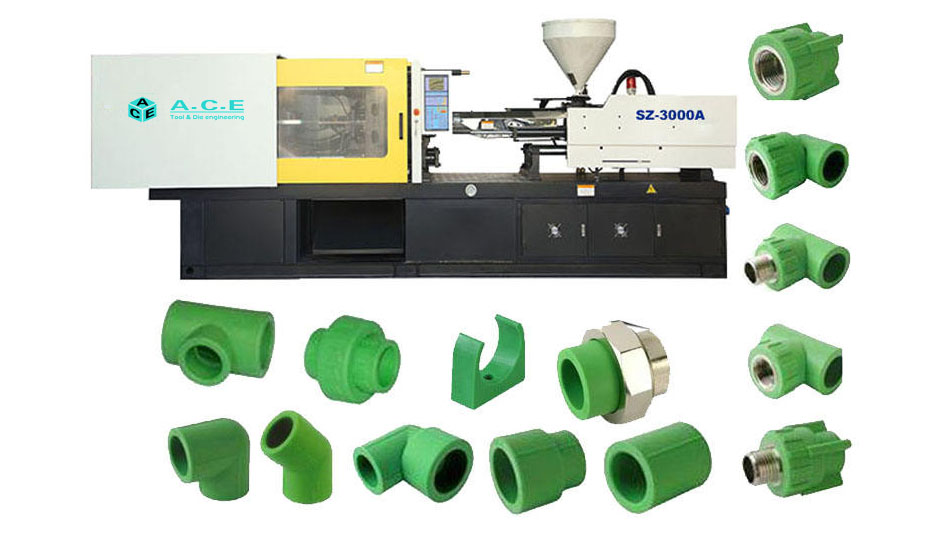

Injection molding machines consist of several parts, including the hopper, screw, barrel, clamping unit, injection nozzle, and control panel.

- Hopper: This is where plastic pellets are stored before being fed into the machine.

- Screw: The screw is responsible for transporting the plastic pellets from the hopper to the barrel, where it is heated and melted.

- Barrel: The barrel is where the plastic is heated and melted.

- Clamping Unit: The clamping unit holds the mold in place and applies pressure to the molten plastic to form the desired shape.

- Injection Nozzle: The injection nozzle injects the melted plastic into the mold.

- Control Panel: The control panel is used to operate the machine and set parameters such as temperature and injection time.

Other parts such as the hydraulic system, electrical system, and cooling system also play important roles in the operation of the machine.

Injection moulding is one of the most popular manufacturing processes used in the modern world. It is used to create a wide variety of products, from automotive components to medical devices. In order to ensure that these products are made to a high standard, it is important to use the right injection moulding machine parts. In this article, we will discuss three tips for buying high-quality injection moulding machine parts.

Introduction to Injection Moulding Machine Parts

Injection moulding is a process in which molten plastic or other materials are injected into a mould to form a desired shape. The material is heated and injected under pressure into a mould, which is then cooled and released. The injection moulding process is used to create parts of all shapes and sizes, from small toys to large automotive parts.

In order to ensure that the injection moulding process is successful, it is important to use the right injection moulding machine parts. These parts can include moulds, injection units, hoppers, sprue bushings, and more. The quality of these parts can have a huge impact on the quality of the final product.

What to Look for When Buying Injection Moulding Machine Parts

When it comes to buying injection moulding machine parts, there are a few things to consider. These include quality, price, and compatibility.

Quality

Quality is the most important factor when it comes to buying injection moulding machine parts. Poor quality parts can lead to a range of problems, from poor product quality to costly downtime. It is important to make sure that the parts you are buying are made to a high standard. Look for parts that are made from durable materials and are designed to last.

Price

Price is also an important factor to consider when buying injection moulding machine parts. The cost of the parts can have a big impact on the overall cost of the project, so it is important to make sure that the parts you are buying are reasonably priced. Look for parts that are competitively priced and offer good value for money.

Compatibility

It is important to make sure that the injection moulding machine parts you are buying are compatible with your moulding machine. Different machines have different requirements, so it is important to make sure that the parts you are buying are suitable for your specific machine. Check the manufacturer’s specifications to make sure that the parts are compatible.

Tips for Buying High-Quality Injection Moulding Machine Parts

Now that we have discussed the factors to consider when buying injection moulding machine parts, let’s look at some tips for buying high-quality parts.

Research the Manufacturer

The first tip is to research the manufacturer. It is important to make sure that you are buying parts from a reputable manufacturer. Look for manufacturers that have a good reputation and a proven track record of producing high-quality parts. You should also look for manufacturers that offer good customer service and are willing to stand behind their products.

Ask for References

Another tip is to ask for references. Ask the manufacturer for references from customers who have used their products. This will help you to get an idea of the quality of their products and the level of customer service they provide.

Consider the Warranty

Finally, it is important to consider the warranty. Look for manufacturers that offer good warranties on their products. This will help to protect you in the event that something goes wrong with the parts you have purchased.

Conclusion

In conclusion, buying high-quality injection moulding machine parts is essential for ensuring that your products are made to a high standard. There are a few things to consider when buying injection moulding machine parts, such as quality, price, and compatibility. Furthermore, there are a few tips for buying high-quality parts, such as researching the manufacturer, asking for references, and considering the warranty. By following these tips, you can ensure that you are buying the best parts for your injection moulding machine.