Custom Online Mold And Molding Service

with Experienced production team and World-class mold and molding production equipment to ensure your project success. Dedicated person tracks project progress. Mold and molding parts 100% Meets size and assembly requirements

- No MOQ

- Tight Tolerance of 0.01mm

- 24/7 Engineering Support

- 25 years of mold manufacturing experience

Custom injection mold and molding service

Our Custom Injection Molding Services

30T-1500T

OPC

0.01mm

2 weeks

ACE Customs Plastic Injection Mold and Molding Services

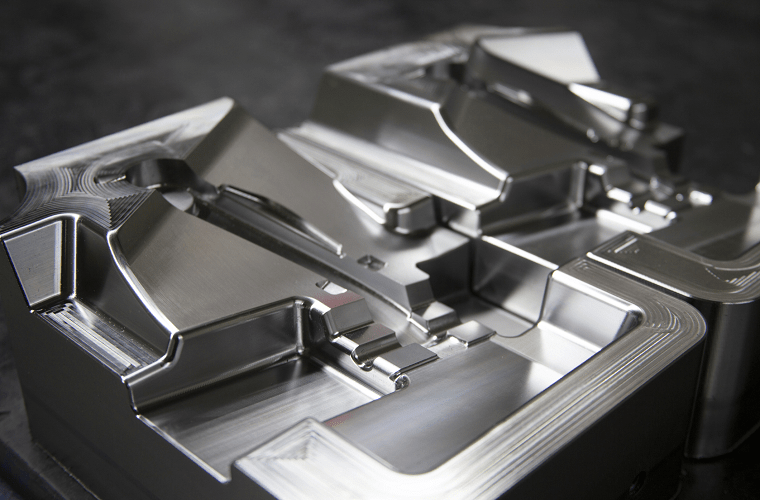

Ace is One of the top high precision mold and molding factory base here in China. We are able to develop new product from Customer idea to actual part. We are able to make buit various types of injection mold and molding, such as, industial engineering material mold,double injection mold,mutil cavities mold, double injection mold, insert and overmolding,gas-assisted injection mold, Mucell mold, IML AND IMD mold,

Custom Injection Molded Products by Ace-mold

Explore the plastic prototypes and custom production parts we’ve crafted for our clients, available for on-demand orders.

What to Get From Online Injection Molding Services

Gaining insights into the injection molding process equips designers and engineers with the knowledge to develop parts optimized for production, leading to cost savings and enhanced quality. Our ebook provides useful guidelines and advice for achieving superior and long-lasting injection molded components.

High Efficiency and Productivity

Precision and Consistency

Versatility in Materials and Colors

Cost-Effectiveness for Large Volumes

Automated Process

Custom Injection Molding Solutions

Discover our injection molding services available on-demand, designed to effortlessly guide you from the prototyping phase to high-quality production

Rapid Prototyping

Take advantage of our swift injection molding services, capable of producing 1,000 to 100,000 units efficiently and cost-effectively. Utilizing aluminum or steel molds, we guarantee quick turnaround times, effectively tackling your production needs and minimizing your product's time-to-market.

Low Volume Production

Our low volume injection molding service enhances your production capabilities, offering the manufacture of 100,000 to 1 million units using durable steel molds. This approach guarantees both high quality and uniformity, perfectly meeting your requirements for substantial yet accurate production batches, all while upholding superior quality standards.

Our Injection Molding for Various Industrial Applications

ACE provides a selection of standard metals for injection molding tooling, along with an array of widely-used plastic materials

- Injection Mold Tooling Materials

- Thermoplastic

- Thermoset

Injection Mold Tooling Materials

A variety of thermoset materials are available for diverse applications, each selected for their distinct bonding properties to suit specific needs.

- Tool Steel: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

- Stainless Steel: 420, NAK80, S136, 316L, 316, 301, 303, 304

- Aluminum: 6061, 5052, 7075

Thermoplastic

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

- ABS HDPE LDPE PP

- PPA PS POM PC

- PU Teflon (PTFE) Nylon

- PC PMMA PA PEEK

- PET

Thermoset

We offer a range of thermoset materials, each suited for different applications thanks to their specialized bonding characteristics.

