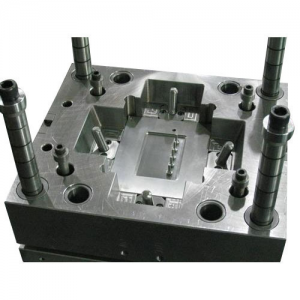

Plastic injection mold in coffee maker design process

Plastic injection mold in coffee maker design is the first and most important step in the plastic injection processing process, affecting the entire production process. The rational design of plastic injection molds will help increase efficiency, reduce design time, and speed up the process of bringing products to market.

Plastic injection mold design sequence

Professional mold in coffee maker oompany is a unit specializing in high-quality mold processing. further, the company's mold design process is needed to carry out in 4 steps.

Design for Manufacturing DFM production

Design for manufacturing takes care of manufacturing issues throughout the entire product development process. further, the design for production effectively saves production costs while ensuring product quality.

During the design phase for DFM production, the design engineer will perform the following tasks:

firstly, read product drawings and grasp the technical requirements, structural shape of the product.

- Secondly, compare with product data on 2D, 3D models

- Thirdly, analyze 2D, 3D product data from there to give flow simulation and determine the injector position

- Fourthly, determination of parting face, mold in coffee makerexit angle

- Fifthly, arrange the necessary structures in the mold design: Ejector pin, slide, lifter.

- at seven, based on the shape and complexity of the product, analyze and evaluate to select the appropriate technology option.

All changes and design plans for production are designed and accepted by the unit as a plastic injection mold . Moreover, they come to a consensus from the customer.

What is mold layout design?

Design mold layout design drawings of mold assembly layout, this is the stage of calculating and designing the exact plan of mold assembly

Assembly drawings need the following sequence of steps:

- Calculate the shrinkage coefficient of the product based on the characteristics of the material and product size to avoid problems with warping, surface convexity.

- Flip the product image to ensure correct mounting on the Base

- Flip the product image so that it is in the correct direction to install it on the Base

- Calculating mold in coffee makerinsert bag size

- Design of mold structural parts

- Pins layout and bolt positions to fix Insert and Base

- Arrangement of mold accessory parts according to the type of 2-plate or 3-plate mold

- Layout bolt position to catch (fixed) Insert and Base

- Arrange the accessories for the mold according to the structure of 2-plate mold or 3-plate mold

- Determination and inspection of mold parts dimensions

What do you know about 3D mold design?

Is the use of software to simulate a layout design in 3D? Mold details with complex structures need to use 3D designs to facilitate the fabrication and inspection process.

In order to avoid errors and easily controllable, the 3D design is done through the steps of insert design, mold in coffee maker base design and complete 3D mold design.

Design engineering drawings

Machining technology drawing is a drawing that fully shows the technical requirements and characteristics of the details.

In order to get qualities machining technology drawings, design engineers need to understand products requirements. The drawing should clearly show the machining sequence before transferring to another part.

What role does the correct implementation of plastic injection mold design play?

Implementing the correct order of plastic mold in coffee maker design plays an important role. It has significance in the process of manufacturing and manufacturing plastic injection molds. Moreover, it is helpful in meeting well the processing and manufacturing needs and requirements of customers. further, it is the premise to perform the following processing steps

- Make the production process quick and convenient

- Avoid mistakes made in the machining process

- Contribute to saving mold production costs

- Shorten production time, bring products to market soon

Designing plastic injection molds in the correct order requires systematic and prescriptive steps. Attention should be there to consulting the user, the mold in coffee maker department.

Using CAD/CAM/CNC technology in mold making

CAD/CAM/CNC technology is an outstanding achievement of science and technology. It is widely applicable in the field of mold making. Especially, to produce mold products with complex shapes, meeting the requirements of the industry.

Currently, in mold making, there are much different mechanical engineering software, but CAD/CAM/CNC technology brings outstanding advantages. Moreover, knowing these design software is a necessary factor, producing many quality mold products.

Using CAD/CAM/CNC technology in mold in coffee maker helps improve the automation of the modern mold industry, contributes to the advancement of production capacity, and increases the competitiveness of enterprises. Mold industry in the market.

What is a CAD design software?

CAD is software that produces a mold design with a full range of shape, size, tolerance, and product structural features. CAD design engineers must have professional capacity and implementation skills to be able to meet the needs of mold design, even for products with complex technical requirements.

Using CAD software in design brings great value, helping to improve design productivity, product quality, shorten production time, and quickly bring to market mold products at competitive prices.

Design drawings are made by engineers on CAD software and analyzed easily and accurately. Moreover, they are helpful to quickly get the most complete design by mold in coffee maker.

CAM software in mold making

CAM software is used for the purpose of building a condition base and automating the mold manufacturing process. In other words, after finalizing the design by engineers in CAD software, it will be carefully checked, analyzed, calculated and then imported into CAM software. After that, the CNC machine will conduct machining.

CAM software is linked with CAD, thereby helping better the design process, bringing outstanding efficiency and enhancing the automation of the machine system.

CAM software is of great significance in automating the production process, helping to monitor and manage production quickly, easily, and automatically.

CNC machines in the mold engineering industry

CNC machines are modern machines that use software to control tools such as lathes, milling machines, and cutting machines.

Currently, most CNC machines use Fanuc operating system. The CAD/CAM software, after designing the mold in coffee maker, will produce a code; the CNC machine will read this code and execute it to process the mold product.

Using CNC machines in the mold making process is a leap in technology, helping to increase automation in the production process. Many CNC machines can run automatically at the same time, producing products with uniform quality in a certain processing time.