Key points in China Plastic Molding Manufacturing

China Plastic Molding is a cheap yet most used technology in the manufacturing industry. Molding is a very old technique. You can often see that the term molding comes in sight whenever you mention plastic.

Earlier the mold quality did not matter at all. But keep in mind, the current demand in China Plastic Molding there is a rapidly increasing trend. This trend has coerced the manufacturers to look for different and effective ways to make plastic molds. The mold quality is improving as well as the awareness regarding molds. The manufacturers are totally keeping a check on their mold quality to walk hand in hand with the consumer’s demands.

You May Also Read: Plastic Injection Molding Companies Introduces the Scientific Mould

For the sole purpose of meeting consumer demands, it has become essential for the China Plastic Molding manufacturers to hereby the changing trends. They have to supervise the design for the molds with a keen eye for quality and purpose assurance. There is a proper check for prerequisites for making the molds.

This ensures that the mold is an exact prototype of what the customer demanded. A mold trial is also conducted for the convenience of the client. The performance of this step is solely for client satisfaction. It actually saves time and cost.

Use of Injection Parameters for China Plastic Molding Manufacturing

Since China Plastic Molding Manufacturing is gaining popularity, so is the trend for developing new ways to make these molds. Researchers are into developing time and cost-saving technologies that can help the manufacturers in optimizing their resources.

What is Injection Molding?

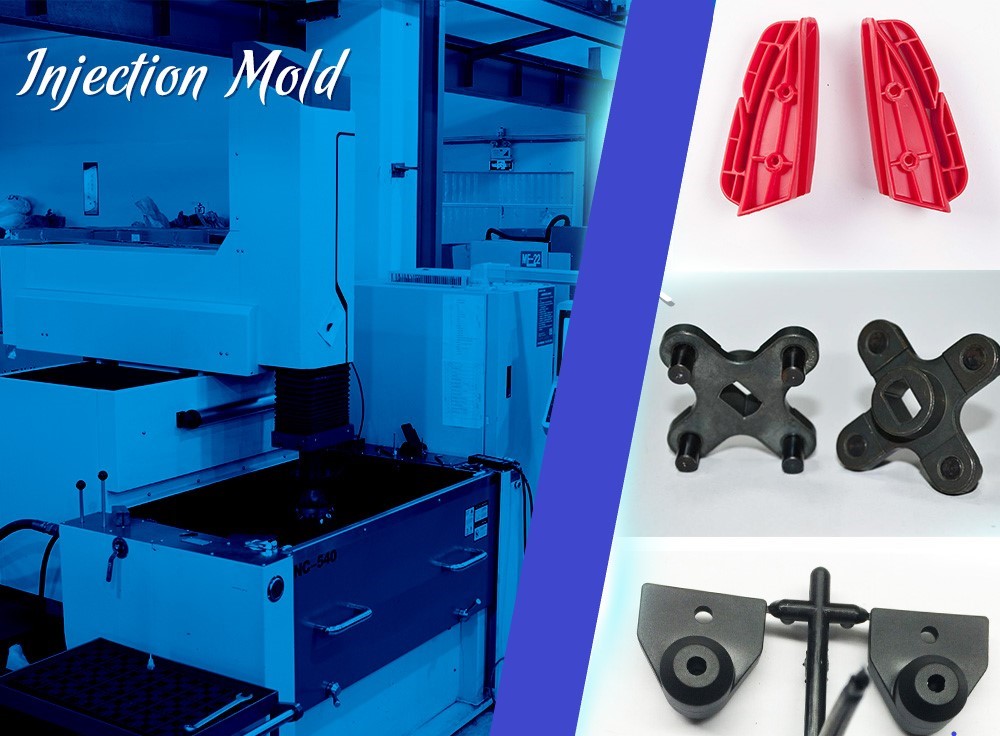

Injection molding is one of the new technologies used in making China Plastic Molding. For further understanding of mold making, the knowledge about injection molding is extremely fundamental to learn. It is a process used for manufacturing purposes.

Besides other industries, injection molding has shown plenty of benefits in product development in China Plastic Molding. In simple words, this means injecting material that is molted in the molds. Injection molding is not only limited to plastics. It has been of great help to other manufacturing companies too.

