In the world of manufacturing, injection molding has emerged as a game-changer, enabling the production of complex and precise plastic components at scale. Among the leading pioneers in this field is the ACE Injection Moulding Company. With its cutting-edge technology and expertise, ACE has established itself as a trusted manufacturer, delivering high-quality injection molds for various industries.

I. Understanding Injection Molding

1.1 What is Injection Molding?

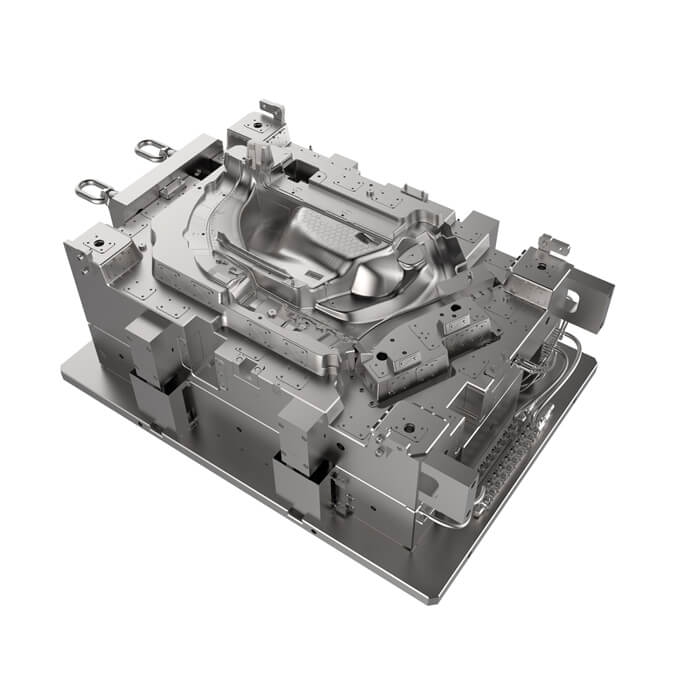

Injection molding is a manufacturing process used to produce a wide range of plastic parts and products. It involves injecting molten plastic material into a pre-designed mold cavity, allowing it to cool and solidify, resulting in the desired shape. Injection molding offers exceptional precision, repeatability, and scalability, making it the go-to choice for manufacturing intricate components.

1.2 The Advantages of Injection Molding

Injection molding offers several advantages over traditional manufacturing methods, such as:

a) Cost Efficiency: With the ability to produce large quantities of parts in a single production run, injection molding significantly reduces per-unit costs.

b) Design Flexibility: The process accommodates complex geometries, intricate details, and varying wall thicknesses, giving designers the freedom to create innovative products.

c) High Precision: Injection molding offers exceptional accuracy and tight tolerances, ensuring consistency in part dimensions and quality.

II. ACE Injection Moulding Company: Leading the Way

2.1 Advanced Manufacturing Facilities

ACE Injection Moulding Company boasts state-of-the-art manufacturing facilities equipped with cutting-edge injection molding machines and technology. These machines are capable of handling various thermoplastic materials and are computer-controlled for precise control over the injection process.

2.2 Expertise and Experience

With years of experience in the field, ACE Injection Moulding Company has developed a team of highly skilled engineers and technicians who possess deep knowledge of injection molding techniques. Their expertise allows them to provide comprehensive design assistance, optimize mold design, and ensure efficient production processes.

2.3 Customization and Innovation

ACE Injection Moulding Company takes pride in its ability to meet diverse customer requirements. From initial design concept to final product delivery, ACE collaborates closely with clients, providing tailored solutions that meet their specific needs. The company's commitment to innovation ensures that they stay at the forefront of technological advancements in the injection molding industry.

III. Applications of Injection Molding

3.1 Automotive Industry

The automotive sector extensively relies on injection molding for the production of various components such as dashboards, bumpers, interior trims, and more. ACE Injection Moulding Company has established strong partnerships with leading automotive manufacturers, delivering high-quality molds that meet the stringent requirements of this industry.

3.2 Consumer Electronics

In the consumer electronics industry, injection molding plays a crucial role in manufacturing components like casings, buttons, connectors, and housings. ACE Injection Moulding Company's precision molding capabilities and attention to detail ensure the production of top-notch molds for electronics companies, enabling sleek and durable product designs.

3.3 Medical and Healthcare

Injection molding is widely used in the medical and healthcare sectors for the production of items such as syringes, medical device components, and packaging. ACE Injection Moulding Company adheres to strict quality standards and regulatory requirements, ensuring the safety and reliability of molds used in this critical field.

Ⅳ. How to Buy the Best Injection Mold for Your Projects?

In the world of manufacturing, injection molding plays a crucial role in producing high-quality plastic parts and components. Whether you are a seasoned professional or a novice in the industry, finding the right injection mold for your projects is vital for achieving success. As a trusted manufacturer, ACE Injection Moulding Company provides valuable insights and expertise on this topic.

4.1 Understanding Your Project Requirements:

Before embarking on the journey of purchasing an injection mold, it is essential to have a clear understanding of your project requirements. Consider factors such as the type of plastic material, desired product dimensions, production volume, and expected product lifespan. Defining these requirements will enable you to communicate effectively with the mold manufacturer, ensuring that they can meet your specific needs.

4.2 Choosing a Reliable Mold Manufacturer:

The success of your injection molding project greatly depends on the quality of the mold you select. Therefore, it is crucial to choose a reliable mold manufacturer. ACE Injection Moulding Company, known for its expertise and commitment to quality, is an excellent choice. Conduct thorough research on the manufacturer's reputation, experience, certifications, and customer reviews to gain confidence in their ability to deliver a high-quality mold.

4.3 Collaborating with the Manufacturer:

Once you have chosen a reliable mold manufacturer like ACE Injection Moulding Company, it is essential to establish a collaborative relationship with them. Engage in open communication, providing detailed information about your project requirements, timeline, and budget constraints. A reputable manufacturer will work closely with you, offering valuable suggestions and technical expertise to optimize the design and functionality of your injection mold.

4.4 Understanding Mold Design and Materials:

To ensure the best results for your injection molding project, it is crucial to understand the basics of mold design and materials. The design of the mold should consider factors such as the type of plastic material, gating system, cooling channels, and ejection mechanism. The choice of mold materials, such as steel or aluminum, should be based on factors like production volume, product complexity, and expected lifespan. Seek advice from the mold manufacturer to make informed decisions regarding mold design and materials.

4.5 Quality Assurance and Testing:

A reputable mold manufacturer like ACE Injection Moulding Company will prioritize quality assurance and testing. Ensure that the manufacturer has a robust quality control process in place to guarantee the mold's precision and durability. The mold should undergo rigorous testing to identify and rectify any potential issues before it goes into production. This will help minimize defects, reduce production downtime, and ensure a smooth manufacturing process.

4.6 Considering Long-Term Support:

When purchasing an injection mold, it is crucial to consider the long-term support provided by the manufacturer. Find out if they offer maintenance, repair, and spare parts services. A reliable manufacturer should be able to provide ongoing support to address any issues that may arise during the lifespan of the mold. This will help extend the mold's life and optimize its performance, ultimately saving you time and money in the long run.

Conclusion

As injection molding continues to reshape the manufacturing landscape, the ACE Injection Moulding Company stands at the forefront of this technological revolution. With their advanced facilities, expertise, and commitment to customization, ACE delivers innovative and high-quality molds for diverse industries. By harnessing the power of injection molding, manufacturers can unlock new possibilities, streamline production processes, and bring their visionary designs to life.