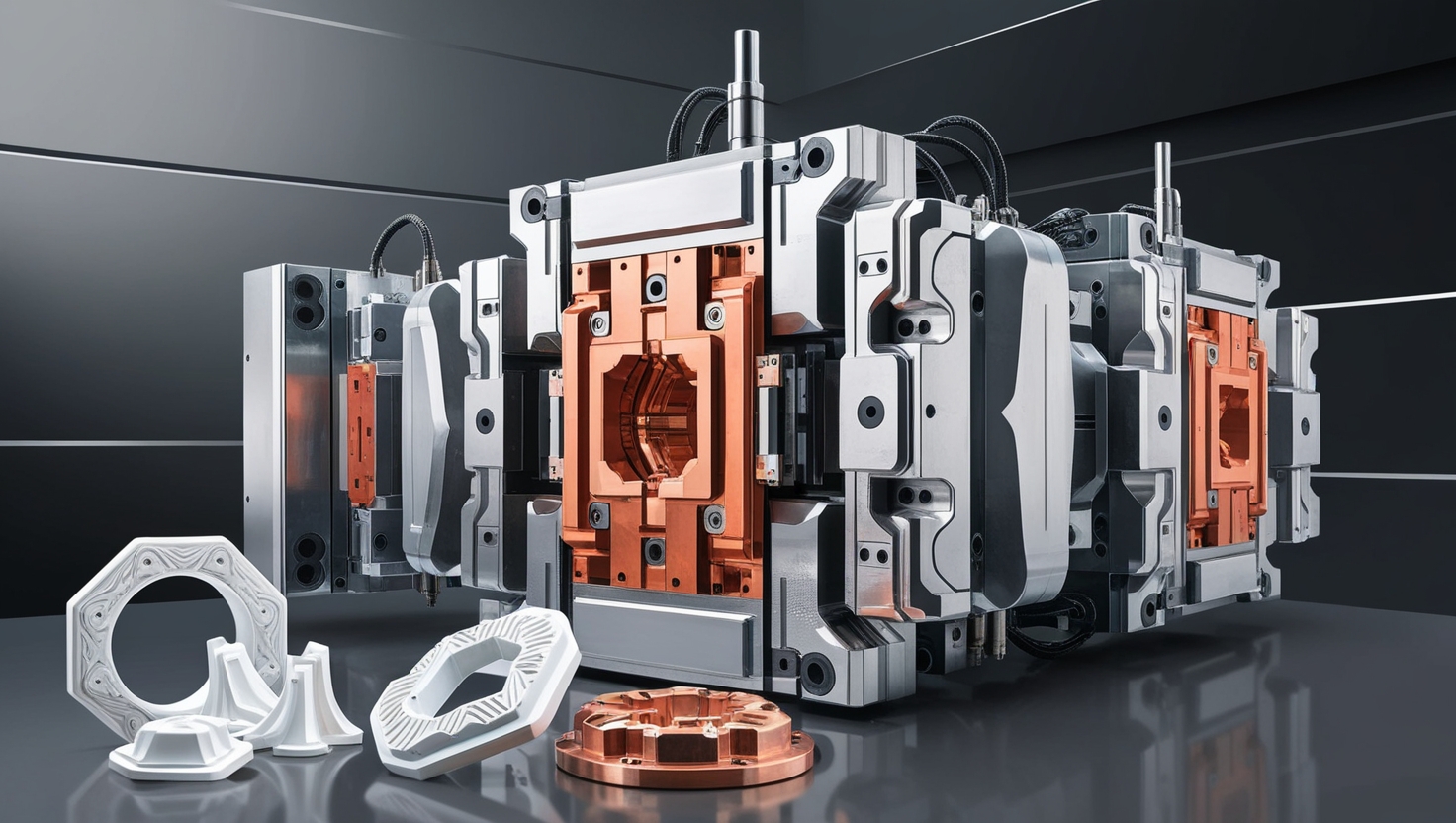

Plastic Tooling for Complex Shapes: Precision Molding for Intricate Designs

Plastic tooling plays a crucial role in modern manufacturing, enabling the production of intricate and highly precise components for various industries. From automotive parts to medical devices, the demand for complex plastic shapes continues to rise, pushing manufacturers to develop advanced tooling techniques to maintain accuracy and efficiency. As technology evolves, plastic tooling has become

Precision Plastic Tooling for Consumer Products: Quality & Efficiency

Plastic tooling is essential in the manufacturing of consumer products, enabling mass production of high-quality, durable, and cost-effective plastic components. From household appliances and electronic enclosures to packaging and toys, plastic tooling allows manufacturers to produce intricate designs with precision and consistency. With advancements in manufacturing technologies, plastic tooling has evolved to accommodate complex geometries,

