8 Quality Checkpoints for Tooling Design in Manufacturing

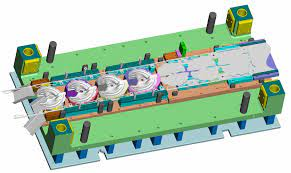

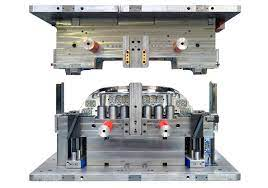

More and more companies are looking for new methods and tooling design that optimizes the manufacture of parts and products. Thanks to technology, there have been many improvements in process automation and freight transport. Industries are producing on a large scale to meet demand and increase the customer base. However, not worrying about the quality and

5 Factors you should consider before Hiring Stamping Mould Services in 2021

One of the most common questions for those looking to launch a product from plastic injection is: “How much does a plastic injection mold cost?” It is a pertinent question, since stamping mould represents the most significant expense in the initial production costs. There are numerous factors that influence the determination of the total cost. In this article,

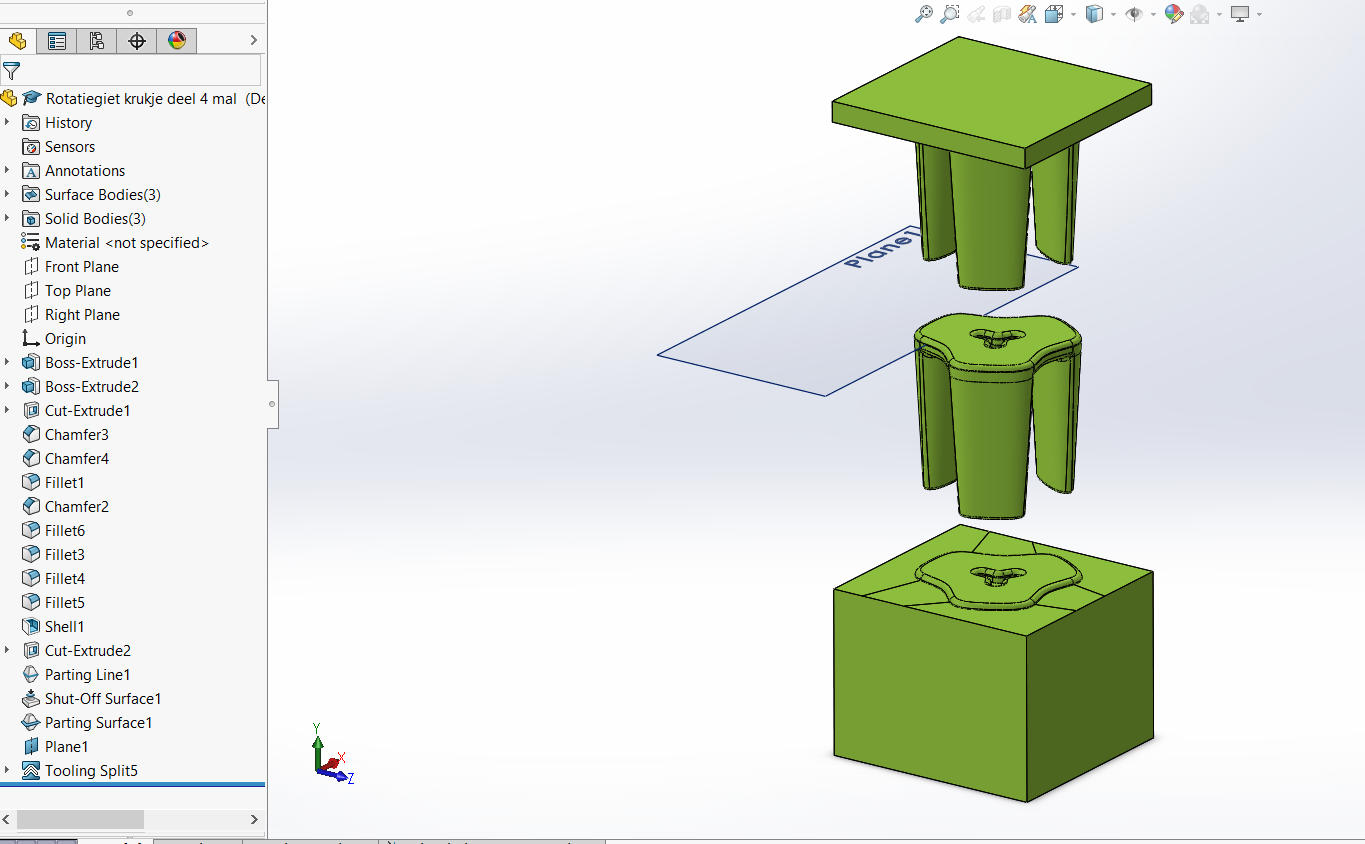

How does prototype tooling help in final product development?

What is rapid tooling? How fast is rapid mold making and what are the advantages? Prototype tooling is also called prototype mold or soft mold, but it is essentially an injection mold, which is a tool that can produce large quantities of parts quickly and cheaply. Only when the product development project is 90% sure of

How does mold design work for plastic windows for homes?

Thermoforming is one of the most popular methods for processing mold design polymer sheets. Moreover, it allows you to quickly and inexpensively obtain products of the desired configuration. For advertisers and designers, this is a great opportunity to create spectacular advertising signs with three-dimensional elements, original racks and POS materials. Plastic sheet mold design forming: advantages Molding