Injection Moulding Products: The Benefits of Creating Custom Products

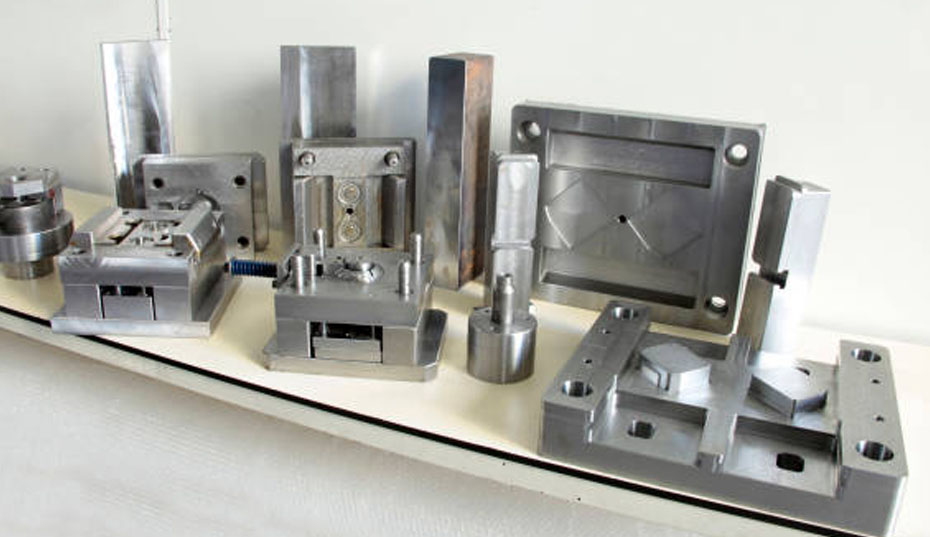

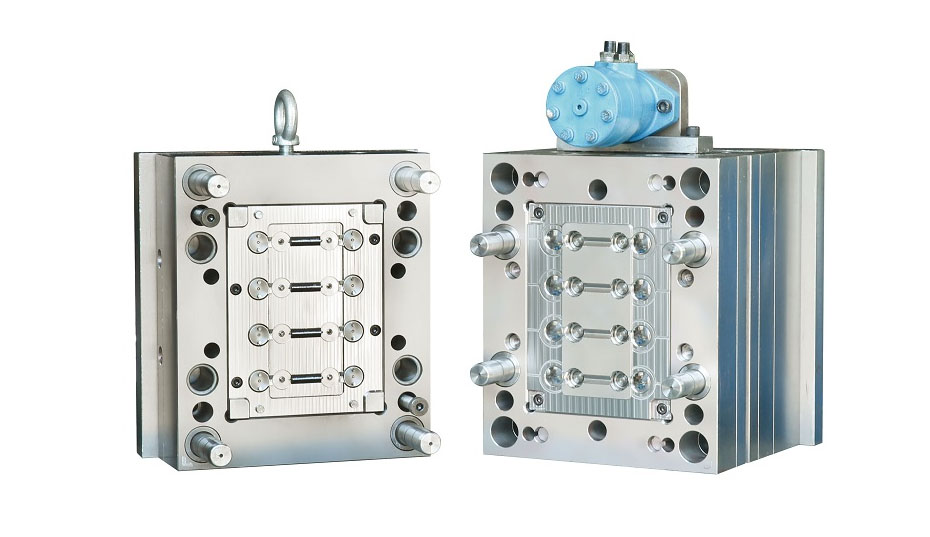

Injection molding is a manufacturing process in which a material, such as plastic, is heated and then injected into a mold. The mold is a hollowed-out form in the shape of the desired product. The material then cools and solidifies, taking on the shape of the mold. Injection molding is used to create a wide

A Revolution in Injection Moulding CNC Machines: Unlocking New Possibilities!

Injection moulding CNC machines have been one of the most revolutionary inventions in the manufacturing industry. They have revolutionized the way businesses manufacture products and how they go about the production process. The evolution of injection moulding CNC machines has allowed businesses to produce more accurate and efficient products with greater accuracy and precision. In

Medical Injection Moulding Cleanroom: A Comprehensive Guide!

A medical injection moulding cleanroom is a sterile environment that is designed to limit airborne particles, provide a stable and controlled temperature, and create a safe working environment for medical device manufacturing. Such cleanrooms are typically used in pharmaceutical and medical device manufacturing, medical research, and medical device assembly. In this guide, we will explore

How Long Does Injection Moulding Take? Uncover the Surprising Answers!

The time it takes to complete an injection moulding process can vary depending on several factors such as the size and complexity of the part, the material used, and the number of parts being produced. The cycle time, which is the time it takes for the machine to inject the material, cool and eject the