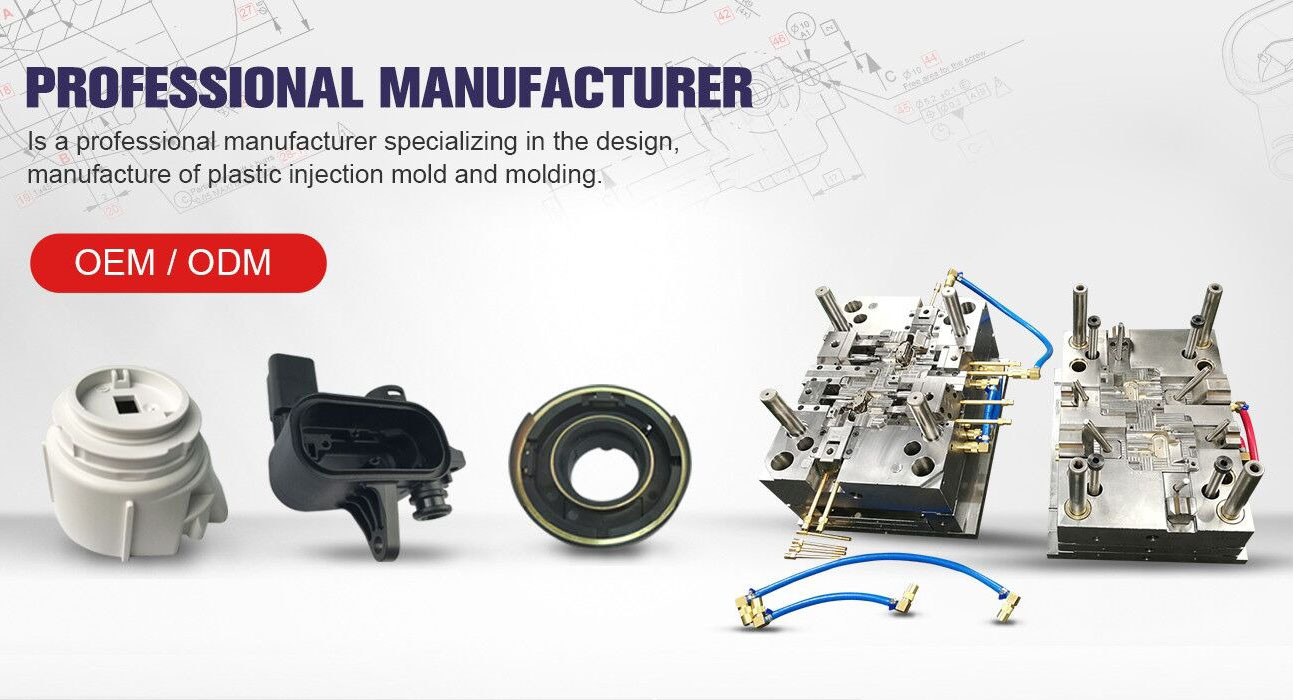

The role of plastic injection molding in new product development

Plastic injection molding

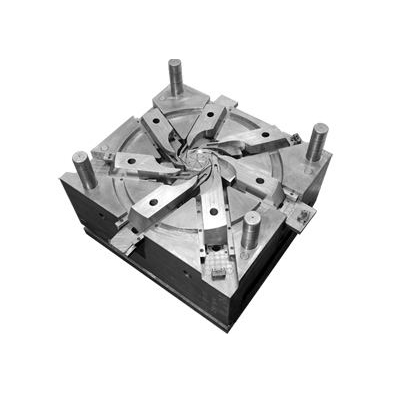

In plastic injection mould, plastic injection molding manufacturers injects molten plastic into the molding cavity of a tool. It compresses under pressure. Moreover, they give enough time to cool, and then ejected as a molded part.

Injection mould is extremely popular process for new product development. You can produce complex shape workpieces in almost any size. The high accuracy and short cycle times predestine the process for economical series production.

Technical basics of plastic injection momould

Plastic injection molding is one of the primary shaping manufacturing processes. in which plastic injection molding manufacturers are creating specific shapes from a shapeless mass by creating material cohesion.

While injection molding is a cyclical process for the production of workpieces with a certain geometry, extrusion is a continuous process for the production of endless profiles. During extrusion, the manufacturers press the molten plastic through a die instead of injecting it into a closed mold.

In plastic injection molding, the raw material - usually in the form of granules - is first heated and plasticized in a screw cylinder. The plastic mass is then goes into the tool with high pressure. This is then come to cool state. Similarly, it is to solidify the melt and finally to remove the finished workpiece.