- Liquid Silicone Rubber Epoxy

- Polyurethane Phenolic

Note: You can learn more from our eBook on plastic materials.

Ace Mould Success Case

Our primary focus is on providing SPI finishes for plastic injection molds. If you require VDI textures, please specify your needs when requesting a quote through our online platform.

| Mold Type | Success Project description | Frist Sample Lead Time | Part Tolerance | ||||||||||

| Double injection | We are able to build both vertical double injection, parallel injection ,core rotation double injection mold | 4 weeks | ± 0.01mm | ||||||||||

| Industial plastic mold | With High glass fiber plastic material part, High temperature mold, with Low fluidity plastic material mold | 4 weeks | ± 0.01mm | ||||||||||

| Over mold | Two times injection processing. Can be soft material with hard material or with hard material over mold injection | 3 weeks | ± 0.01mm | ||||||||||

| Insert mold | Terminal insert molding, metal insert molding, and one top two core bottom insert mold, core rotation insert mold | 3 weeks | ± 0.01mm | ||||||||||

| forming mold | Chemical forming mold and thermoforming mold, to reduce the part weight and improve part surface, reduce injection cycle time | 3 weeks | ± 0.01mm | ||||||||||

| Nitrogen mold | Improve the part surface and reduce part weight | 3 weeks | ± 0.01mm | ||||||||||

| IML Mold IMD mold | To protect the high transfer surface can achieve the printing together during injection, save part printing processing | 3 weeks | ± 0.01mm | ||||||||||

| High cavitation mold | Efficient part production, with High production capacity part, successful in over 128 cavities mold | 4 weeks | ± 0.01mm | ||||||||||

| Die casting and Alloy mold | Zinc alloy mold, Aluminum alloy molds, Magnesium alloy mold Investment casting | 3 weeks | ± 0.01mm | ||||||||||

Injection Molding Whitepaper

Gaining knowledge about the injection molding process is crucial for designers and engineers to design parts that are manufacturing-friendly, leading to cost reduction and quality enhancement. Our ebook is a valuable resource, offering practical advice and guidelines for creating exceptional and long-lasting injection molded components.

Injection Molding Capabilities

At Ace Our engineering department will have details study with customer product, and give our best suggestion for the part optimize, meanwhile our engineering department will according to customer request to choose the best and lower cost for the solution, make sure all part in good quality but also spend the lowest money for the project

Injection Mold Surface Finishes 2

We primarily offers SPI finishes for plastic injection molds. For VDI textures, specify your requirements when submitting your quote on our platform.

| Mold Class | Production Level | Cycles | Applications | Tolerance | Cost | Lead Time |

| Class 105 | Very low | Less than 500 cycles | Prototype testing | ± 0.02mm | Inexpensive to produce a very limited number of product prototypes | 7-10 days |

| Class 104 | Low | Less than 100K cycles | Good for limited-production parts with non-abrasive materials | ± 0.02mm | Fall within low to moderate price ranges | 10-15 days |

| Class 103 | Medium

| Less than 500K cycles | For low to medium-production parts | ± 0.02mm | Fall within common price ranges | 10-15 days |

| Class 102 | Medium to high | Less than 1M | Good for parts with abrasive materials and/or tight tolerances | ± 0.02mm | Fairly high price and made with materials of high quality | 10-15 days |

| Class 101 | Extremely high | Over 1M cycles | Extremely high production and fast cycle times | ± 0.02mm | Highest price and made with only the highest quality materials | 10-18 days |

How Custom Injection Molding Works?

In the injection molding process, raw plastic materials are loaded into an injection molding machine, where they are melted. These melted plastics are then injected into a mold made of aluminum or steel. As the material cools, it solidifies into a production-grade thermoplastic part, which is then ejected for subsequent use or assembly.

