Automotive mold is an indispensable tool in the plastic injection process, useful for the growing industry of plastic products in the world.

We are a quality plastic injection mold processing unit according to the orders of domestic and foreign partners. We will work with you to learn more about what plastic injection molds are and their role in the article below.

What is plastic injection mold?

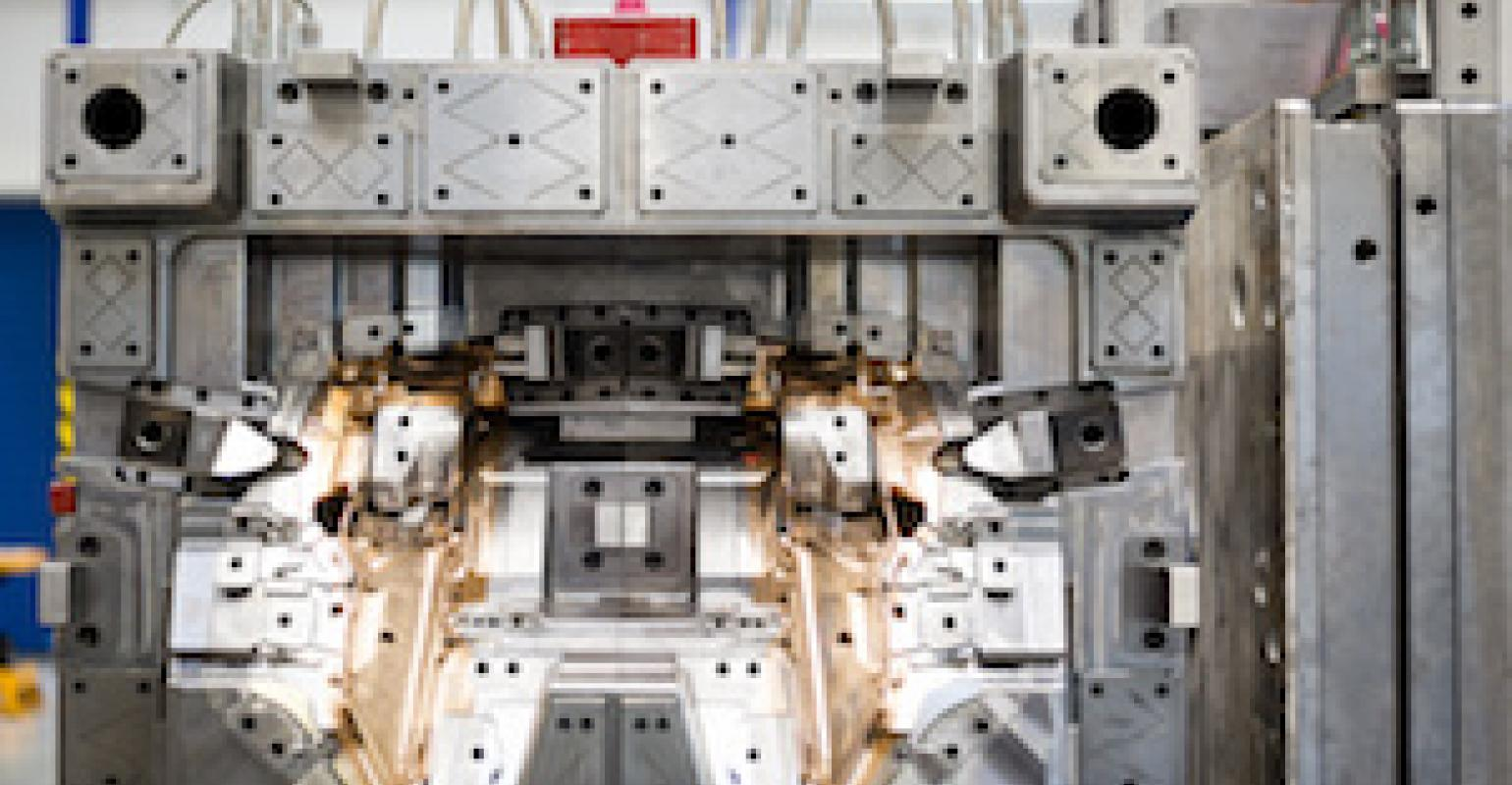

Plastic injection mold is a tool common to shape plastic products; plastic injection molds are good to design to be common for a required number of cycles. In other words, the plastic injection mold consists of many parts assembled together, after the plastic injects into the mold and cooled, the product will be ejected.

Importance of automotive injection mold its size

Automotive mold is an extremely important component in the plastic production line. It acts as a template to create plastic products with the right design as required. The size and structure of the plastic injection mold depends on the size and characteristics of the product. Depending on the number of products, we choose the most suitable and effective mold.

The effect of plastic injection mold

Plastic injection molds are common in the production of structural parts of many products such as household appliances, electrics, electronics, cars, motorcycles, etc. Plastic injection molds are tools for the production of thermoplastic products. It comes with finishing plastic products even when they have a complex structure.

By using different types of plastic injection molds of different sizes and complexity it is possible to create different products.

Raw plastic after in the injection molding machine injects into the automotive mold, the formed product ejected after cooling and solidifying.

The important role of plastic injection mold

Plastic injection mold allows the production of real injection material, can check the tool structure obtained from the mold process. Thereby confirming the reliability of the tool structure is for optimizing the injection port position.

Plastic injection mold processing technology contributes significantly to reducing mold production costs. But still it meets customer requirements for the number of parts for production.

After the required parts are made, it is still possible to continue making plastic injection mold specifications changes at a lower cost for the next round of testing.

Automotive mold produce products that can meet the requirements of tight tolerances, superior mechanical properties and high polished surface quality.

What is the plastic injection mold polishing?

Plastic injection mold polishing is an extremely important stage in plastic injection mold making to create ordinary plastic products with high surface gloss. With different plastic products, the requirements for the surface gloss of plastic molds are different.

Technical requirements for plastic injection mold polishing

General requirements

Mold surface treatment ensures quality for later processing stages.

Understand the factors affecting mold polishing: polishing technique for each type of mold, steel quality, heat treatment.

Conduct plastic injection mold polishing in less dusty places and select polishing tools suitable for each detail and part in the automotive mold.

Polished surface tolerances shall be within the allowable range specified in the original engineering drawings.

Parts and details of plastic injection molds of optical plastic products, CDs will require much higher accuracy in polishing techniques.

Technical requirements for plastic injection mold polishing

Choosing the polishing method of plastic injection mold will make the polishing job extremely simple but still ensure product quality. You can choose one of the following six methods to polish plastic injection molds.

1. Mechanical polishing

The Mechanical polishing of plastic injection molds uses cutting and removal of protrusions to obtain a smooth surface. Mechanical polishing is mainly done manually and usually using grinding wheel, wool wheel, sandpaper... For special parts with propeller surface need to use turntable, the parts in the automotive mold if high surface quality is required, ultra-precision polishing will be required.

What is automotive mold polishing?

Ultra-precision polishing can achieve a surface roughness of 0.008μm, which is the highest precision polishing method, commonly common for optical lens injection molds. Ultra-precise polishing uses a polishing fluid containing a special abrasive that is pressed against the surface of the workpiece and machined at a high rotational speed.

2. Chemical polishing

Chemical polishing is a method of using a chemical solution to abrade the protrusions in the mold surface to obtain a smooth surface. So Chemical polishing will produce an overall surface roughness of 10μm in the automotive mold product.

Main advantages of chemical polishing method:

Simple device use

Good polishing even for workpieces with complex shapes

It is possible to simultaneously polish different molds but still bring high efficiency.

3. Electrolytic polishing

Electrolytic polishing works on the basic principle that is to smooth the surface by selectively dissolving small protrusions on the surface of the part or mold cavity. The electrolytic polishing process has the outstanding advantage of eliminating the effect of fine reaction.

Electrolytic plastic injection automotive mold polishing process consists of two steps:

Step 1: Macro leveling: Solubility spreads to electrolytic material, fine-tuning rough surface geometry, Ra>1μm.

Step 2: Micro plane: anodizing, increasing surface brightness, Ra < 1μm.

4. Ultrasonic polishing

The work piece is immersed in an abrasive solution and comes in the same ultrasonic field. For ultrasonic oscillation, the abrasive conducts grinding and polishing on the surface of the work piece. The small ultrasonic machining force will not cause deformation of the work piece, but having limitations in tool making and installation is difficult.

Ultrasonic polishing is easy to combine with chemical or electrolytic methods.

5. Liquid polishing

After using automotive mold final product polishes. Liquid polishing is a method of using a liquid comes in a high-speed flow condition to achieve the purpose of polishing on a washed surface. Liquid polishing includes specific sub-polishing methods:

- Abrasive spray polishing

- Liquid spray polishing

- Hydrodynamic grinding polishing

In it, the hydrodynamic grinding polishing comes by the hydraulic fluid carrying the abrasive medium to meet through the work pieces surface,