In the realm of plastic manufacturing, effective mold design is crucial for achieving high-quality, cost-effective, and efficient production processes. As a manufacturer partnering with ACE, a leading expert in plastic injection molding, understanding the key design tips and best practices can greatly impact the success of your project. This blog aims to provide practical insights, guidelines, and expert advice for optimizing your plastic injection mold design.

Designing for Manufacturability:

Designing a mold with manufacturability in mind is essential for streamlining the production process and minimizing costs. By adhering to the following design tips, you can ensure a smooth manufacturing experience:

1. Simplify Part Geometry: Complex part geometries can increase the complexity and cost of mold design and production. Simplifying the geometry of your plastic parts can lead to more efficient molding processes and reduced cycle times.

2. Incorporate Proper Draft Angles: Draft angles are essential to facilitate easy ejection of the molded parts from the mold cavity. Aim for draft angles of at least 1-2 degrees, depending on the part's size and material, to prevent part damage and ensure smooth ejection.

3. Optimize Wall Thickness: Maintaining consistent wall thickness throughout your part design minimizes issues like sink marks, warping, and inconsistent cooling. Aim for uniform wall thicknesses to enhance part strength and reduce manufacturing defects.

Reducing Defects and Enhancing Part Design:

Achieving high-quality molded parts while minimizing defects requires careful consideration during the mold design phase. Implement these best practices to improve part design and reduce manufacturing flaws:

1. Gate Placement: Proper gate placement is critical to control the flow of molten plastic into the mold cavity. Opt for gate locations that minimize visible gate marks and maximize part strength while ensuring even filling and proper packing.

2. Venting: Adequate venting is crucial to allow air and gases to escape during the molding process, preventing voids and surface defects. Incorporate well-designed vents in the mold to ensure optimal part quality and reduce the chances of short shots.

3. Incorporate Ribs and Fillets: Ribs and fillets can enhance part strength and rigidity while reducing material usage. Intelligently adding ribs to the design can prevent warping and ensure dimensional stability, while fillets help to avoid stress concentration areas and potential part failure.

Improving Cycle Time and Efficiency:

Efficiency in plastic injection molding is a key factor in achieving cost-effective production. Consider these tips to optimize cycle time and enhance overall efficiency:

1. Gate Size and Design: The size and design of the gate impact the filling and cooling phases of the injection molding process. Optimize gate size and shape to ensure efficient material flow, minimal pressure drop, and balanced filling of the mold cavities.

2. Cooling System Design: Proper cooling is essential to achieve consistent part quality and minimize cycle times. Incorporate an optimized cooling system with uniform cooling channels to ensure even heat dissipation and reduce cooling time.

3. Parting Line Design: A well-designed parting line can simplify mold assembly, reduce flash formation, and improve overall efficiency. Minimize the complexity of the parting line while maintaining proper alignment to streamline the mold design and manufacturing processes.

Revolutionizing Manufacturing: Unveiling the Power of Plastic Injection Mold Design

Manufacturing that centers around precision, efficiency, and affordability is highly complex – but plastic injection mold design simplifies the situation. This revolutionary process has revolutionized product creation, providing manufacturers with the ability to craft intricate designs with maximum speed and precision.

1. Automotive Industry: Driving Innovation

The automotive industry has embraced plastic injection mold design to drive innovation and meet evolving consumer demands. From intricate dashboard components to exterior body parts, the ability to create complex geometries and optimize material usage has revolutionized the manufacturing process. ACE, with its expertise in mold design, partners with automotive manufacturers to deliver lightweight, durable, and aesthetically pleasing parts that enhance vehicle performance and fuel efficiency.