Injection Molding Process At Ace-mold

Discover how Ace-mold manages your orders, starting from providing quotes, crafting high-quality injection molds, to producing production-grade plastic parts. Our experienced team and advanced machinery ensure each step is completed efficiently for on-time delivery

Request for Quote

After receive the RFQ, our engineering department will have meeting to study the best solution for the quote, we will provide the quotation according to your request, if we can quote, that means we can make the part perfectly, quotation time within 24 hours

DFM Report

We can provide the preliminary during the quotation stage if customer request, after order kick off we will make the details DFM for our customer confirmation.

Mold Flow Analysis

We have our own internal Moldflow team to analysis the part details, we can provide the customer suggestion for part after study the mold flow analysis report.

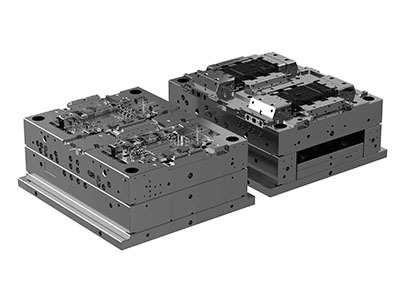

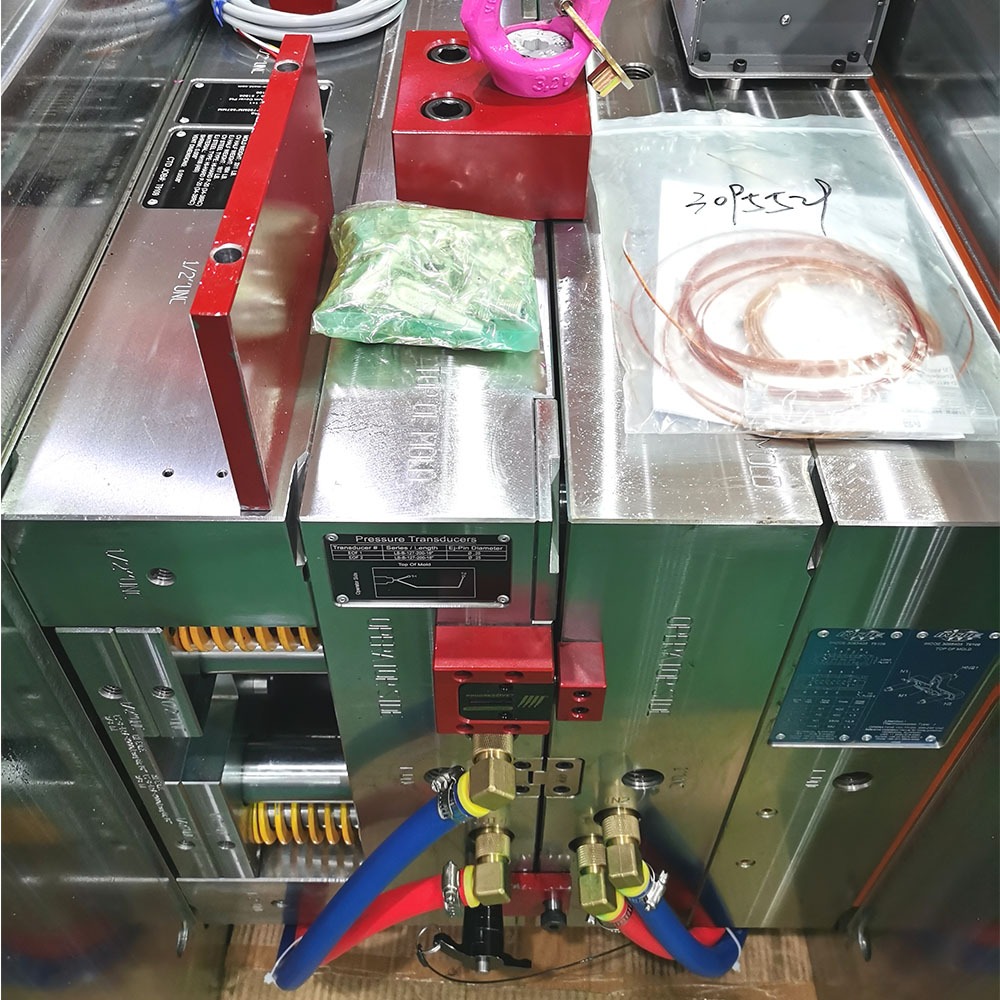

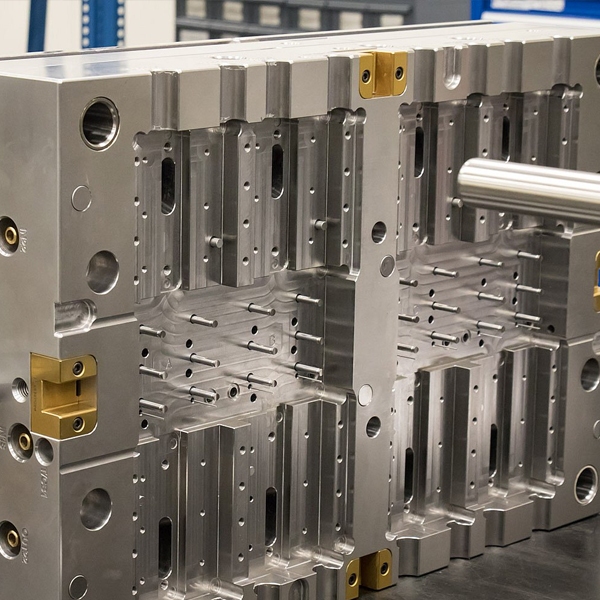

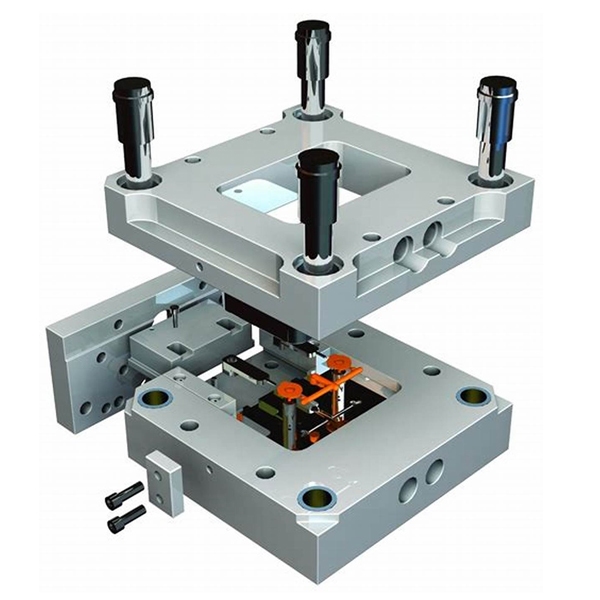

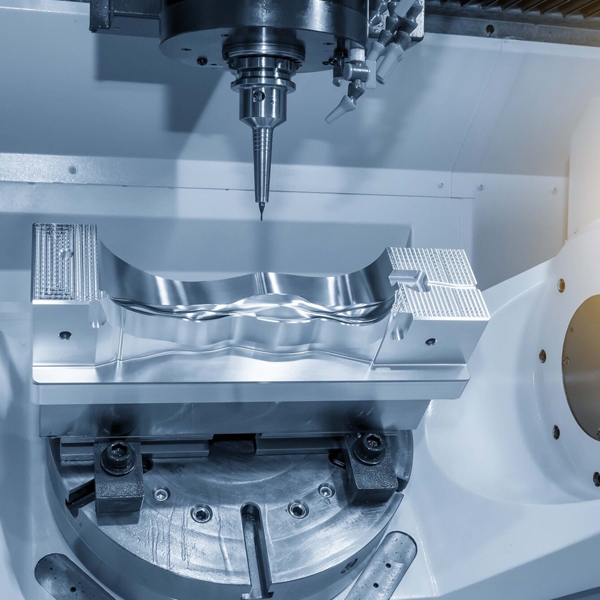

Mold Tooling Production

We will strictly check the components dimension make sure all dimension is correct and we will go ahead with the next production, to make sure all components is in tolerance before mold test

T1 Sample Verification

We will provide the request quantity sample for customer verification, meanwhile we will provide the full dimension report and processing parameter for your reference.

