3 Tips for Buying High-Quality Injection Moulding Machine Parts

Injection molding machines consist of several parts, including the hopper, screw, barrel, clamping unit, injection nozzle, and control panel. Hopper: This is where plastic pellets are stored before being fed into the machine. Screw: The screw is responsible for transporting the plastic pellets from the hopper to the barrel, where it is heated and melted.

Essential Spare Parts for a Plastic Injection Moulding Machine

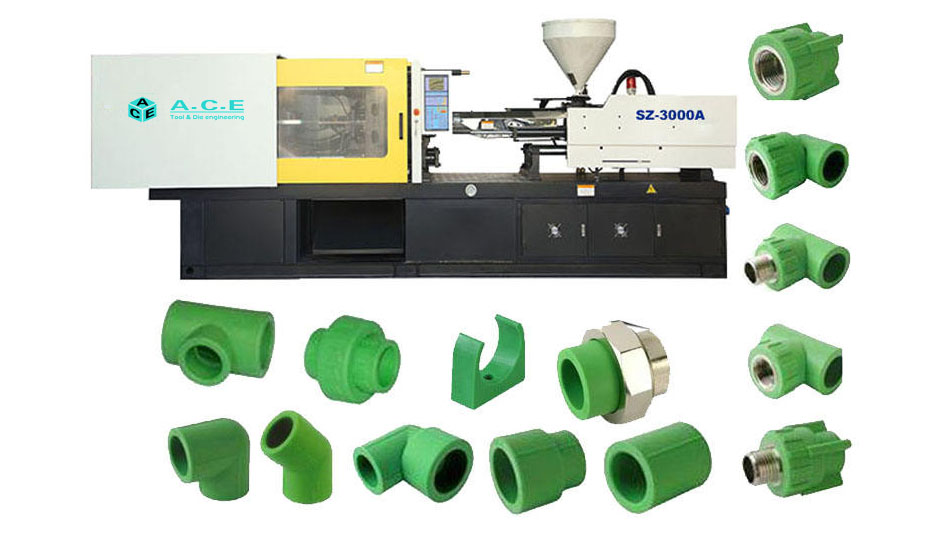

Plastic injection molding machine spare parts are replacement parts for use in plastic injection molding machines. These spare parts are used to replace worn or damaged parts in the machine to ensure that it continues to operate correctly and efficiently. Some examples of spare parts for plastic injection molding machines include: Screws and barrels: These

Experience the Magic of Double Colour Plastic Injection Moulding Machine!

Are you looking for a more efficient way to produce high-quality plastic parts? Then double colour plastic injection moulding machine is the perfect solution for you. In this blog, we will discuss everything you need to know about double colour plastic injection moulding machine, from its introduction to its future. So let’s get started! Introduction

Unveiling the Cutting-Edge Technology of Advanced Injection Moulding Machine!

An advanced injection molding machine is a machine that is capable of producing high-quality, complex parts with precise dimensions. These machines typically have advanced features such as multiple stages of injection, specialized nozzles, and precision temperature control. They can also be programmed for automation and can be integrated with robotics and other advanced technologies. These