The automotive industry has specifically found plastics to be useful in-vehicle components mainly because of their versatility and other significance. Also one of the widely used methods for integrating plastics with automotive engineering is precision molding. Automotive applications of precision mold for automotive parts are to make each and every part formed with superior accuracy, durability, and consistent quality. This has also transformed the manner automobile companies develop, construct, and integrate different components of a particular car model.

Precision Molds in the Production of Automobile Parts

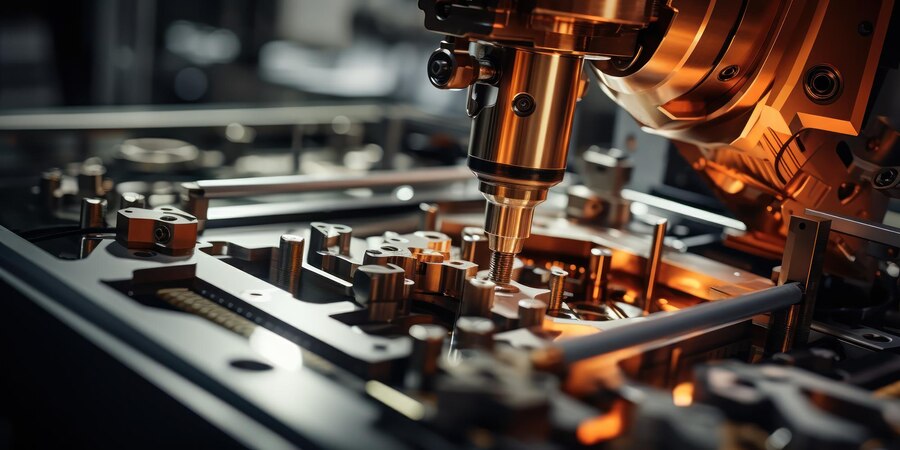

Precision molding undertakes the process of producing accurate molds that act to shape plastic and metals that are in the car. Auto spare parts manufactured with precision mold are vital in the aspect of performance, durability, and safety in automobiles. Precision molds have a wide usage in automobiles where automotive components like connectors, inner products, engines, and car bodies are produced.

For instance, automotive plastic injection connectors are nowadays an important element of electric systems in vehicles. These connectors are molded to fine tolerance and deliver high mechanical strength, good anti-corrosive characteristics, and long life. They are made to enable them to work well in the automotive environment such as with fluctuating temperatures and in contact with different chemicals.

Advantages of Precision Mold for Automobile Industry

Superior Material Properties

Another benefit realized from precision mold for automotive parts is the fact that the body of the molded parts offers improved characteristics. The plastic material common in injection molding possesses desirable attributes such as low density, high rigidity, low material cost, and ease of processing. These qualities make plastics suitable for many auto applications including structural, trim, and under bonnet sections.

Consistent Quality

In precision molding, it is possible to produce an auto part that has the same quality as the past auto part therefore reducing variability. The injection molding process is rigid, and the occurrence of flaws is seldom because the parts are produced to specific standards. Which must, for the automotive parts to be safe and reliable, have to be consistent? These precision molds make it certain that all engine components, trim parts, and any other part fashioned into a car will be of high quality to fit the automobile market.

Enhanced Design and Depth

In automotive parts, precision molds result in better design solutions. The injection molding process enables automobile manufacturers to obtain highly specialized part designs and intricate shapes, which would otherwise be out of the question or financially unfeasible to achieve through some other manufacturing methods. This makes for better performance and aesthetics in component manufacture due to the inherent feasibility of quite detailed part geometries.

Cost-Effective Production

Precision molds thereby assist in lowering expenses at the time of production to a great extent. That is because the injection molding process entails high efficiency in the production and it cuts across short time thus eliminating the cost of labor. Moreover, generating larger quantities of parts also reduces the cost per part because of its manufacturing in large volumes. There is also optimized resource use, wherein manufacturers get better use of the materials they incorporate in the finished product to avert losses and raise the general expense-efficiency conditions of product manufacturing.

Versatility

Depending on the type of molded part, automotive plastic injection molding can be entirely flexible. By using the process, it is quite possible to develop a variety of auto parts, and this can be interior and exterior auto parts as well. Maple has also acclaimed its expertise in precise molding solutions for sedan seatbacks, deckled trims, inside door handles, engine parts, roof parts, lighting systems, and many more. This means that automakers can gain specific attributes in design and functionality and ensure that every part is optimized for its application.

Examples of Automotive Parts Made through Precision Cast Molds

Precision molds are used to produce a variety of automotive components, such as:

- It includes seat back parts for comfort and safety.

- There are also deckled trims that give that professional finish to the edges.

- Inside door handles are easier to use and also which are long-lasting.

- Utility and luxury accentuation components that augment the door trim.

- Parts of the engine need to be fine in order to achieve the required efficiency.

- Roof components for load bearing and for appearance.

- Light bulbs of a style that has attained safety and visibility requirements.

- Fenders safeguard of car from flying particles and other unfavorable conditions.

- Bags that help to exercise forceful pull on the passengers to avoid harm.

- Climate control in electrical equipment parts for an air conditioner.

Why Choose ACE Group for Automotive Precision Molds?

ACE Group has been identified as a company with considerable experience in manufacturing of relatively precise molds for automotive applications. Here's why we are the preferred choice for your automotive needs:

Posted Experienced In-House Design and Development Team

We have worked on many projects for auto manufacturers to design or develop unique solutions for our customers. We also enjoy handling our clients from different parts of the world and it can ensure that all works are done under international standards.

OEM/ODM Services

Yes, we are OEM/ODM manufacturers which means we can make special customized products according to customers’ requirements. From complex part requirements to mass production, we will ensure that you receive high-quality services and assistance.

Strong Quality Control

At ACE Group our production processes are fairly well-equipped to meet the quality standards of automotive parts production. Quality and reliability are the key factors in choosing the inventory on offer to our customers.

Fast and Efficient Service

We are aware of the role of time. Our samples are always subjected to strict quality inspection so we guarantee that your parts are delivered on time without fail. Some of the benefits of our team involve proper coordination with clients in order to enhance their flow of communication.

Design Expertise

Our design specialization enables us to have the technical ability to provide its clients with accurate molds which details to the T as per the client’s order and requirement. Here working together ensures that we deliver the best results irrespective of the design complications.

Conclusion

Precision molds are an essential part of the automotive manufacturing process, offering superior quality, design flexibility, and cost-effective production. Whether you’re producing seatbacks, engine components, or electrical connectors, precision molding ensures that every part meets the high standards of the automotive industry. At ACE Group, we are committed to delivering high-quality automotive parts that enhance the performance, safety, and efficiency of your vehicles. For more information on our precision mold solutions for automotive parts, visit ACE.