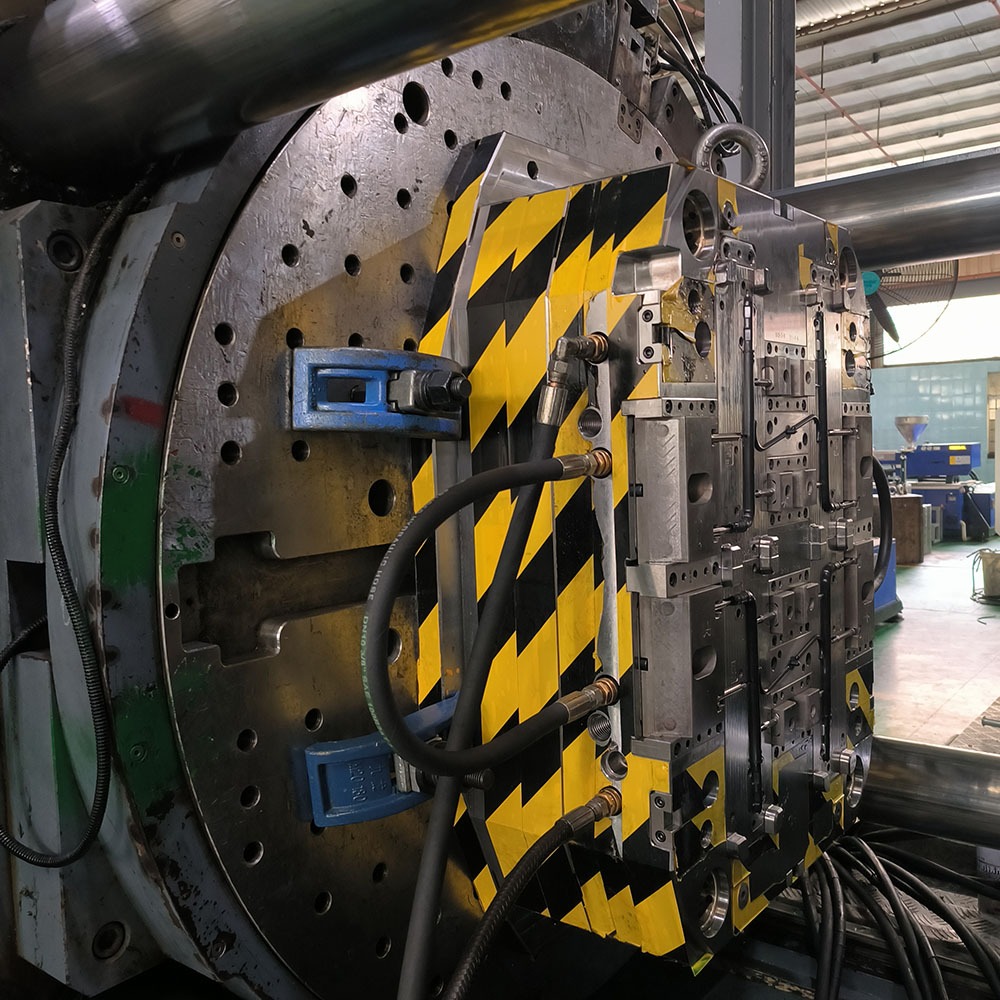

Low Volume Production

We have from 30t to 1200-ton injection machine in house, we can follow the confirmed sample to manufacture the batch of sample for customer.

QC Inspection

We can provide the part CMM and 3D scan service inspection. To strictly follow customer provided tolerance drawing to check the actual part.

Package and delivery

We will provide the different package according to customer transport request, by sea or by air. We will also provide the necessary document to assist our customer make customs clearance.

