Plastic Injection Mold Tooling: A Complete Guide

Plastic injection mold tooling is a crucial step in the manufacturing process that determines the quality, cost, and efficiency of plastic part production. The tooling process involves designing and manufacturing the molds used to shape plastic parts. A well-made mold ensures precise, repeatable, and durable products. This guide explains the different types of tooling, materials

Plastic Injection Molding: A Complete Guide

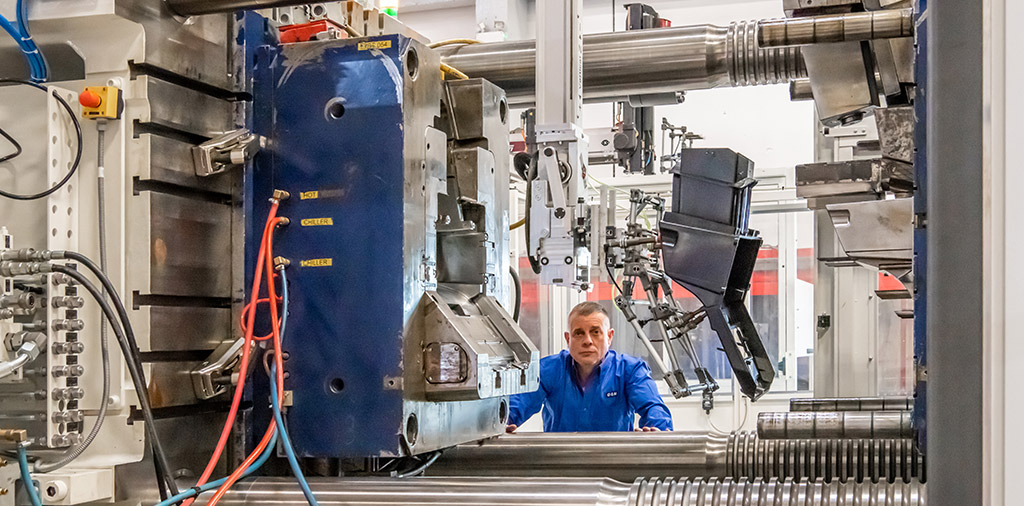

Plastic injection molding is one of the most widely used manufacturing processes for producing plastic parts. It is known for its ability to create high-quality, durable, and cost-effective products in large quantities. This guide will explain how plastic injection molding works, its advantages, the types of machines used, common materials, design considerations, and typical applications.

The Complete Guide to Plastic Injection Molding Companies: Industry Insights, Trends, and Comparisons

Plastic injection molding is a cornerstone of modern manufacturing, responsible for producing everything from automotive components to medical devices and consumer electronics. This process enables high-volume production of complex, durable plastic parts with excellent precision. In this deep dive, we’ll explore the plastic injection molding industry, highlight leading companies, analyze trends, and discuss key factors

Plastic Injection Molding for High-Volume Production: A Comprehensive Guide

Plastic injection molding stands as a cornerstone in modern manufacturing, enabling the mass production of intricate plastic components with remarkable precision and efficiency. When it comes to high-volume production, this process offers unparalleled advantages, making it the go-to method for industries ranging from automotive to consumer electronics. In this guide, we’ll explore the intricacies of