This kind of molding can be performed using different kinds of a multitude of materials. Every molding process requires different injecting materials with respect to the need of the prospect. The injecting material can vary from molted glass, confectioneries, thermoplastics, and polymers.

It has gained its popularity because of its wide use in almost all the manufacturing industries. It has such compatible qualities that it has a life of its own in the manufacturing processes. You can also say that no industry is complete without using injection molding parameters.

Influence of Injection Molding on China Plastic Molding

Similarly, it has become a widely used option when manufacturing China Plastic Molding. It has laid the foundation for successful yet efficient plastic molding. The basic procedure is very simple yet very important at the same time.

Thermoplastics and polymers play a great deal in plastic molding. Then the conversion of solids into molten form starts. This is a compulsory step to perform the procedure. When in molten form, these are injected into the mold-shaped cavity. The next step is to cool it down for the formation of the actual mold. These formations need approval from dignified personnel because this is going to be the base for the actual plastic product.

Later, this mold plays a very important role in developing the actual pieces. In very sensitive cases, the injected materials need to stay at low temperatures in order to avoid destroying the actual mold. They are so versatile and changeable that they have earned the reputation of being one of the most compatible accessories in any manufacturing unit.

Parameters for Injection China Plastic Molding

This might a simple process, but it carries a great deal of significance in China Plastic Molding. There are a lot of things that need proper supervision and attention. The attention to the parameter details is what matters the most.

When kept in check, these injection parameters can affect the plastic molding by leaving a positive influence. High-quality parts made of plastic are always in demand. And China has made sure to make a mark in the world by providing the best plastic moldings. Their superior ranking has coerced other manufacturers to follow in their footsteps.

When making plastic molds, the organizational veracity of the design and working matters a lot. Hence, the injection parameters great influence on the development of the molds. When incorporating the right injection parameters, you can rest assured that the end product is going to match your consumer’s expectations.

Timing the Injection Molding

Time is money, they say, and yes, it impacts the molding process directly. Timing is very important when injecting the molds. It can make a huge difference in the final product if not done correctly. Injecting time for melted plastic is really crucial.

Even the slightest difference in timing can lower the temperatures to a considerable level. And if the temperature goes below the defined limit, it becomes very difficult and sometimes impossible to make adjustments in the molds. This can badly affect the exterior quality of the final product.

Handling Pressure in Injection Molding

Injection molding is not as simple as it may seem. It is controlled via hydraulic machines that ensure that the right amount of pressure is inserted when the plastic molding is happening. These hydraulic pressure machines compress the pressure that passes on to the molds.

This inserted pressure molds the injected material into the cavity using specific pressure readings. This pressure needs to be very specific; otherwise, the mold resistance may cause problems in the future. This shows that pressure applied by the hydraulics integrates the structural and formation qualities of the mold. It also keeps the thickness of the mold according to the required standards.

Temperature Requirement for Injection Molding

This is an extremely important parameter for plastic molding. That is why this is to emphasize enough how important is the role of temperature control in the whole process. Regulating the right temperatures at the right time can make or break the whole game. Pressure and temperature work mutually, so they help to achieve the ultimate goal.

Regulating the right temperature helps in quality maintenance too. Modeling the plastic takes a great deal of precision. Without precision in temperature control, the design results can vary greatly from the original design.

Integration of Pressure and Time

There is a series of steps that complete the plastic molding process. But the major task that happens in the process is the integration of pressure and time. This is crucial in many ways because it lays the foundation of the mold on which further process takes place.

When you do not time the integration of pressure properly, it may result in a disfigured, uneven, thick, or even totally different design.

Conclusion

China Plastic Molding has achieved a renowned position in the industrial market. Due to its resilience, it is becoming more popular day by day. Although it is affected by many external factors, there is no need to worry. There are a few parameters to follow to produce unmitigated desired results. Because these injection parameters play a vital role in the whole process, they carry a great significance in plastic molding.

To learn more about Plastic Moulding, reach out to us today.

You May Also Read: OEM Plastic Molding – How this Industry Can Grow Faster