The most common methods of processing plastics for new product development:

Archetypes

Injection molding

Extrude

Reshaping

Deep drawing

Bending

Put

welding

glue

Because of the high cost of manufacturing injection mould tools, this process is expensive to use economically in prototype and small series production.

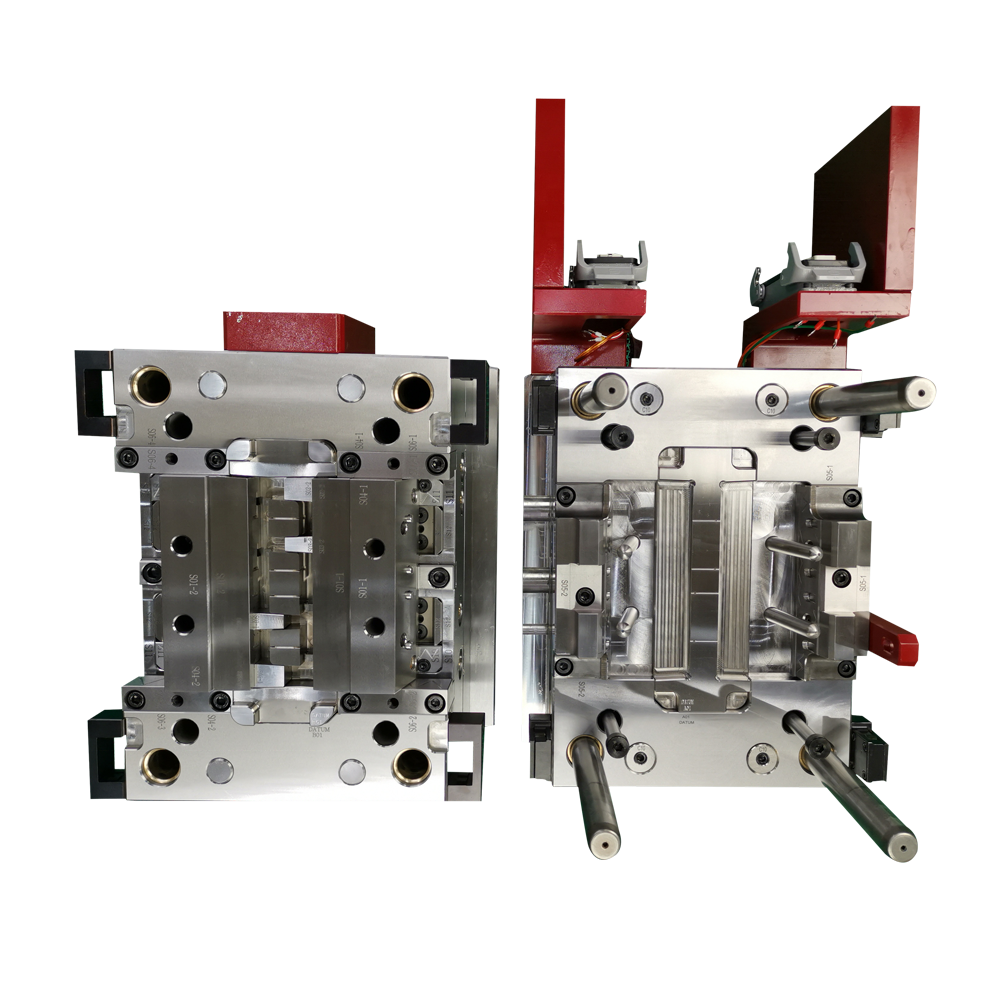

Structure of an injection molding machine

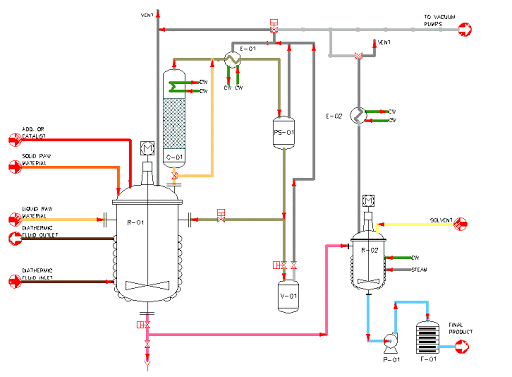

Process flow in plastic injection molding

The injection molding machine coordinates the cyclical process sequence. The determining factors for the settings on the machine are:

Used plastic

Design of the shape (number and size of the cavities, wall thickness)

Machine (locking force, stroke volume)

Special variants of plastic injection molding that require individual process management include:

Over molding of inserted parts

Injection molding of an inserted carrier part

Creation of cavities in injection molded parts

Injection molding of foam parts

Different types of plastic make individual demands on the temperature control of the mold. We are describing injection molding of a thermoplastic here.

