Plastic Molding Manufacturing Process

Molding of plastic by the Plastic Molding Manufacturer is one of the most inexpensive technologies. This has unerringly changed the way the world perceives plastic molding. It is a timeworn technology that lay dormant for quite some time because people never knew the full range of benefits that come with it.

But now, Plastic Molding Manufacturer embeds the process of injection molding to make/shape plastic. It is an effective way of manufacturing plastic moldings. By far, manufacturing plastic moldings via the injection molding process is the best. It variably increases productivity plus many manufacturers are ditching the old methods and adopting injection molding.

Earlier, the plastic molding process was insignificant. But manufacturers have found its true market and a well-deserved niche for its marketplace. A quality mold carries a great significance in the life of plastic. A Plastic Molding Manufacturer has understood this and is trying to cope with the rapid increase in its demand. The success it has gained is worth it.

You May Also Read: The Main Components of China Plastic Injection Molding

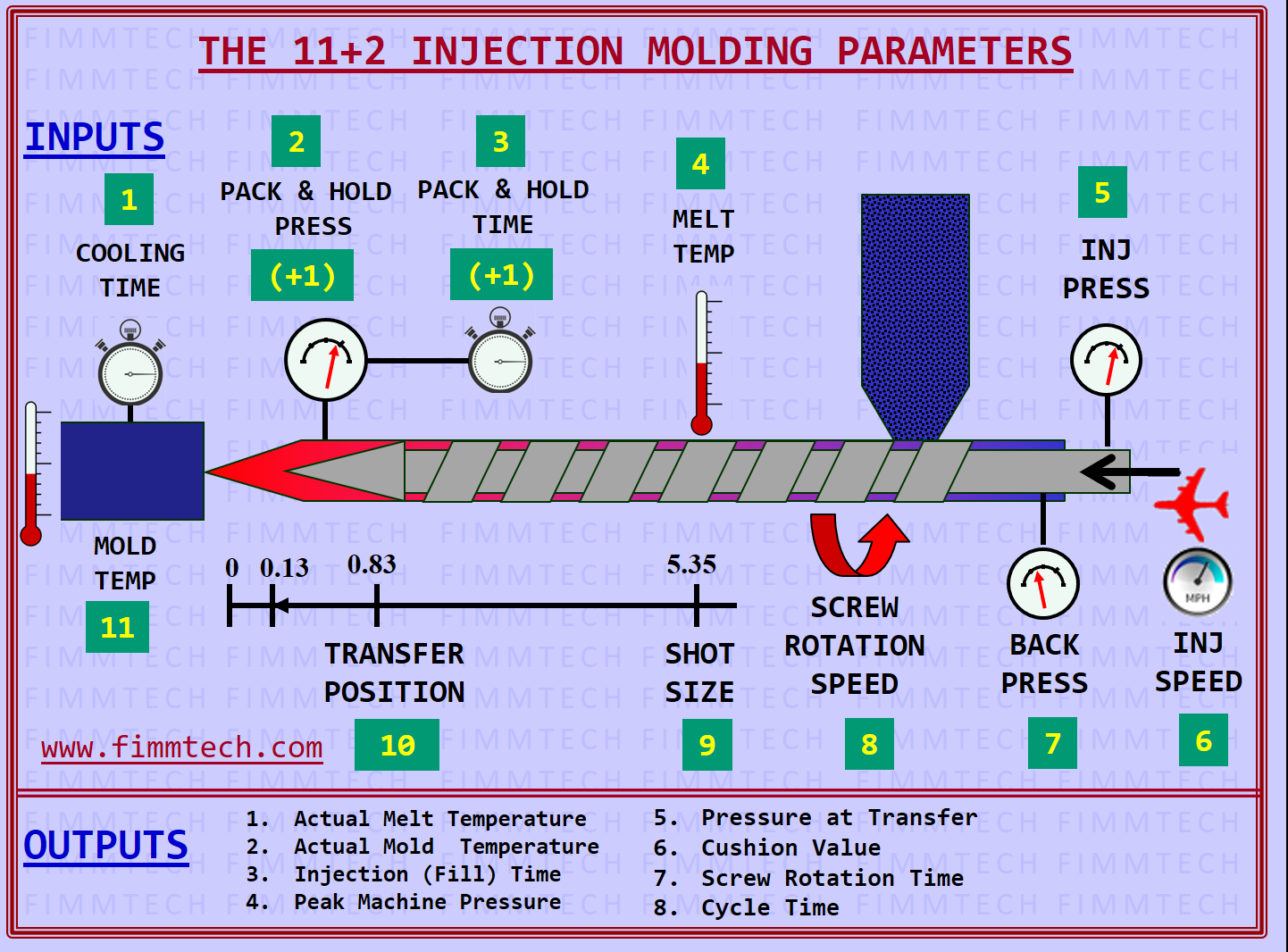

Moreover, the molding manufacturers are finding new ways and on the other hand trying to refine the existing injection molding process by capturing the right parameters that optimize production. Manufacturing viable plastic moldings are the prime goal here.

