Plastic Tooling Design: Precision Engineering for High-Quality Molded Parts

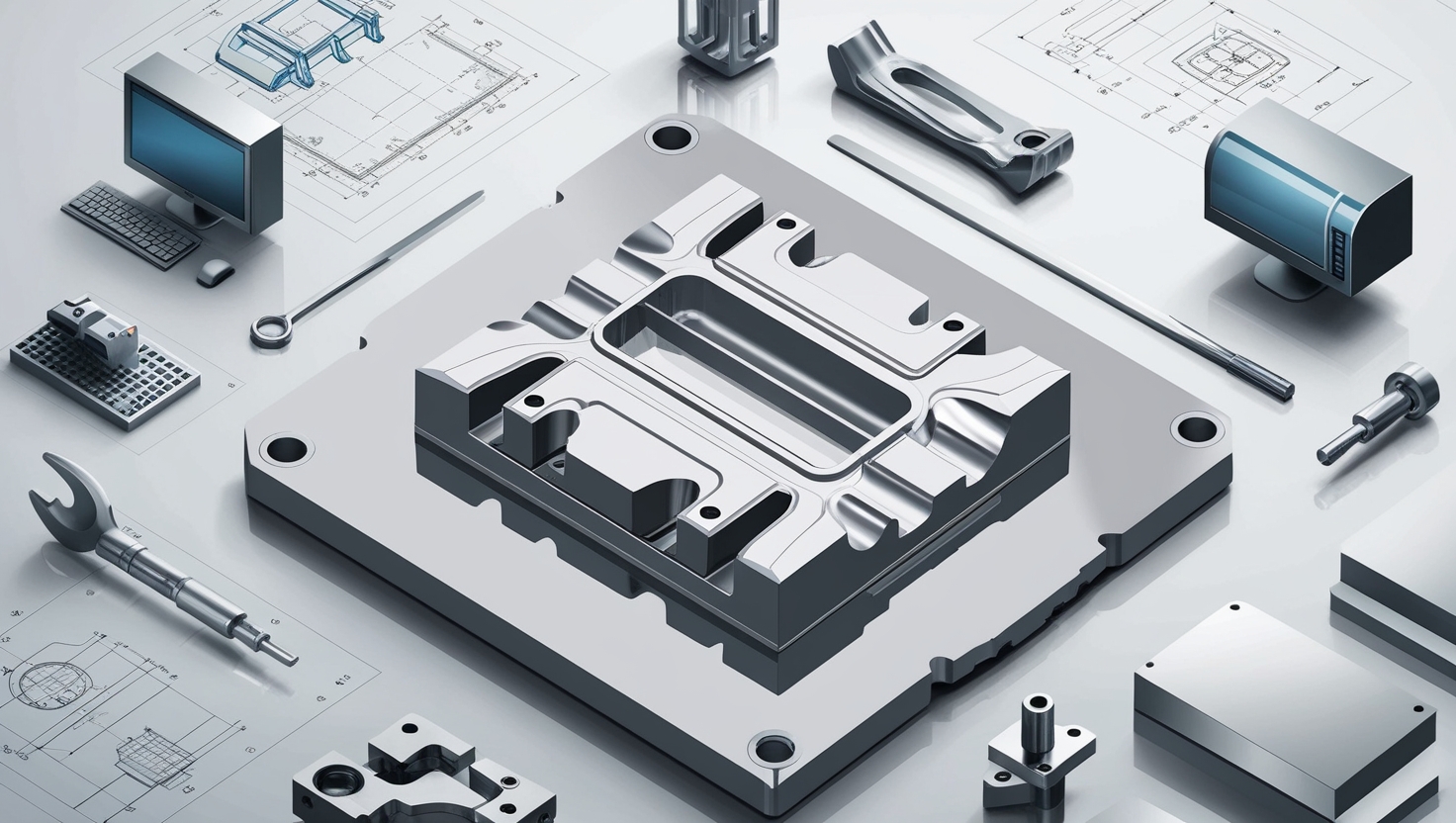

Plastic tooling design is a critical aspect of modern manufacturing, ensuring the production of high-quality, precise, and durable plastic components. It involves the development of molds, dies, and fixtures used in various molding processes such as injection molding, blow molding, compression molding, and rotational molding. With the increasing demand for complex geometries, high-performance materials, and

Plastic Tooling Design & Fabrication: Precision Molds for High-Quality Production

Plastic tooling plays a critical role in modern manufacturing, enabling the mass production of high-quality plastic components with precision and efficiency. Whether for automotive parts, medical devices, or consumer electronics, plastic tooling ensures consistency and durability in production. This article explores the design and fabrication of plastic tooling, covering materials, processes, challenges, and future trends.

Plastic Tooling for Automotive: A Comprehensive Guide

Plastic tooling has revolutionized the automotive industry by enabling the production of lightweight, cost-effective, and high-performance components. With the growing demand for fuel-efficient vehicles and electric mobility, plastic tooling plays a crucial role in reducing vehicle weight while maintaining structural integrity. This article explores the role of plastic tooling in the automotive sector, covering its

Plastic Tooling for Batch Production: A Comprehensive Guide

Batch production is a manufacturing method where a set number of identical products are produced in a series of controlled stages. Plastic tooling plays a vital role in batch production by ensuring precision, cost-effectiveness, and efficiency while maintaining high-quality standards. Unlike mass production, batch production allows flexibility in design changes, reduced tooling costs, and optimized