Plastic Tooling for Electronics: Techniques, Materials, Challenges & Future Trends

Plastic tooling in electronics manufacturing involves designing and producing molds or tools used to shape plastic components for various electronic devices. These components include casings, connectors, switches, and circuit board housings. Plastic tooling enables high-precision, durable, and cost-effective production, ensuring that electronic products meet industry standards for performance, durability, and aesthetics. Applications of Plastic Tooling

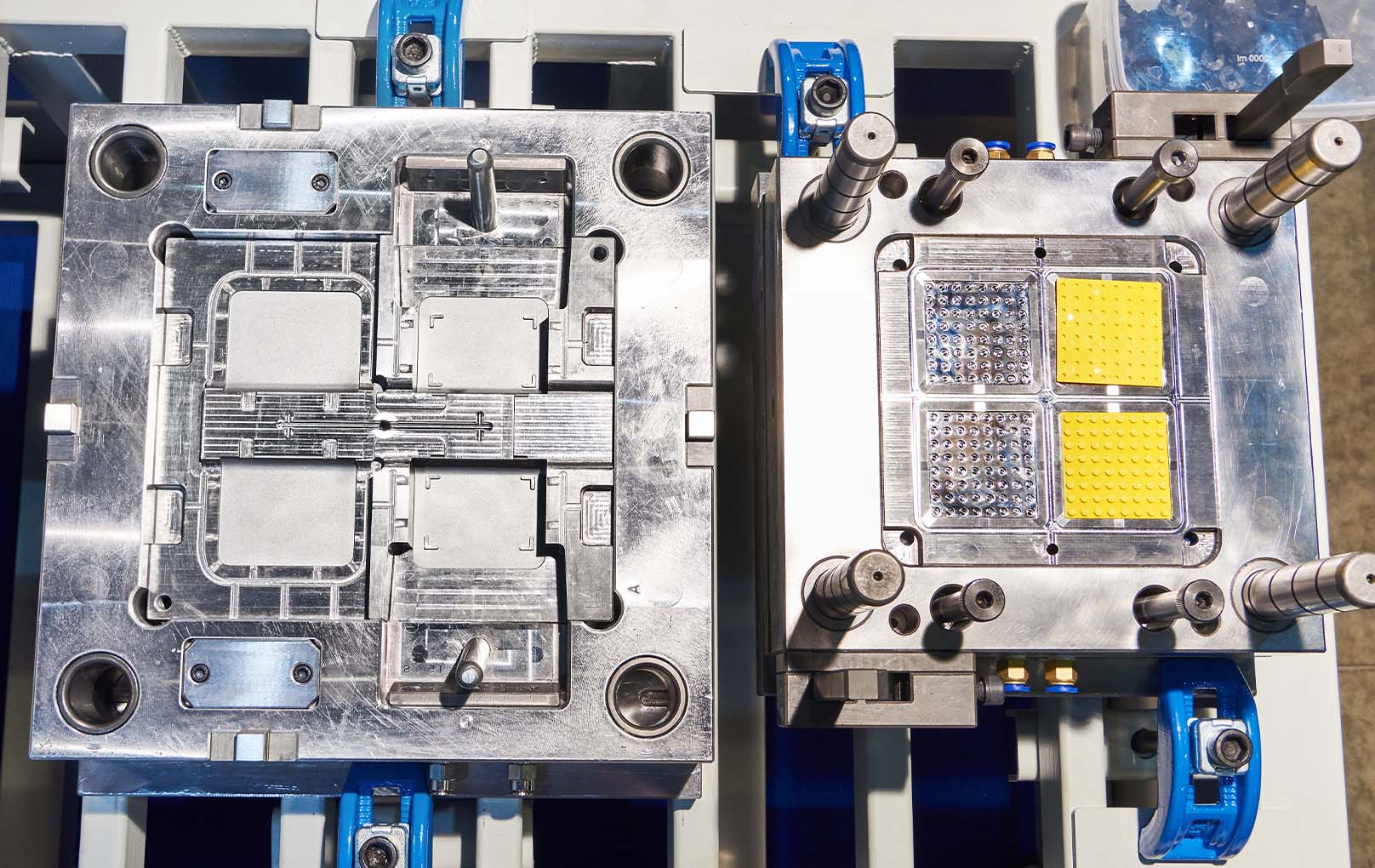

Plastic Tooling For Injection Molding: Processes, Challenges, and Best Practices

Plastic tooling is an essential part of the injection molding process, which is widely used in the manufacturing of plastic parts for various industries, including automotive, medical, consumer goods, and electronics. The tooling refers to the molds and dies used to shape molten plastic into precise and repeatable forms. Without high-quality tooling, manufacturers would struggle