What is injection molding?

Injection molding is a fabricating handle that has utilization in the creation of parts by infusing liquid fabric into a form. It can be done with a lot of materials primarily counting metals for which the method is known as die cutting, confections, and glasses, as well as elastomers, and foremost generally thermosetting as well as thermoplastic polymers.

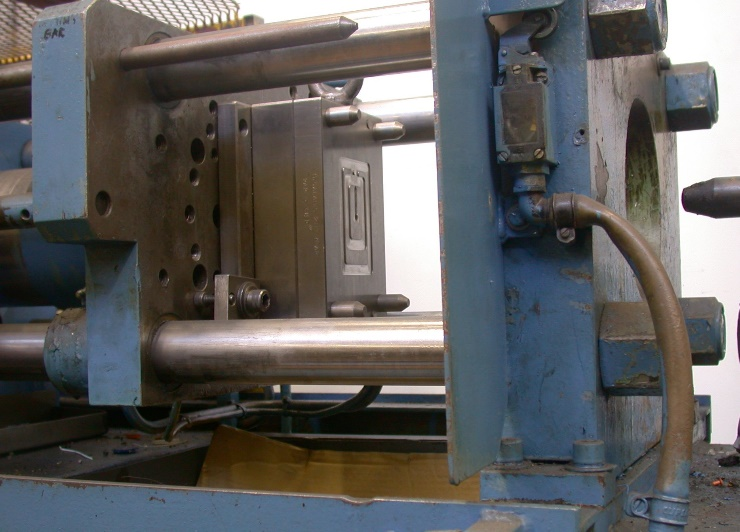

Injection molder has great utilization in injection molding.

Material for the portion has nourishment into a warm barrel, blend by employing a helical screw, and infusing into a shape depression, where it chills and solidifies to the setup of the cavity. Progress in three-dimensional printing innovation, utilizing photopolymers that don’t dissolve amid the infusion shaping of a few lower warmth thermoplastics, have utilization for a few straightforward infusion molds.

What is the principle of injection molding?

The working guideline of the injection/infusion molding machine is comparable to the syringe that has utilization for infusion. It employments the pushed of the screw to infuse the moldable plastic within the liquid state that’s the thick fluid state into the close shape depression. The method of getting items after forming as well as curing.

Injection molding could be a cyclic handle, each cycle primarily incorporates:

- Quantitative feeding dissolving

- Moldable pressure infusion filling and

- Cooling form opening as well as taking parts

What is the injection molding technique?

Infusion molding may be a strategy to get molded items by infusing plastic fabrics dissolved by warm into a shape, and after that chilling as well as setting them. The strategy is appropriate for the mass production of items with complex shapes, also takes a huge portion within the zone of plastic processing.

Injection molders have utilization in molding the material according to the shape desire.

What is an injection molding machine?

An injection molder or an infusion molding machine may be a machine for the fabrication of plastic items by the infusion molding method. It comprises two primary parts; a clamping unit and an infusion unit. It can be affixed in either an even or vertical position. The lion’s share of a machine has a level plane arrangement.

On the other hand, the vertical machine has utilization in a few specialty practices like embed molding, permitting the machine to require the benefit of gravity. Moreover, some vertical machines do not require mold fastening. The attractive and water power clamps have utilization where it is need of quick device changes.

What are the types of injection molding?

Injection molders have classification primarily by the type of driving systems they utilizing. Here are the six types of injection molding technologies.

What is thin wall molding?

Lean driver molding is an infusion molding innovation that accomplishes a plastic portion with a lean driver. It has frequent utilization in test devices, gadgets, vessels, and tubes, along with other enclosures.

Plastic molders who do thin divider molding got to consider each angle of the portion plan, and shape plan, as well as handling in detail to guarantee than the lean driver geometry, will hold up without quality issues.

What is gas-assisted injection molding?

The inconvenience with any thick plastic injection molding portion is that it goes with the chance of mutilation because it cools. Gas-assisted infusion molding makes a difference fathom this issue by shooting gas into a plastic fabric-filled infusion shape.

This permits the plastic on the exterior of the shape to preserve a smooth as well as wrapped up appearance. Whereas the interior remains permeable or empty. This is not as it kept the portion from misshaping amid the cooling organize. But too reduces the expense of the portion as you’re utilizing less fabric.

What is metal injection molding?

Plastic is not the as it were the thing that can infusion molded, also metals can as well. This modern innovation is significantly more costly than plastic infusion molding and ordinarily serves as a specialty showcase. The cell phone showcase, for illustration, now and then employments metal infusion molding to shield the cellular gadgets from radio or maybe a microwave.

What is liquid silicon injection molding?

The lion’s share of plastic infusion molding is thermoset, meaning the chill fabric has infusion to an amazingly hot form to make a portion. This handle cures the portion so it cannot dissolve once more. But if you wish a portion to resist exceptionally tall temperature or certain restorative gadgets or car parts.

You may require thermoplastic infusion molding, which as often as employments fluid silicone.

What is 3D printing?

Three-dimensional printing could be an imminent infusion of molding innovation since of the part it plays in prototyping.

What are unique material formulations?

Whereas this is not a plastic infusion “strategy” within the conventional sense, utilize one of kind fabric definitions does progress molding capabilities. Infusion molding companies may, for case, utilize a carbon or mineral filter, a blowing specialist. And a lubricity added substance to include certain characteristics to a portion.

What is the injection molding process?

The method cycle for infusion molding is exceptionally brief, regularly between 2 seconds to 2 minutes, and comprises the taking after stages:

What is clamping?

Earlier to the infusion of the fabric into the form, the two parts of the form must begin with the safe closing of the clamping unit. Each part of the form has a connection to the infusion molding and the other half has permission to slide. The time needs to shut and clamp the shape is subordinate to the machine. This time has evacuation from the dry cycle time of the machine.

What is the injection of the material?

The crude plastic fabric, as a rule within the frame of pellets, is bolstered into the injection molder. Amid the method, the fabric softens by warmth and weight. The liquid plastic is at that point infused into the shape exceptionally rapidly and the buildup packs as well as holds the fabric.

The infusion time is troublesome to count precisely due complicated and varying stream of the liquid plastic into the form.

What is the cooling of the material? - Injection Molder

The liquid plastic that’s interior the form starts to cool as before as long it creates a link with the interior form surfaces. The pressing of fabric within the infusion organize permits the extra fabric to flow into the shape and decrease the sum of unmistakable shrinkage.

The cooling time can be evacuated from a few thermodynamic characteristics of the plastic and the greatest divider thickness of the portion.

What is the ejection of the material?

After passing adequate time, the cool portion may be shot out from the shape by the launch framework. Constrain must have a connection to the portion since amid cooling the portion shrivels and follows the shape.

What is an injection molded used for?

Injection molder has utilization in the creation of numerous things that have utilization in our daily life. Such as car parts, bottle caps, toys, stash comb and melodic rebellious, and much more plastic items.