Plastic products are used in food, medical, construction and other spheres. Therefore, molding plastic at home can become not only a hobby, but also a profitable occupation. The production of parts for sale or to order is a demanded business, so craftsmen try to make test samples of casting at home.

Preparation of material for casting dies

At home, you can create lids, toys, souvenirs, household items, and other solid items. For the procedure, you need to prepare a number of materials:

- plastic for molding;

- melting tank;

- master model;

- mold;

And other means.

For casting, plastic scrap can be used, which is crushed and melted. However, the melting point is different for all types of plastics, and only one specific type is used to create the workpiece. If you do not follow this rule, the plastic melts unevenly and the parts created from it turn out to be inhomogeneous, bubbly.

Plasticizing and dosing plastic dies

At the beginning of the product oem injection molding cycle, the mold is open and there is a dosed mass volume. The molding compound comes when the plastic granulate derives in from the funnel by a screw and melted.

The material has been plasticized by the action of heat in the heated screw cylinder. Furthermore, the screw transports the material into the front part of the cylinder. Hence, it collects behind the nozzle. Similarly, this creates a dynamic pressure that causes the screw to move backward.

Injecting

When the mold closes and there is sufficient melt between the nozzle and the screw tip to fill the mold, injection can take place. To do this, the axially movable screw presses the plastic compound into the mold. Moreover, the pressure rises to a maximum value during filling and then gradually falls.

Press down and cool down

The pressure has been maintained in order to be able to compensate for the shrinkage of the solidifying melt. The cushion of mass remaining in front of the screw tip can flow into the mold. This helps avoid common mistakes in injection molding. Sink marks and blowholes. Now you can cool in order to accelerate the cooling process of the molded part.

Demoulding and ejection for product oem

Now the tool is easy to open to eject the solidified molding. The workpiece falls out of the mold or is removed by a handling device. The sprue that does not belong to the molded part can then be removed manually or automatically.

Which materials can be processed?

Plastic injection mould is suitable for processing all types of plastics:

Thermoplastics

Thermosetting plastics

Elastomers

Thermoplastic elastomers

However, we should note that that the different polymers require different temperature control of the tool. Injection molding of thermoplastic materials, especially polyethylene, is of the greatest economic importance.

THERMOPLASTIC INJECTION MOULD FOR PRODUCT OEM

Thermoplastic injection mould is the basis for all other injection molding processes. It is very good for new product development or product oem. And it is very famous plastics processing process.

Injection molded parts are easy to manufacture for plastic injection molding manufacturers. The processed thermoplastics are modified by additives and fillers for injection molding processing and later use. This includes very hard inorganic fillers such as glass spheres or, very often, glass fibers.

THERMOSET

Duroplasts are glass-like, hard polymer materials which, after they have hardened, can no longer be deformed by heating or other measures. This material is common to use for insulation and construction. Moreover, CNC processing is common to use to modify thermosets.

ELASTOMERS SURFACE FINISHING AND PLASTIC DIES

As a customer, you may face with the question of why and when elastomer seals should refine at all.

Whether for expanding functions and solving problems in general, in order to avoid stick-slip, in dynamic use to reduce friction and wear, or for assembly problems: Elastomeric surface finishing offers numerous advantages in many specific applications.

Injection molding comes on the process of forced filling of the working cavity of the mold. Moreover, it comes with melt and the subsequent formation of the casting under the influence of the pressure of the press piston. The main methods plastic injection molding manufacturers use in this technology are:

Injection

A dose of the melt is accumulated in the cylinder and is injected into the mold under high pressure in a short time interval. The method makes it possible to obtain parts of complex configuration from plastics of various types;

Intrusive

the melt is fed into the mold by rotating the worm, which in the extrusion mode fills the mold, stops and after the temperature shrinkage of the melt by axial movement feeds the mold. The method is focused on obtaining products with simple geometry;

Injection-press

the pressure on the melt in the mold is carried out both by the injection force and by means of the press of the clamping unit. The technology is common to use to obtain parts with a significant surface area;

Gas injection method for product oem

Molten raw material injects and fills the mold by 70–95%, and a gas mixture is supplied there under pressure (through a nipple or nozzle in the mold), increasing the volume of the polymer. The method allows you to save raw materials, reduce the volume of rejects and reduce the cost of production;

Co-injection

Generally, it involves the use of nozzles of a special design (dividing heads) and makes it possible to obtain products with several layers, as well as with color separation - partial or complete;

Multilayer casting

Basically, it involves the use of two or three injection units for plasticizing different types of raw materials. The method allows you to get products consisting of several colors, different types of plastics, etc .

