Plastic Tooling for High-Volume Production: Processes, Advancements & Future Trends

Plastic tooling for high-volume production refers to the specialized molds and tools used to manufacture plastic components in large quantities. These tools shape, form, and process plastic materials into finished products using various manufacturing techniques such as injection molding, blow molding, compression molding, and thermoforming. Plastic tooling includes the molds, dies, and associated components used

Plastic Tooling for Large Parts | Molding, Materials & Innovations

Plastic tooling is a critical element in the injection molding process, particularly when producing large plastic parts. The tooling, or the mold, determines the final shape, quality, and consistency of the parts produced. Large part molding is commonly used in automotive, aerospace, construction, and industrial applications, where components such as bumpers, panels, and enclosures are

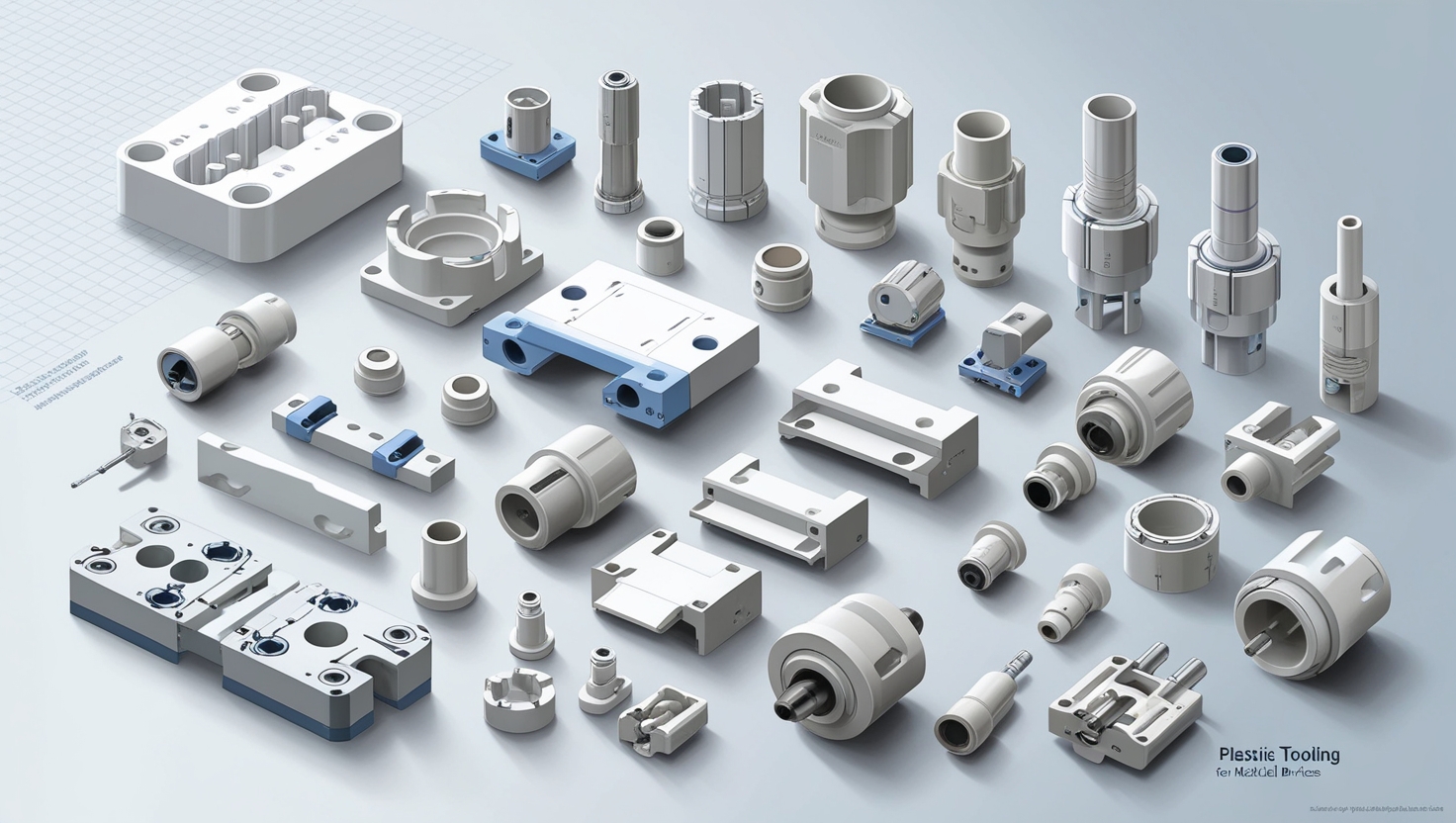

Plastic Tooling for Medical Devices: A Comprehensive Guide

Plastic tooling plays a crucial role in the medical device industry, enabling the production of high-precision, durable, and biocompatible components. With advancements in material science and manufacturing technologies, plastic tooling has become a preferred choice for creating medical devices, from syringes and catheters to complex surgical instruments. The demand for cost-effective, scalable, and reliable solutions

Plastic Tooling for Packaging | High-Volume Molding & Innovation

Plastic tooling is a cornerstone of modern packaging manufacturing, enabling the mass production of high-quality, cost-effective, and functional packaging solutions. From food containers and beverage bottles to pharmaceutical blister packs and industrial packaging, plastic tooling ensures precision, consistency, and durability. As the demand for sustainable and innovative packaging grows, manufacturers are adopting advanced plastic tooling