What Makes A Prototype Tool Crucial for Injection Molding Process?

A plastic molding prototype tool can define a production process's success or failure before the process even begins. It does not predict but physically visualizes the end product specifications, geometric features, and performance characteristics. Therefore, it saves time, investment, and efforts.

A plastic molding prototype tool is one of the most promising methods of plastic molding prototyping. It is highly preferred by commercial molders worldwide because of the information it helps gather.

You May Also Read: A 2020 Guide to Electric Plastic Injection Molding Machine

This article sheds light on the importance that a prototype tool holds in the commercial-scale plastic molding process. But first, we will explain the process of plastic injection molding and introduce the prototype tool that this article revolves around

What is Injection Molding?

The plastics manufacturing industry employ the injection moulding process where they call it plastic injection molding.

The plastic injection molding process has been around for ages. It is not going anywhere anytime soon because of its capability of mass-producing plastic parts in a short period.

This process uses plastic resins as raw material. It has coil-heaters that melt these resins and employs a screw-type plunger that pushes the molten plastic into the molds. This molten plastic solidifies in the mold before it opens, and the ejector pins push the solidified, molded plastic part out.

The plastic molding process can be optimized for high accuracy and repeatability to ensure part specification consistency and minimize defects in molded products.

Since the mold defines the end product's quality. It must be made just right to curate a plastic part that aligns perfectly with the given end-product specifications.

This is where a prototype tool for plastic molding comes in.

What is a Prototype Tool for Plastic Molding?

Plastic molding is a tightly controlled process. Even a second's delay in cycle time can reflect in the molders' revenue as reduced profit. Therefore, to mitigate all possible problems expected in the product's design, specifications, performance or manufacturing process, prototyping is imperative.

Hence, most molders opt for creating a product prototype to test its performance and specifications. And fine-tune their production process, system variables and raw material accordingly.

