Injection Mold Tooling: The Ultimate Guide for Manufacturers

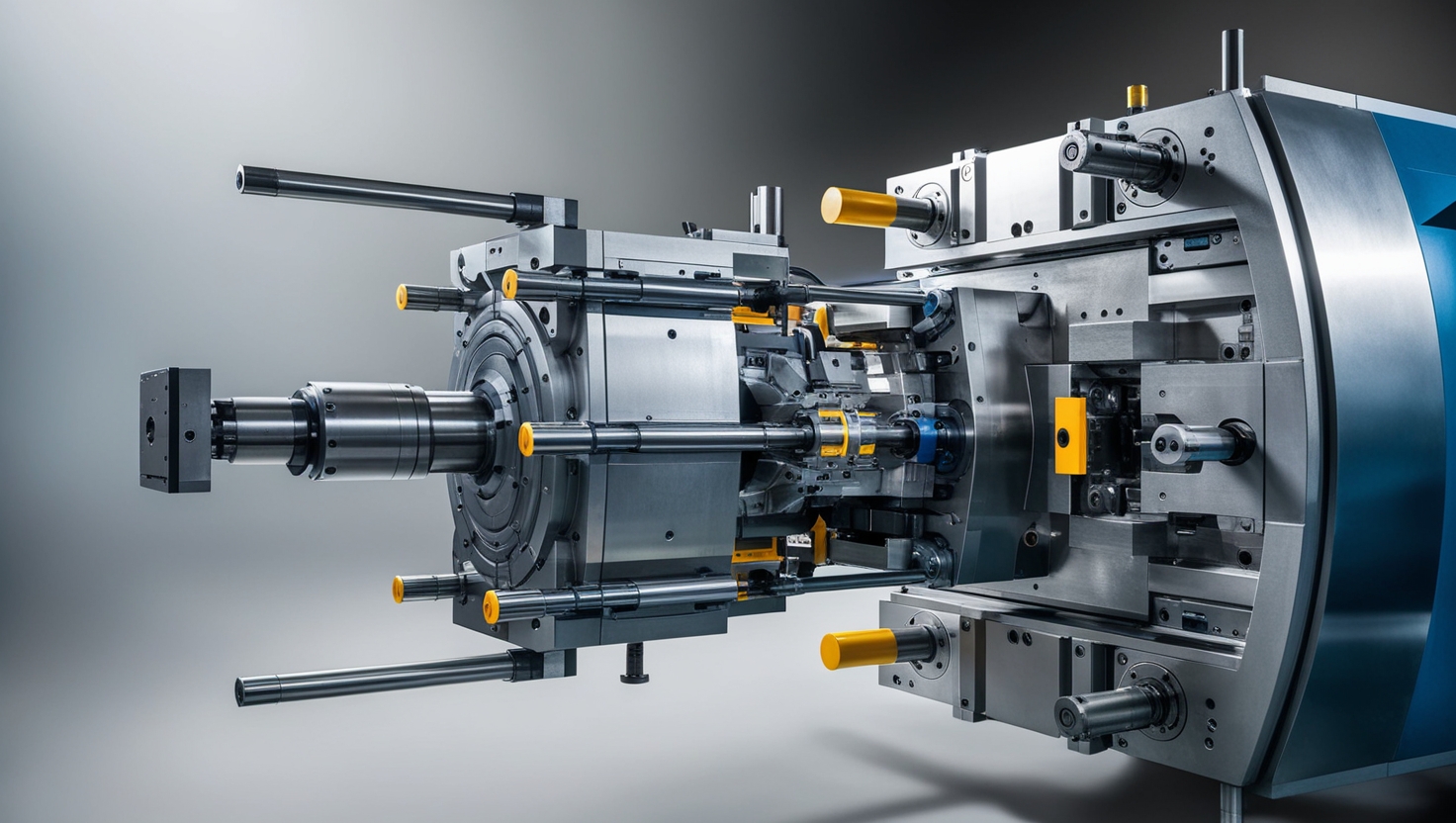

Injection mold tooling is an essential part of modern manufacturing, allowing for the mass production of plastic parts with precision and efficiency. Whether you’re developing consumer goods, automotive components, or medical devices, understanding how injection mold tooling works is crucial for ensuring high-quality results. This guide explores everything you need to know about injection mold

Custom Tooling for Plastic Molds: Everything You Need to Know

Have you ever wondered how plastic toys, containers, or even car parts are made? They all come from molds! Molds are special tools that shape melted plastic into the products we use every day. Custom tooling for plastic molds means making these molds in a way that fits the exact needs of a product. It

Injection Mold Tooling for Plastic Parts: A Complete Guide

Injection mold tooling is a crucial element in plastic manufacturing, allowing businesses to produce high-quality parts with precision and efficiency. The right tooling ensures consistency, durability, and cost-effectiveness in mass production. This guide will cover everything you need to know about injection mold tooling, from its components and materials to costs and best practices. What

Understanding Injection Molding for Medical Devices

Did you know that injection molding is transforming the medical device industry? This advanced manufacturing process enables the production of high-quality, precise, and cost-effective medical components. What Is Injection Molding for Medical Devices? Injection molding for medical devices involves heating medical-grade plastics until they melt, then shaping them into precise forms using specialized molds. This