How many stages are there in the process of high-gloss mold?

How high gloss adds value to modern plastic molded parts? Today people increasingly prefer to use products designed by a high gloss mold. In fact, the attractive gloss of plastic products decides their real value. This attractive gloss adds value to different molded products. As you know that all plastic products are produced by using

What are the applications of medical mold in plastic infusion?

What is medical injection molding? Fabricating therapeutic components and gadgets utilizing restorative review plastic materials that are tough, dependable, and meet FDA controls is the pith of medical infusion molding. Different medical mold has an implementation in this strategy. The restorative plastic infusion molding method is expense efficient, and perfect for tall volume generation runs and

What are types of plastic molding for package plastic part?

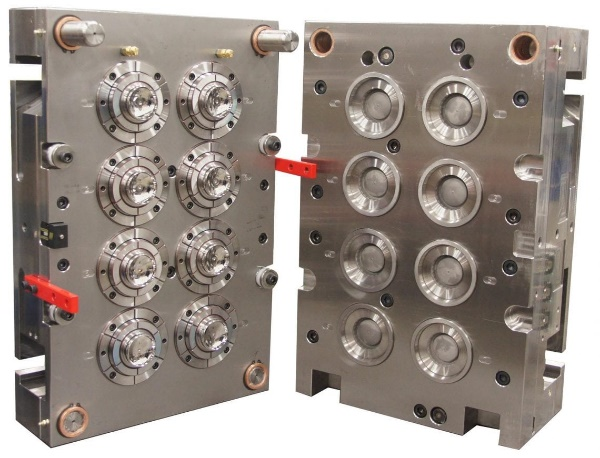

What is plastic injection molding? Plastic infusion molding employments granular resins to deliver items extending from car and plane components to capacity holders, melodic instrument parts, and hair combs. When molding plastics, talc or fluid polymers such as polyethylene or polypropylene are put into an empty form so the polymer can take its shape. One

What is automotive mold| Advantages/Cost in 3D Injection Molding?

Most Common Mold Materials Today injection molding has become one of the most popular production processes for molding automotive parts. Moreover, automotive mold is an extremely important part of the automobile industry. In fact, these molds not only use thermoplastics but also make use of metals as well as several other materials to mold according to