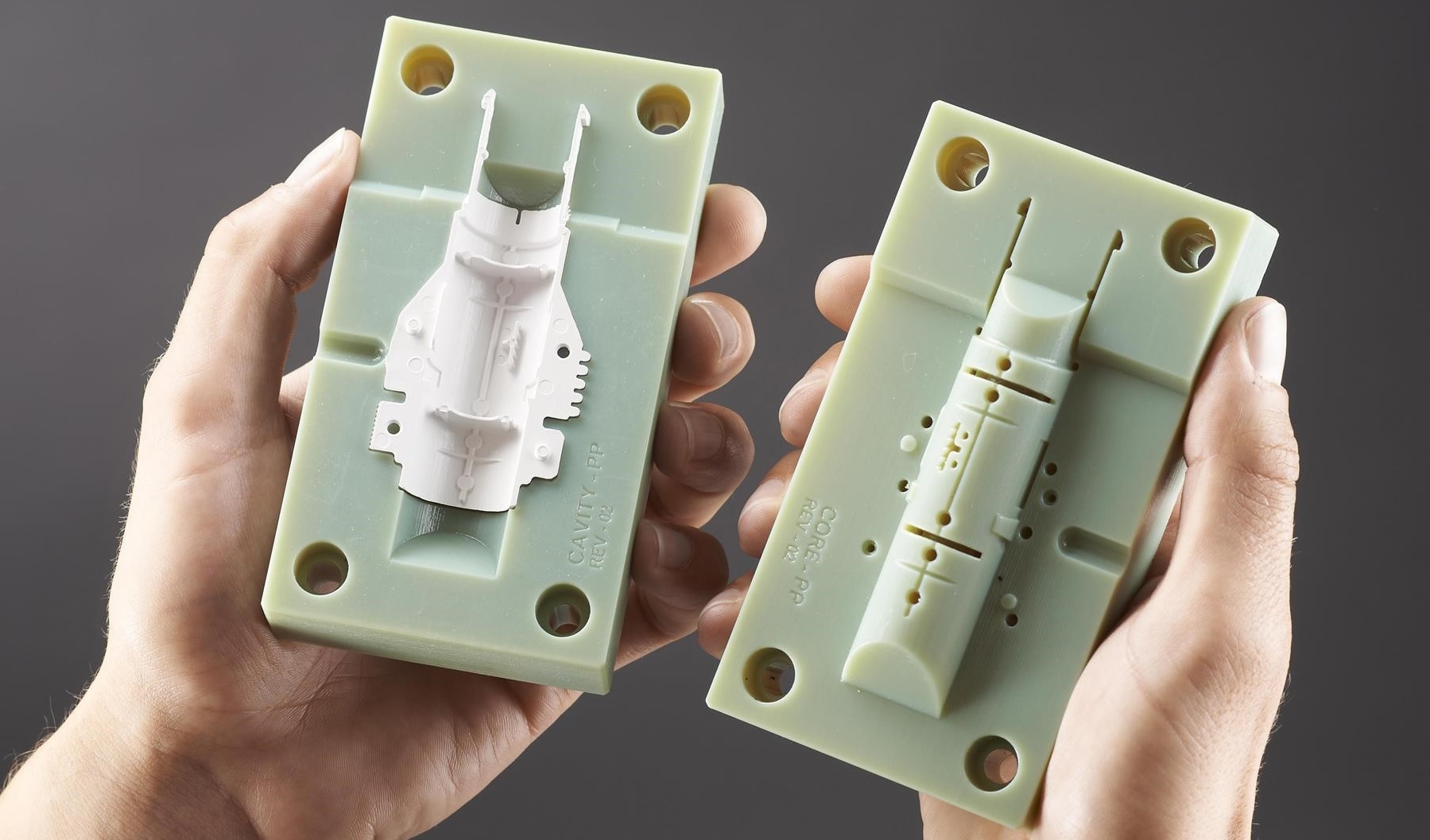

To create these prototypes that represent the end product, commercial molders prefer using a prototype tool. A prototype tool is a specially designed prototype mold that is usually made out of aluminium.

This prototype tool serves on a small scale plastic molding machine and molds samples of the end products. The design engineers and molders inspect these samples and take decisions regarding the actual production process.

The plastic molding prototype tool is vital in determining whether a set of system parameters are suitable for any given process or not. Thus, we cannot overstate the importance of a prototype tool for the success of a plastic molding process.

Importance of Prototype Tool in Plastic Injection Molding

The injection molding process is a hefty investment. Molders cannot afford hit and trials when it comes to producing injection-moulded parts. Therefore, it is crucial for them to mass-produced good quality products in one go.

A Prototype tool eliminates iterations from the injection molding process. Following are some of the contributions of a prototype tool that make it an essential part of the injection molding pre-production process.

Gaining Investors- Introducing Concepts

Injection molding is a process that needs investment because the manufacturing process of each new product requires a whole new mold. And molds don't come cheap. Therefore, molders, especially those just starting, need investors.

No matter how great the idea is, investors might never accept it if one does not present it properly. Injection molding prototype tools help convert a concept into a physical product. The potential investors can inspect this sample and then decide on investing in the project.

Using a prototype tool, molders can create prototypes of end products to present to the potential investors. A prototype tool can mold plastic parts as per the required specifications. If something goes wrong, designers can easily modify these tools to mitigate the issues. And mold great looking and performing samples of the product.

Market Research

Market research is a critical pre-production procedure that determines whether investing in a particular product's production will be profitable.

An injection molding prototype tool serves to create samples of the intended product and sent to the customers for trials. If the customers approve of the product, then bulk production can begin. Thus, it saves molders from spending on raw material and investing in bulk production of products that risk rejection.

Moreover, if the users disapprove of the prototype tool's sample, one can easily modify the tool to accommodate customer feedback and mold new prototypes accordingly.

In this way, prototype tools help commercial injection molders perform a market survey with a product prototype and predict their products' value before the commencement of bulk production.

Product Performance

Many plastic products need to perform in electronic gadgets and devices, cars, and other machinery. And for such applications, manufacturers must test them for their performance before being commissioned for use.

Testing products after production in bulk is extremely risky. If the results are not as expected, the products will waste and take all the money and raw material invested with them.

Therefore, injection molders prefer testing their plastic products for performance by molding prototypes of the products using a prototype tool for injection molding.

In this way, the manufacturers can spot discrepancies in the pre-production stage and eliminate them before the concept goes into production.

End Product Aesthetics

Not all products are injection-molded for monotonous and dull applications like in automobiles and machinery. Some parts serve to please the user aesthetically like mobile phone covers, jewellery decoration pieces, kitchen décor etc.

For such aesthetic applications, molders need to ensure that the molded part will look good in the material and pigment they have chosen. Again, to test their ideas, they opt for prototyping their products using prototype tools.

These prototype tools create product samples in the right shape, size and colour. Moreover, if they fail to produce the product's required specifications, designers can alter their attributes and resolve the underlying issues.

Part Geometry

The part geometry is another very sensitive aspect of the plastic-molded product. When molded, the plastic is hot and soft and not taking necessary steps can lead to defects in the end product and a loss in terms of profit.

An injection molding prototype tool allows molders to check if the design parameters and mold design are accurate to ensure no geometric defects in the end products.

Thus, along with helping to gain investors and market research, the prototype tool also minimizes operation cost and raw material waste by eliminating possible product defects.

Reduces Production Time

A prototype tool for injection molding helps molding samples or prototypes of the end-product, minimizing the probability of defects in the products and problems in the molding process.

In this way, this tool reduces the overall production time by helping the design engineers eliminate all possible issues in the pre-production stage. And a minimized production time translates into increased profit.

You May Also Read: A Complete Guide to Precision Molded Plastic

Conclusion

An injection molding prototype tool is the design engineers' best friend. It helps them locate issues with the design parameters and in the product specifications before the production begins. To eliminate these problems before the product goes for mass-production and enhance the efficiency of their process.

The prototype tooling is one of injection molding prototyping methods. Some other techniques for creating prototypes include SLS, SLA, FDM and CNC machining.

However, creating plastic samples with prototype tool proves to be the most efficient because it molds samples similar to the end product and thus helps generate authentic market research and product performance data.

For More Information, Contact Us Today!