Sandwich casting and plastic injection mould

It provides for alternate or simultaneous feeding into the injection mold of two polymer melts from separate plasticizers. The outer shell forms from the first material. Similarly, the inner volume of the product comes with the second.

Casting in multicomponent molds

Basically, injection units work according to the traditional scheme, and the features of the product depend on the device of the mold. It comes with two gating systems coupled with the injection units. The injection units work independently. The technology provides products with a hybrid design or with a clear color separation. Rotary casting is a variation.

Generally, the use of one method or another is due to the existing production tasks. High-quality implementation of one technology or another is possible. Only professional plastic injection molding manufacturers are common to hire.

The essence of the metal injection molding process

A fairly common process in new product development, plastic injection mould is common.

A high pressure is good to apply to the material in the form of a casting - about 8-700 MPa. And due to this effect, the metal takes the shape of a casting in a short time. Hence, this way you can create literally any shape out of metal.

By the way, non-ferrous metal alloys are fit to a similar process, that is, metals based on:

- zinc

- aluminum

- Copper

- Magnesium

- tin, lead and others.

This is due to the fact that these metals have the lowest melting point and quickly change their shape when exposed to heat.

The weight of the processed products can range from a couple of grams to several tens of kilograms.

Application of metal pressure casting technologies and plastic dies

Metal injection molding is quite common in the production of the following parts and plastic dies:

Automotive - carburetors, aluminum blocks and other things,

Plumbing elements,

Household appliances, including vacuum cleaners, washing machines, irons, and small appliances

Computers.

Generally, the metal casting process itself is quite simple. Moreover, the molds that are common to use for metal blanks are usually made of steel. Similarly, some molds have special ejectors and moving segments to create holes or cavities in a future product.

For metal injection molding are common to use:

special machines with a hot chamber,

Machines with a cold metal pressing chamber.

Cold chamber machines for plastic die product oem

Generally, in these chambers, molten metal pours into the pressing chamber. Here, under pressure, the metal enters the mold, which consists of three moving parts.

After the metal has solidified, first the mold opens. Similarly, the inner core removes to create a cavity. And the ejectors help to separate the product from the press. The pressure when using a cold bale chamber is about 40-100 MPa.

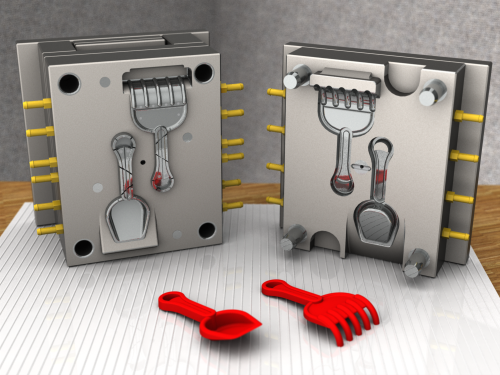

Self-made plastic injection mould

The production of plastic products without a forming vessel is impossible. You can do it yourself, and silicone is best suited for these purposes. It can be either coating or pouring, both are suitable. The main thing is that the elongation coefficient is at least 200%. It is worth paying attention to the level of viscosity. Furthermore, the smaller it is, the more detailed the mold will be.

To make a blank, you need to have a master model - a sample for future products. Subsequently, plastic injection mould manufacturers can create it from plaster, wood, plasticine, printed on a 3D printer, or using an existing part.

Stages of making a mold for casting:

- Coat the master model with a thin layer of grease, for example, lithol.

- Place in the prepared formwork and fill with silicone.

- Or brush over with a brush if a coating silicone is selected.

- Wait about 8 hours until the material hardens.

- Remove the form from the formwork, make a hole for pouring.

- Cut into 2 equal parts, extract the model.

In this way, we obtain a collapsible mold. Hence, it is suitable for casting symmetrical plastic products. But you can also make an integral form for workpieces that are simple in design. Plastic injection mould manufacturers make it from paraffin, which is filled with plaster. After hardening, the paraffin is melted out of the mold by slowly boiling it.

