fabric database, which has above 10,000 information records.

The council permits the straightforward consequence of CAD information from total common frameworks like Creo®, Catia®, or Solid works®, and the quick recreation of the part.

How do I make a mold design?

A shaping plan is an imperative portion of the improvement preparation when considering the generation of a new shaping. Here are some basic steps for a mold design.

The shape of the material

The shape of the shaped portion includes a coordinate bearing on the time included in making the shape, the cycle time for the shaping. For illustrations, undermines as well as profound screw strings frequently need a partitioned moving portion which increments the cycle time of each shaping operation.

Points on the side dividers are fundamental to guarantee the forming which can evacuate from the shape.

The surface finish of the molding

The surface wrap-up of the shaping should be chosen sometime recently the shape is done. Embossing, carving and other wraps up can be included in the shaping to upgrade the stylish qualities of the forming. Any flaw on the wrap-up of the shaping will exchange to each shape made.

Pressure, surface zone as well as thickness of the forming straightforwardly influence cycle time. Where shaping has altogether shifting thickness, cooling must be controlled exceptionally carefully something else sorrows frame (sink marks) on the external surface of the shaping caused by top shrinkage of the thick segment of the forming.

The cavity of the shape

The number of cavities in a shape is administered by the per annum unit needed. The number of cavities straightforwardly influences the measure of the machine needed for multi-cavity shape. This in turn influences the taken toll of the form and the unit expense of the shaping. In the end, hot runner frameworks have ordinarily utilization for the multi-cavity system. You can see how mold flow is important.

Labeling of the shape

Require for embed or name to insert amid the forming group needs to consider at the shape plan stage. All infusion molds need a focus or focuses at which the liquid plastic is presented into them.

On the off chance that has no consideration at the plan organizing, this may take off unattractive flaws on the wrap-up forming. Which require an encouraging arrangement to expel them, bringing about additional costs. Finally, by following this procedure you’ll be able to create

How do you make an injection mold?

Infusion molding is the method of creating custom pliable components by infusing liquid plastic fabric at a tall weight into a metal shape.

Similar, to other shapes of plastic forming, after the liquid plastic is infused into the shape, the form is chilled as well as open to uncover a strong plastic component. The handle is similar to a Jelly shape which is filled at that point chilled to make the ultimate item.

Common uses of injection molding

Infusion molding has commonly utilization for making the exceptionally tall volume of custom pliable components. An expansive infusion-forming machine can shape car components. Littler machine can deliver exceptionally exact plastic parts for surgical applications.

In expansion, numerous sorts of plastic tar’s and additive substances have utilization in the infusion molding process, expanding its adaptability for creators as well as engineers. Additionally, infusion molds, which have ordinarily made from aluminum or steel, have high expenses.

What is the difference between a die and a mold?

Molds, as well as dies, are devices that are fundamental to mass production nowadays fabricating. Nowadays strategies are capable of forming micro order accuracy molds as well as dies, contributing to the mass generation of items with the same shape and quality in a wide run of ranges.

Molds, as well as dies, are both devices for forming. Dies have utilization in forming sheet metals as well as other metal shapes. Also, a commonplace practice is the manufacturing of vehicle body components. On the other hand, molds have utilization in infusion molding like dissolving resin or casting liquid fabric.

How do you know if you have injection mold?

Injection/infusion molding may be a strategy that has utilization in the fabricating of the pliable items. Infusion shaping may be a common fabricating handle that has utilization in making plastic items and fabrics. It includes embedding liquefied plastic into a shape depth that has been planned into the specified shape.

About all, complex 3D plastic parts have infusion shaping.

Which software is best for mold flow design?

XMD delivers mechanization completely coordinates with Key Creator’s energetic modeling devices. The bundle empowers architects to completely show the shape and all required instruments and parts in three-dimensional solids. Custom strong components, as well as plates, can be brought into XMD empowering.

- Automatic detail drawing

- Automatic hole management

- Simultaneous updating of drawing views and

- Automatic hole design as well as

- Automatic interference checking and much more

How much does mold flow software cost?

This item is now easily accessible for up to 10,000$ presently. In past, this item costs about 90,000$. This opens up tall conclusion examination to littler or interment clients who already might as it was born a moderate design recreation program such as Autodesk mold flow consultants.

Additionally, Autodesk Moldflow understanding WS looks and works no diverse from the standard program, but that has a configuration to send coinciding and examination capacities as it were for inaccessible preparing.