Precision Mold for Consumer Products: The Key to High-Quality Manufacturing

Today's quickly evolving consumer goods market depends fully on precision mold technology to deliver durable high-quality products. Through the advent of both injection molding and custom molding, manufacturers can attain exceptional precision levels that benefit their efficiency and minimize production expenses. This article discusses both vital aspects of precision molds for consumer products and their manufacturing approaches and describes how precision mold manufacturers drive product development success.

What Does Daving a Precision Mold Contribute to the Manufacturing of Consumer Products?

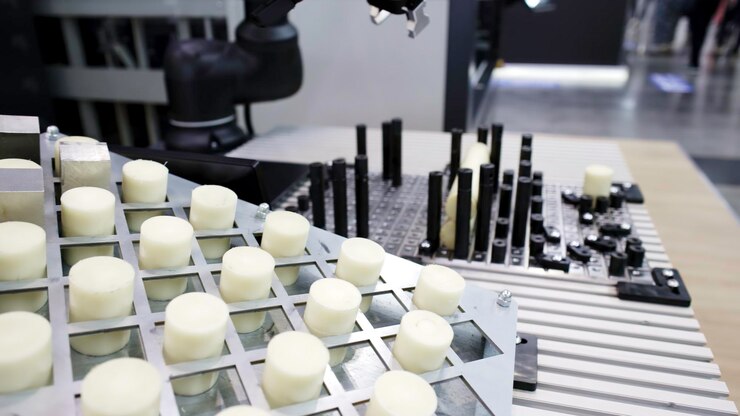

Precision molding uses precise molds to create exact parts of plastic and metal materials that find application in manufactured products for consumers. Accurate molding tools enable precision manufacturing to achieve repeatable high-performance results during production on a large scale. Precision mold manufacturing provides essential service to industries requiring exceptional part quality and appearance for electronics together with medical devices automotive components and household items.

The main business advantages provided by precision mold manufacturing practices include both high precision and specific mold design capabilities.

High Accuracy: The rigorous requirements of technical products such as medical components and electronic parts dictate that precision mold technology enables exact precision for every production piece.

Improved Product Quality: Engineered molds yield functional products that both operate with superior performance and exhibit better design aesthetics as market-driven appeal matters for consumers.

Cost Efficiency: Product precision molds create fewer inferior parts that require disposal and additional intervention thus offering substantial manufacturing cost reductions.

Faster Time-to-Market: Manufacturers benefit from efficient precision molding techniques which allow them to produce large amounts of parts at high speed to shorten product development times.

Types of Precision Molding Techniques

Precision moldmaking boasts different molding techniques that function under its strategic domain. Various molding techniques deliver specialized advantages depending on the consumer product nature. A review of the primary precision molding techniques that actively produce products at present will follow.

Precision Injection Molding

Precise injection molding operates as one of the most frequently employed molding solutions. During this technique, plastic material passes through an injection process at high pressure into generated molds until it entirely fills the cavity shape. Manufacturers achieve precise engineering through mold compositions which enable the production of intricate high tolerance designs.

Applications: Through these methods, manufacturers produce petite customized components that serve the electronics industry and vehicle industry while also enabling plastic packaging solutions.

Advantages: This manufacturing method delivers both precise repetition along economical large-scale production capability and facilitates the creation of intricate component designs.

Two-Shot Molding

When performing two-shot molding practitioners add distinct materials to a mold during sequential injection operations. The technique finds application when manufacturing parts requiring combined functional elements and component materials, especially in electronic enclosure production for soft-touch integrations.

Applications: Manufacturing technologies produce multiple-material products including smartphone cases with rubberized edges and automotive parts that integrate rubber seals into their structure.

Advantages: A single production method enables manufacturers to build multi-material assemblies thus eliminating subsequent operations.

Overmolding

An existing part receives a second material injection through over-molding techniques. Manufacturers perform this process to maximize both appearance factors and usability features in addition to physical comfort attributes in their products. The over-molding process enables manufacturers to fuse hard and soft components together for designing ergonomic consumer product grips.

Applications: Consumer electronics, power tools, medical devices, and toys.

Advantages: Manufacturers use this process to create products that display both durability comfort and visual attractiveness while eliminating manual assembly requirements.

The Role of Precision Molds in Consumer Goods Manufacturing

Precise mold manufacturing stands as an essential requirement to achieve superior manufacturing standards in consumer products. Mold accuracy together with quality directly determines product functionality as well as product lifespan when producing electronic products or automotive components and cosmetic packaging.

The accuracy requirements of consumer goods production demand precision mold manufacturing because minor unpredictability in the mold's dimensions generates defects that break product performance specifications. The production process of medical devices applies precise molds to components such as syringes as well as IV connectors and diagnostic tools to achieve both proper functionality and regulatory compliance.

Consumer products including household goods and toys benefit from precision molds because they produce superior appearance and user experience with extended product durability. By nature, over-molding can manufacture kitchen tools with secure gripping surfaces, and insert molding enables plastic toys to receive stronger metal element components.

Why Choose Precision Mold Manufacturers for Consumer Products?

Consumer goods required for successful mass production depend on obtaining professional mold manufacturing services that deliver precise results. Your partnership with expert custom precision mold manufacturers guarantees quality-standard conformity and efficient manufacturing while enabling large-scale output for your products.

When Choosing a Mold Manufacturer, Consider the Following:

Expertise in Your Industry: Select manufacturers that specialize in your concrete product sector which could include electronics devices medical devices and household item manufacturing.

Advanced Technology: High-precision injection molding and micro-molding technologies from the best manufacturers serve to fulfill your precise requirements.

Proven Track Record: Strong portfolios and excellent client feedback from manufacturers indicate their record of making constant and excellent quality deliveries. Therefore select a manufacturer who demonstrates this duality.

Ace Mold operates a custom molding service dedicated to different sectors which includes both consumer electronics and medical devices while providing superior precision across entire manufacturing projects.

Conclusion

Precision molds are at the heart of consumer goods manufacturing, providing the accuracy and efficiency needed to produce high-quality products. Whether you need custom precision molds for plastic consumer goods or advanced precision molding for electronics, understanding the different types of molding techniques and selecting the right manufacturer is key to achieving your desired results. By choosing a reputable precision mold manufacturer like ACE, you can ensure that your products are built to last, perform well, and meet market demands efficiently.