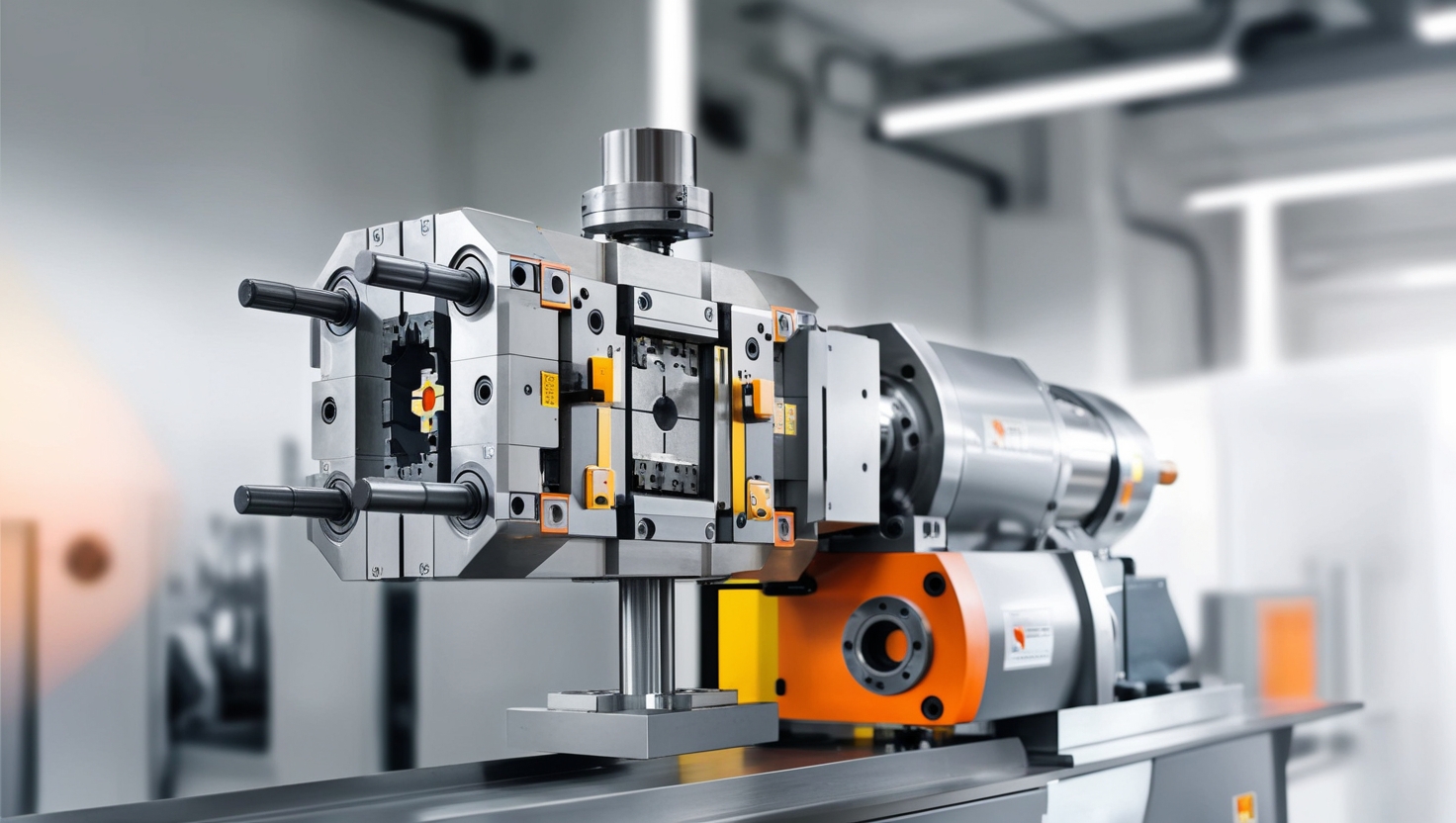

Understanding Injection Tooling for Plastic Products

Plastic products are everywhere—packaging, automotive parts, medical devices, and consumer goods all rely on plastic manufacturing. At the heart of this process is injection molding, a method that allows manufacturers to produce high-volume, high-precision plastic parts. But what makes it all possible? Injection tooling, The quality and efficiency of injection tooling determine the success of

Low-Volume Plastic Tooling: Efficient Solutions for Small Batch Production

Low-volume plastic tooling is an essential manufacturing approach that fills the gap between prototyping and mass production. It allows businesses to create high-quality plastic components in limited quantities, typically between 100 and 10,000 units. This method provides a cost-effective and flexible alternative to traditional high-volume injection molding, making it an attractive option for industries that

Low-Volume Plastic Injection Molding: Cost, Benefits & Comparison

Manufacturing is no longer just about mass production. Companies are increasingly looking for flexible, cost-effective solutions for smaller product batches. That’s where low-volume plastic injection molding (LVPIM) comes in. Unlike traditional injection molding, which prioritizes high production volumes, LVPIM is optimized for runs as small as 100 to 10,000 units. Whether for prototyping, bridge production,

Guide to Plastic Injection Mold Design: Key Principles and Best Practices

Plastic injection molding is a process used to create plastic parts by injecting molten plastic into a mold. The design of the mold is one of the most important steps in this process. A well-designed mold helps create high-quality parts, reduces defects, and improves production efficiency. This blog will explore how plastic injection molds are