Our Injection Molding Services Cater to a Range of Industrial Applications

Ace-mold offers tailored injection molding solutions to meet the unique needs of various industries.

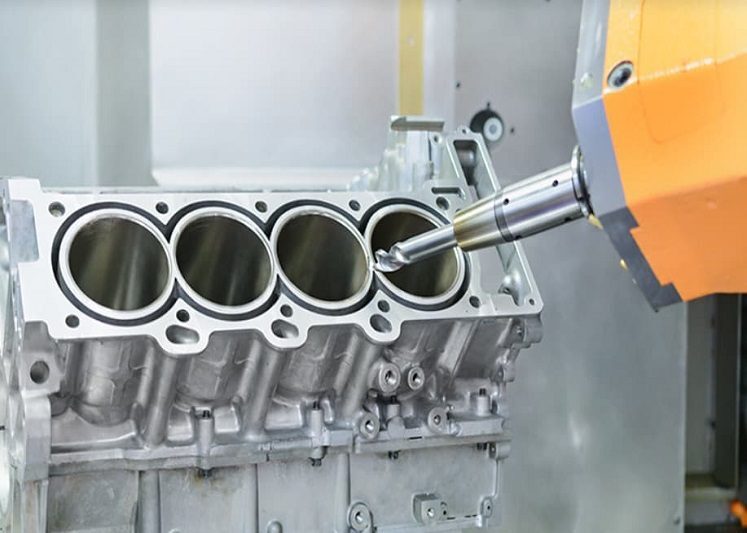

Automotive Industry

Aerospace Industry

Medical Device Industry

Robotics Industry

Reasons to Opt for Our Specialized Custom Injection Molding Services.

No MOQ

Our no minimum order policy facilitates the swift transition of plastic molded parts from design to production with quick turnaround times, catering to your on-demand injection molding requirements while also minimizing costs.

High Quality and Consistency

Possessing ISO certified factories and performing in-process inspections and dimensional verifications post-production, we ensure consistent quality in custom molded parts. This holds true even for complex shapes, as we maintain high precision throughout

Fast Turnaround

Our certified domestic factories and robust supply chain system enable us to expedite the product development cycle, allowing for the rapid production of plastic parts in as little as 2 weeks or even less.

Injection Molding Expertise

Work alongside our specialists, who have over 10 years of experience in injection molding, for expert advice on mold design, material selection, and finishing options, ensuring a seamless shift from prototyping to full-scale production.

Plastic injection molding is a service that involves the manufacturing of plastic parts using a molding process. Here’s an overview of what this service typically includes:

- Design and Engineering: The process usually begins with the design and engineering phase, where the specific requirements of the plastic part are determined. This includes its size, shape, complexity, and the type of plastic material to be used. CAD software is often used to create a precise design.

- Mold Making: Once the design is finalized, a mold is created. The mold is a crucial part of the injection molding process, as it shapes the final plastic product. Molds are typically made from steel or aluminum and are precision-machined to match the design specifications.

- Material Selection: The appropriate plastic material is selected based on the part’s application, durability requirements, and other factors like temperature resistance, strength, and flexibility. Common materials used include ABS, polycarbonate, polyethylene, and nylon.

- Injection Molding Process: In this step, plastic pellets are fed into an injection molding machine where they are melted. The molten plastic is then injected under pressure into the mold. Once the plastic cools and solidifies, it takes the shape of the mold.

- Cooling and Ejection: After injection, the plastic part needs to cool and solidify. Once it’s solid, the part is ejected from the mold. The mold can then be used again for the next cycle.

- Post-processing: After ejection, the parts may undergo various post-processing steps like trimming of excess material, polishing, or painting. These steps depend on the specific requirements of the part.

- Quality Control: Throughout the process, quality control measures are taken to ensure that the parts meet the required specifications. This includes checks for dimensions, material properties, and overall appearance.

- Assembly and Packaging: If required, parts can be assembled with other components. Finally, the parts are packaged and prepared for shipping.