Silicone casting process

When the mold is made and the material is prepared, you can start molding the plastic at home. At the first stage, the workpiece is thoroughly clean of possible debris and lubricated inside with a lubricant. For better separation, its edges should be greased with soapy water. Then the two halves of the detachable form are connected and fastened with tape or elastic bands.

Hot chamber machines for plastic injection mould

This equipment does not require manual pouring of molten metal into the mold. Furthermore, the metal fills the mold by gravity. After that, an automatic signal triggers, and the piston acts on the red-hot alloy.

Through special channels under pressure, the metal passes into the cavity. And there it takes on a crystalline form. Similarly, the process is fully automatic. Therefore after the timer comes with the time necessary for the formation of the casting, the mold is opened, and the part itself is pulled out by pushers.

It is worth noting that the quality of castings largely depends on various factors underlying metal casting machines, among them:

choice of alloy;

casting design;

ventilation system;

alloy temperature and shape stability;

Evacuation of the mold

Generally, it is necessary to prevent the appearance of porosity in the cast metal, which significantly reduces its strength characteristics.

The method of metal injection molding is quite effective. Moreover, it is easy to use to obtain high-precision product dimensions, precise configuration and shape. Hence, it provides ideal relief and high surface quality.

In addition, the advanced metal injection molding machines have high productivity. Generally, conventional equipment can produce 3-50 castings in one minute. And when using a modification with advanced capabilities, more than 15 parts can be produced in one fill.

It is also important that the metal poures into a mold at a temperature 10-25 degrees above the melting point of the metal. Injection molding is common to use to produce parts with a minimum wall thickness of 0.8 mm.

What are the disadvantages of plastic injection mould

The disadvantages of this equipment include some nuances associated with the complex configuration of the product. When metal removes from the mold, damage can occur.

In addition, inconveniences arise when it is necessary to cast a product of large thickness. The alloy hardens faster and stronger with a minimum casting thickness. That is why most equipment has a limitation on the thickness of the casting.

Why it is important to hire plastic injection molding company?

The life of a modern person today is almost impossible to imagine without plastic products. These materials are common to use in the manufacture of many household items. And due to their physical properties, they allow you to create products of the most incredible shapes and sizes.

Plastic items are common to use almost everywhere - in medicine, in manufacturing, in electrical engineering, construction, and shipbuilding and automotive.

How does plastic injection mould help in new product development?

Plastic injection mould is an effective and widely common method of making all kinds of plastic items. This method allows you to achieve high accuracy of the finished product of any complexity, regardless of its design parameters.

How is the process of plastic injection molding?

The whole process we can divide into two stages:

- preparatory and

- The main stage ofthe injection molding process includes the following points: plastic feeding, mold cooling and finished product delivery.

The professional plastic injection molding manufacturers will take into account all your wishes. And, thanks to their experience and knowledge, will make an order that fully meets all the requirements as soon as possible.

Calculation of the cost of plastic injection molding manufacturers services

When calculating the cost of the injection molding service, the following factors are taken into account:

The complexity and parameters of the product.

Order volume: the higher the circulation, the lower the cost per item.

Terms and conditions of delivery.

Advantages of the plastic injection mould method

- Using the injection molding method, you can get a part of any size and complexity. Furthermore, the design of the manufactured mold takes into account the smallest details, the many bends and holes of the planned product.

- The finished product does not need revision, since all the nuances were taken into account during the preparatory stage at the time of testing.

- The high-pressure injection mold created before production has great strength. However, do not lose sight of the fact that it has a certain resource, which is selected based on the client's requirements. This resource is limited by the amount of form closing / opening.

- The presented method is successfully used in large-scale production.

Practical significance of new product development with plastic injection mould

Thanks to the high-pressure plastic injection molding method, almost any plastic product is easy to make:

Kids toys

Plastic packaging, caps, lids, etc.

Housings for radio electronic equipment

Medical Equipment Enclosures

Automotive components

Household Appliance Parts

Product oem with plastic injection mould at home

Plastic products are common in food, medical, construction and other spheres. Therefore, new product development with plastic injection mould at home can become not only a hobby, but also a profitable occupation. In addition, the production of parts for sale or to order is a very famous business, so plastic injection molding manufacturers try to make test samples of casting at home.

Preparation of material for casting

At home, you can create lids, toys, souvenirs, household items, and other solid items. For the procedure, you need to prepare a number of materials:

- plastic for molding;

- melting tank;

- master model;

- mold;

And other means.

