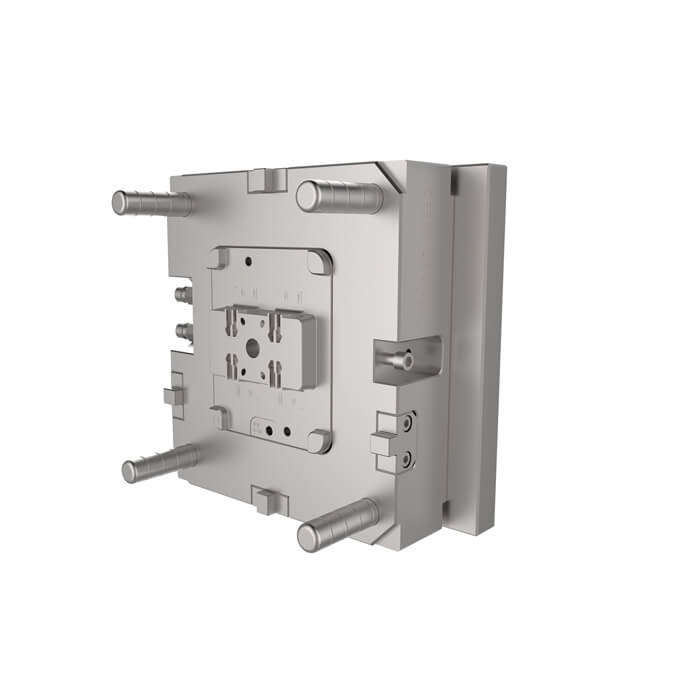

Plastic Injection Mould Components

The use of plastic injection mould components for manufacturing is growing in popularity, as it offers many advantages over traditional manufacturing methods. Plastic injection mould components can be used to create complex shapes, precise details, and even intricate patterns. They are also less expensive, faster to produce, and require less labor than other types of manufacturing.

ACE provides plastic turnkey solutions from innovative concept design to reality. ACE can meet our customer's most challenging demands through the combined use of international state-of-the-art equipment and traditional Tool-making knowledge. With our collective experience, the ACE team designers and toolmakers are constantly striving to refine and perfect our skills. Our superior performance is based on the successful completion of every step. "For the first time"

- Plastic processing with Medium and large processing windows

- All thermoplastics, including fillers and reinforcement materials

Benefits of Plastic Injection Mould Components

Plastic injection mould components are one of the most efficient and cost-effective ways to create custom-made parts for any application. They are versatile, lightweight, and durable, making them suitable for a variety of uses. In addition, plastic injection mould components are cost-effective because they require fewer man-hours and less material than other manufacturing processes.

Speed: Plastic injection moulding is a manufacturing process used to produce components of various shapes and sizes. The process involves injecting molten plastic material into a mould cavity and allowing it to cool and solidify. To achieve the desired shape and size of the components, different parameters such as temperature, pressure, and speed of injection must be carefully controlled

Design Accuracy: The accuracy of the injection moulded parts depends on several factors, including the geometry of the mould and the injection moulding process parameters. The accuracy of the injection moulded parts is important for the quality of the final product.

Quality: The quality of plastic injection mould components is of utmost importance when it comes to producing plastic parts. To ensure that the parts produced are of the highest quality, it is important to use only high-quality mould components. This includes the mould base, mould inserts and other components used in the injection moulding process

We can build the automotive parts as follows:

- Seatback

- Deckled trim

- Inside door handle

- Door trim

- Engine parts

- Roof parts

- Lighting parts

- Mudguard parts

- Airbags

- Air conditioner components

Why Should You Work With ACE Group?

1. We have a highly experienced in-house design and development team. We are very comfortable and skilled in dealing with our international clients.

2. We provide OEM/ODM services to all types of customers and have professional customer support and project management teams on hand 24 hours a day, seven days a week.

3. We have a strict quality control system in place to ensure that our products are of the highest quality, that we provide the best service, and that our prices are competitive.

4. Samples are delivered quickly and are always available for quality inspection.

5. Design ability: create designs based on customer specifications.

6. We transparently collaborate with clients and deliver goods on time.

| Brand Name | ACE |

| Model Number | ACE00018 |

| Process Servicing | Injection moulding for automotive plastic injection parts |

| Shaping Mode | Over Moulding, Insert Moulding |

| Standard Parts/Cylinders | DME / HASCO / PROGRESSIVE / MISUMI / Parker / HP / Merkle |

| Surface Requirement | Texture EDM SPI Chrome Coating |

| Ejector System | Pin / Air valve / Stripper plate |

| Injection System | Cold runner / Hot runner |

| Injection Moulding Process | Horizontal Injection |

| OEM/ODM | Acceptable |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |