The Benefits of Injection Moulding Materials for Your Business

Injection molding is a manufacturing process that can use a variety of different materials, including plastics, metals, and ceramics. The most commonly used materials in injection molding are thermoplastics, which can be melted and reshaped multiple times. Some examples of thermoplastics that are commonly used in injection molding include: Polyethylene (PE): This is the most

The Environmental Impact of Injection Moulding – What You Need to Know!

Injection molding is a manufacturing process that can have a significant environmental impact. One major concern is the release of pollutants, such as volatile organic compounds (VOCs), particulate matter, and plastic particles, into the air during the production process. Additionally, the plastic materials used in injection molding are often derived from non-renewable resources and can

Injection Moulding Products: The Benefits of Creating Custom Products

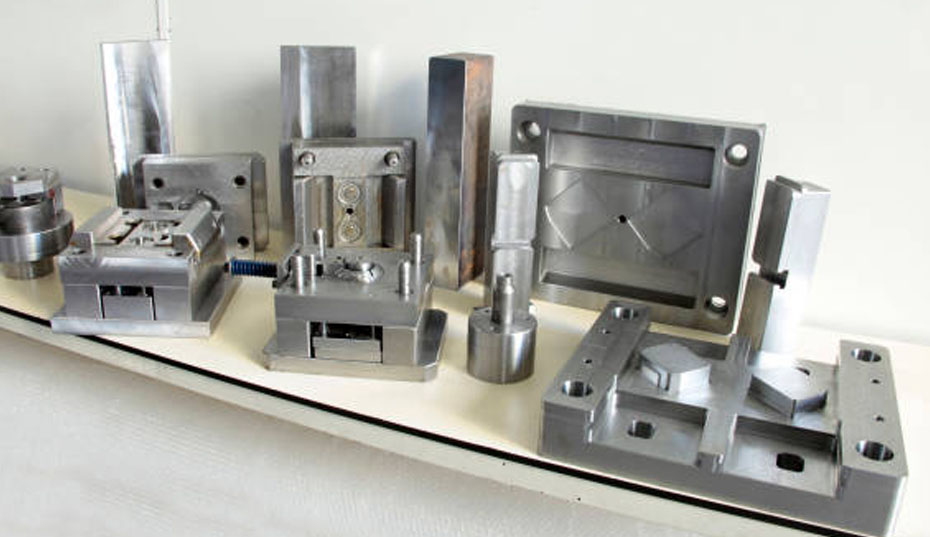

Injection molding is a manufacturing process in which a material, such as plastic, is heated and then injected into a mold. The mold is a hollowed-out form in the shape of the desired product. The material then cools and solidifies, taking on the shape of the mold. Injection molding is used to create a wide

A Revolution in Injection Moulding CNC Machines: Unlocking New Possibilities!

Injection moulding CNC machines have been one of the most revolutionary inventions in the manufacturing industry. They have revolutionized the way businesses manufacture products and how they go about the production process. The evolution of injection moulding CNC machines has allowed businesses to produce more accurate and efficient products with greater accuracy and precision. In