It is better yet very beneficial to keep possible checks on the results of Plastic Molding. This helps the manufacturers in keeping up the pace with the demands of the production line. It is a great way to keep the competitors at bay and clients within the loyalty circle. The daily basis change in manufacturing methods can be quite challenging. There should a fool-proof way of channeling the process controls to ensure optimized quality.

There should be a conduction of a proper check and balance system for making the plastic molds. This absolutely needs to be done to ensure that the quality matches the demand. This is where prototype development plays a significant role. A prototype helps in making an initial or virtual model test whether it gives the desired results or not.

Before producing the actual batch, this is a very helpful step. You can make the changes in the prototype model rather than the whole production itself. It is a platform for client and manufacturer satisfaction. Plus this also puts a great reputation out in the world.

Optimization of Parameters to Manufacture Plastic Molds

Prototype testing is really important before manufacturing Plastic Molds. It lays the basic groundwork for the model on with the molds will establish. This is considerably a great way to ensure that the right parameters are guided into the system. The right parameters carry significant weightage to give optimized results.

For this purpose, parameters need to control the optimized values, optimize temperature, balance machine and oil temperature, and optimize pressure, control shrinkage, and minimize the stress generated in the mold. These parameters are really crucial for the productivity line.

Injection plastic molding has proven itself to be the finest manufacturing way. It can develop easy yet complex plastic moldings to support client demands. It is not easily achievable as said. The optimization of injection molding depends on multiple factors. It has to go through several processes that work on specific parameters otherwise the result might vary and that too in a bad way.

This set of parameters are not just random are fed into the machine. They are a collection of well-defined, tested, and verified parameters. They inject specific values in the system to achieve quality output. It becomes imperative that the results the manufacturers achieve will be top-notch. Of course, after working with the set of certified parameters it impossible not to give optimized results. Moreover, this works in the interest of the manufacturers to follow the designated parameters for each injection molding process.

Setting the Optimized Injection Molding Parameters

The Injection Molding Process is a complex labyrinth of the process that works around achieving the right plastic moldings. It is mandatory to score good results every time. There are some restrictions, methods, and stages of leveling the right parameters.

The parameters need to be followed to the dot. This is because even if there is a minute change the results can vary hugely thus, giving results that the client might not like.

Setting the Temperature Parameters for Injection Plastic Molding

Temperature parameters play a major role in Injection Plastic Molding. When the temperature is low, it can prevent the material from molding and hinder the fluidity of the material flow. This can make the transition process difficult and time-consuming.

On the other hand, if the temperature exceeds the set levels, it can destroy the mold shape and rendering the mold useless. The over-heated material transfer can destroy the silhouette of the desired mold. Hence, setting the right temperatures for injection plastic molding is dire.

Moreover, the mold should stay at a normal consistent temperature that supports the injection molding fluidity. There is a proper study to understand the temperature requirements for different injecting materials too.

Setting the Optimized Values for Back and Front Pressure of Injection Plastic Molding

The process consists of multiple small procedures that add up to achieve a common goal. When the materials inject with the help of back pressure it can immediately slow down the whole process. This can become a risk when the input pressure is minimal.

It is always preferable to introduce high values of pressure even at the back end so that the pressure consecutively works to achieve the goal faster. It limits the number of restrictions a slow pressure would inflict on the complete process. This eventually eases the plasticization of the molds.

Another mistake that some plastic molding manufacturers might make is hosting the pressure at once. The trick is to introduce the pressure gradually so that the mold can get used to it along the way. This also ensures even distribution of injected molding throughout the mold.

This will enable the mold to adjust to the gradual pressure. Moreover, there should be the availability of a proper venting system so that when the system gets heated it can exhaust out the extra pressure.

Setting the Injection Molding Speed to Optimize to Control shrinkage and Mold in Stress

Speed is a variable that changes a lot and has to build up the whole procedure. It is highly likely that a slower speed can affect the molding machine and process damage. Therefore, when the injection molding speed is set to maximum, it performs at its optimum.

The high speed assures a lot of things. Firstly, it makes the plastic fluidity compatible with the molds. Next, it controls the shrinkage possible due to lack of speed indulgence. And lastly, the high-speed rate helps the process to vent out the building pressure at frequent intervals. This also helps in reducing the stress in the mold which might accumulate to an uneven mold build-up.

Conclusion

A plastic molding manufacturer should work around parameters that optimize the production of injection plastic molding. This is the only way they can control the optimized values of the building temperature plus machine and oil temperatures too. It is safe to say these steps will lead to adjusting pressure, controlling shrinkage, and minimizing mold in stress altogether.

For more information Contact US Today!

You May Also Read: Identifying the Plastic Molding For in Chain Process Parameters