2. Consumer Electronics: Shaping the Future

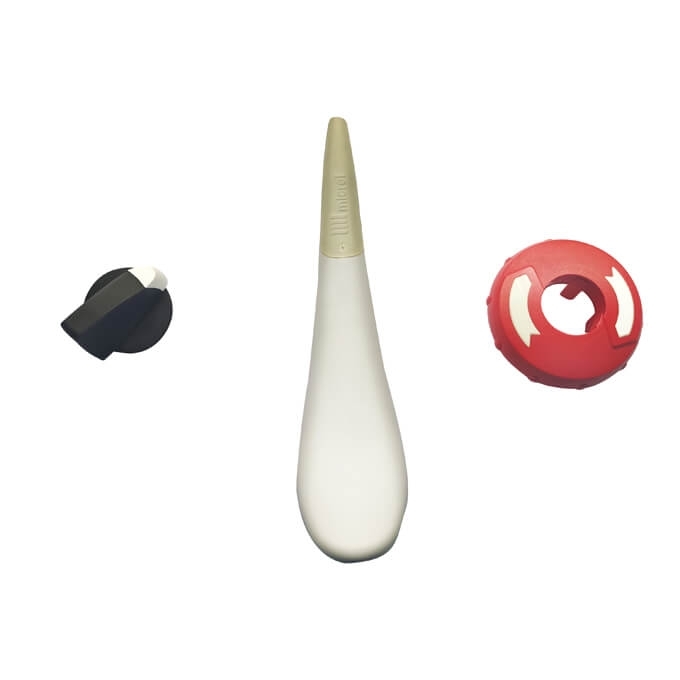

In the fast-paced world of consumer electronics, plastic injection mold design plays a pivotal role in shaping the future. The demand for sleek, ergonomic designs combined with functional precision requires advanced molding techniques. ACE collaborates with leading electronic companies to create molds that enable the production of intricate casings, connectors, and internal components, ensuring seamless integration, durability, and optimal performance.

3. Medical Devices: Precision and Safety

When it comes to medical devices, precision, safety, and reliability are non-negotiable. Plastic injection mold design ensures the production of intricate, sterile, and biocompatible components. ACE's expertise in mold design enables medical device manufacturers to develop instruments, implants, and diagnostic equipment with unmatched accuracy, enabling healthcare professionals to provide better patient care.

4. Packaging Industry: Efficiency and Sustainability

The packaging industry relies on plastic injection mold design to optimize efficiency and sustainability. By designing molds that create lightweight yet sturdy packaging materials, ACE helps manufacturers reduce material waste and transportation costs while maintaining product integrity. This innovation has a direct impact on reducing environmental footprints, making it a win-win for businesses and the planet.

ACE: Revolutionizing Plastic Injection Mold Design

1. Customized Solutions for Diverse Industries

ACE stands out in the field of plastic injection mold design by offering customized solutions tailored to the unique requirements of various industries. Whether it's automotive, electronics, medical, or consumer goods, ACE collaborates closely with its clients to understand their specific needs. By integrating their expertise in mold design, engineering, and material selection, ACE ensures that the final mold design meets the highest standards of functionality, durability, and cost-effectiveness.

2. Innovative Design Techniques

ACE prides itself on its innovative design techniques that optimize the plastic injection molding process. One such technique is the application of conformal cooling channels. Unlike conventional straight cooling channels, conformal cooling channels are designed to follow the contours of the mold, maximizing cooling efficiency and reducing cycle times. This innovation significantly improves productivity, minimizes part defects, and enhances overall mold performance.

3. Design for Manufacturability (DFM) Approach

A key aspect of ACE's success lies in its design for manufacturability (DFM) approach. By involving mold designers early in the product development phase, ACE ensures that the design is optimized for efficient and cost-effective manufacturing. Through the DFM approach, potential design issues, such as part draft angles, undercuts, and wall thickness variations, are identified and addressed early on, minimizing the risk of costly modifications during production.

Conclusion:

Designing an effective plastic injection mold is a crucial step toward achieving successful and efficient production processes. By following the design tips and best practices outlined in this blog, manufacturers partnering with ACE can enhance manufacturability, improve part quality, reduce defects, and optimize cycle times. With a focus on optimizing the plastic injection mold design, you can unlock the full potential of injection molding and maximize the success of your projects.