A Guide to Identifying the Best Plastic Types for Injection Molding

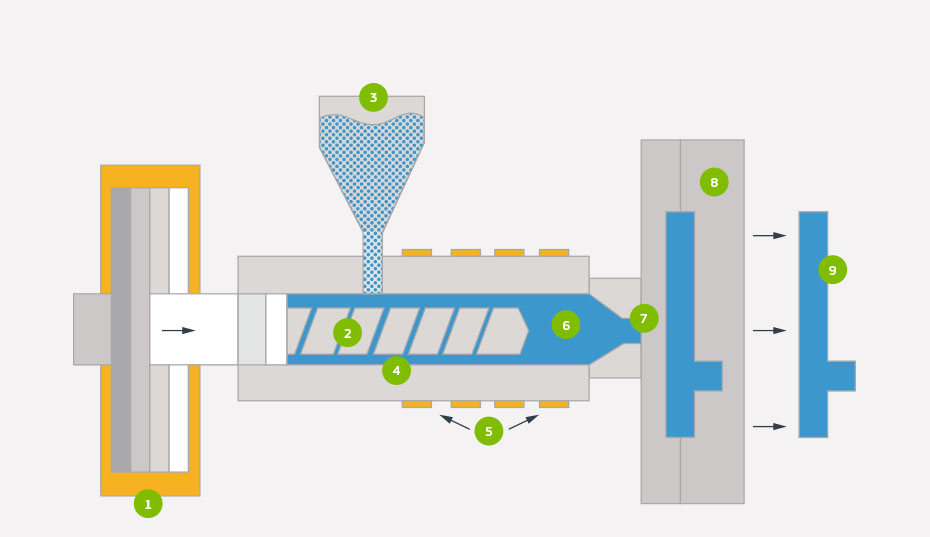

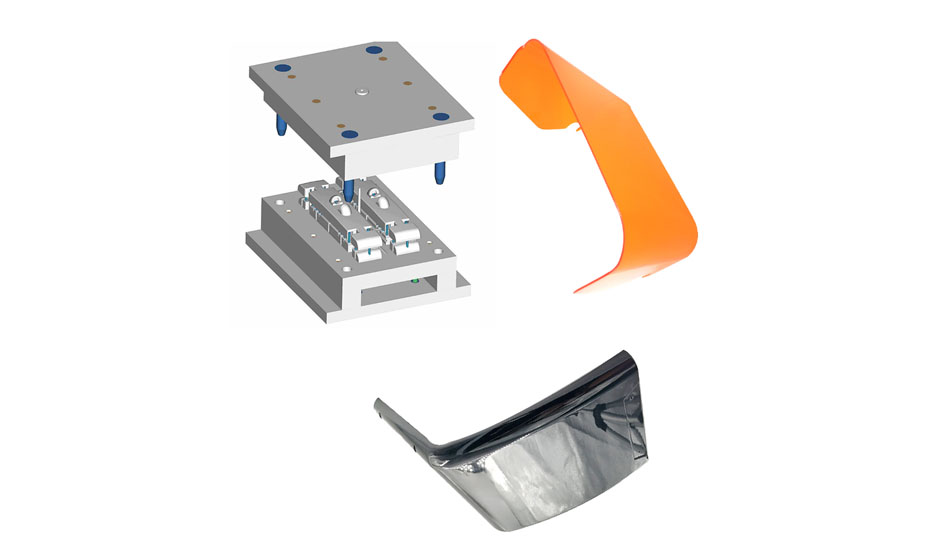

Injection molding is a manufacturing process that involves injecting molten plastic into a mold to form a desired shape. There are many different types of plastics that can be used in injection molding, including: Polyethylene (PE) – a thermoplastic polymer that is lightweight, flexible, and durable. It is commonly used in packaging, consumer goods, and

The Benefits of Plastic Injection Molding Materials

Plastic injection molding is a manufacturing process in which plastic material is melted and injected into a mold to create various parts and components. Some common materials used in plastic injection molding include: Polyethylene (PE) Polypropylene (PP) Acrylonitrile butadiene styrene (ABS) Polyvinyl chloride (PVC) Polystyrene (PS) Nylon (PA) Acetal (POM) Polycarbonate (PC) Acrylonitrile-styrene-acrylate (ASA) Polyphenylene

How Much Does Plastic Injection Molding Cost?

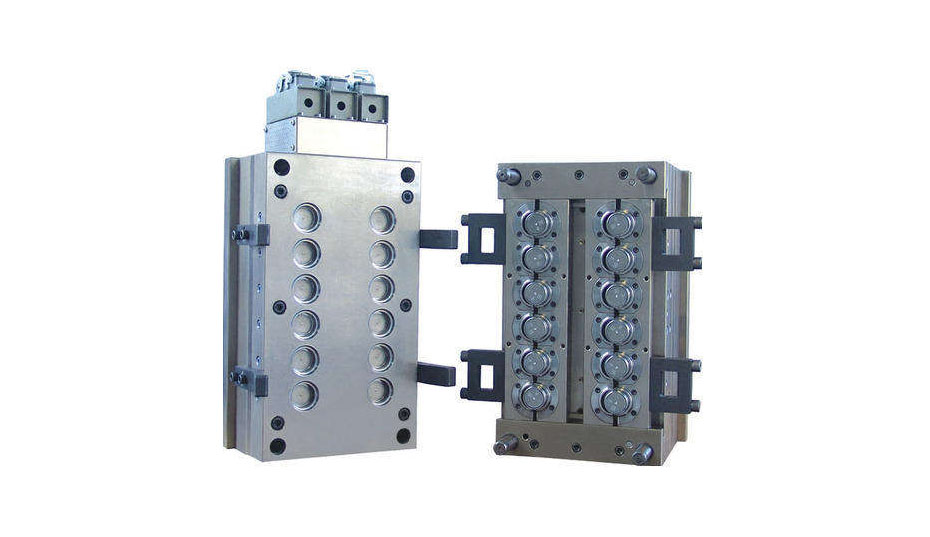

If you’re looking for a cost-effective manufacturing process for your plastic products, plastic injection molding is the way to go. Plastic injection molding is a reliable, repeatable, and cost-efficient manufacturing process that produces high-quality parts with tight tolerances and intricate details. But just how much does plastic injection molding cost? In this blog post, we’ll

The Benefits of Medical Plastic Injection Molding Companies

Have you ever wondered what medical plastic injection molding companies do? Or what are the benefits of working with them? If you have, you’re in luck. In this blog, we’ll take a detailed look at medical plastic injection molding, the process, and the benefits of working with a medical plastic injection molding company. We’ll also