For casting plastic dies, plastic scrap is very common to use, which is crushed and melted. However, the melting point is different for all types of plastics, and only one specific type is common to use to create the workpiece. If you do not follow this rule, the plastic melts unevenly and the parts created from it turn out to be inhomogeneous, bubbly.

In everyday life, it is easier to use ready-made mixtures with plastic dies, for example, liquid plastic or epoxy resin. The material does not require melting. Moreover, you can prepare it quickly and set and the products from it are not inferior in quality to their counterparts. As an alternative, AKR-7 powder is also suitable. Similarly, it requires mixing with a solvent. It takes longer to prepare plastic from it, but the result is pleasing.

However, if, nevertheless, a decision is good to melt scrap, for example, old boxes, buckets, dishes, safety precautions should be followed and casting should be carried out in ventilated, non-residential areas, since plastic vapors are toxic and dangerous to humans.

Product oem development with plastic injection mould mold is simple

The product oem of plastic products without a forming vessel is impossible. You can do it yourself, and silicone is best suited for these purposes. It can be either coating or pouring, both are suitable. The main thing is that the elongation coefficient is at least 200%. It is worth paying attention to the level of viscosity. The smaller it is, the more detailed the mold will be.

To make a blank, you need to have a master model - a sample for future products. We can easily create it from plaster, wood, plasticine, printed on a 3D printer, or using an existing part.

Stages of making a mold for casting:

- Coat the master model with a thin layer of grease, for example, lithol.

- Place in the prepared formwork and fill with silicone.

- Or brush over with a brush if a coating silicone is selected.

- Wait about 8 hours until the material hardens.

- Remove the form from the formwork, make a hole for pouring.

- Cut into 2 equal parts, extract the model.

In this way, a collapsible mold is obtained, which is suitable for casting symmetrical plastic products. But you can also make an integral form for workpieces that are simple in design. It is made from paraffin, which is filled with plaster. After hardening, the paraffin is melted out of the mold by slowly boiling it.

Silicone casting process

When plastic injection mould material is ready, you can start molding the plastic at home. At the first stage, the workpiece is thoroughly cleaned of possible debris and lubricated inside with a lubricant. For better separation, its edges should be greased with soapy water. Then the two halves of the detachable form are connected and fastened with tape or elastic bands.

This method is very common among plastic injection molding manufacturers.

In a separate container, two-component plastic ready in another way, depending on what is selected as raw material. At this stage, we add plastic dies to the material. Liquid plastic polymerizes in 10-15 minutes, so it's worth working quickly.

The finished material poures in a slow stream into the mold, so that the infusion hole also fills. After hardening, the plastic shrinks and the product takes on the required shape. After waiting for the time indicated in the characteristics, for liquid plastic it is 15 minutes, you can remove the model.

Powder casting

To prepare the plastic, AKR-7 powder is mixed with a solvent to form a dough. The proportions are indicated on the packaging. The resulting raw materials are poured into molds and wait up to 30 minutes, and then tamped with a stick through the casting hole until at least 3-5 mm are free from the upper edge of the mold.

The casting hole must be closed and tightened, for example with a clamp. The mold is placed in water at room temperature and brought to a boil. The workpiece is cooked over low heat for about 40-45 minutes and after turning off the oven it remains in water for another 20 minutes. After the material has cooled, we can detach the mold can and the homemade plastic product is easy to remove.

Home Manual Casting Machines

Bench-top machines can be good to use for small-scale casting of plastic parts. It is a compact piece of equipment that will fit in any private workshop or garage. It is possible to pour plastic on them in single or multi-place forms, depending on the size and serial production. The units differ from industrial equipment only in small dimensions. The bench press is suitable for all polymers and is easy to operate.

Stages of casting at home on the machine:

- Installation of the device and the injection nozzle.

- Setting the mold and lubricating it with silicone;

- Loading the polymer into the hopper;

- Heating and stirring the material with a screw;

- Pouring raw materials into molds;

- Waiting for cooling;

- Removing the plastic part.

Also in everyday life, welding extruders can be good to hold together plastic parts to produce more complex products.

Conclusion

New product development is possible with plastic injection mould. Furthermore, you can do it with your own hands individually, as entertainment, or as a one-time need.

For this, homemade forms and improvised means or specialized, home equipment are suitable. It is more profitable to entrust mass casting to specialists, since this requires expensive, bulky equipment. And you will need the work of experienced plastic injection molding manufacturers.