Precision Mold Tooling: The Ambition of High-Quality Manufacturing

This article discusses the need for precision mold tooling in the current and future environment of manufacturing by focusing on industries such as medical, automotive, aerospace, and electronics industries. In light of the modern world's technological development and improved materials, high-precision mold tooling is a significant attribute of manufacturing. This paper aims to discuss the principles of precision mold tooling, categories of mold tooling processes, and their uses in different fields.

What does the Term Precision Mold Tooling Mean?

Precision mold tooling is the process of making molds with very high accuracy, for high tolerance parts. It covers the making of tools and tooling used in manufacturing procedures such as injection molding, blow molding, die casting, and others. The first and most important is to create parts that will fit into the necessary application perfectly, as they are to be incorporated into systems.

Mold tooling has to be precise, which is measured in microns the tools that are used are expected to be strong and made from steel aluminum, or High grade alloys. No matter if it is a job for one or two specific parts, or for thousands of pieces, precise mold tools guarantee the required quality.

The Importance of High-Precision Mold Tooling

High precision mold tooling holds a significant position in a number of industries. The quality of the mold defines the quality, sturdiness, and functionality of the artifact in question. For example, in the manufacturing of medical devices, various tolerances that indicate the degree of accuracy required of each component are critical because the deviation of a few micrometers may change the performance or even the safety of a device. In the same way, industries that manufacture auto and aerospace parts that work under heavy pressure require precision molding.

High precision leads to less mistake production, less wastage, and high efficiency in the mold tooling. It enables one to obtain high accuracy and precision of parts that are required in the making of assemblies that operate with precise dimensions and tolerances.

Key Concepts in Precision Mold Tooling

Precision Mold Design: The design process is a critical aspect of the mold tooling. It encompasses making drawings of the mold in the form of computer-aided designs commonly referred to as C.A.D. to generate models that detail how the mold will perform in the course of manufacturing. Accuracy in developing, detailed mold confers efficiency in its performance and durability, which negates regular maintenance or changes.

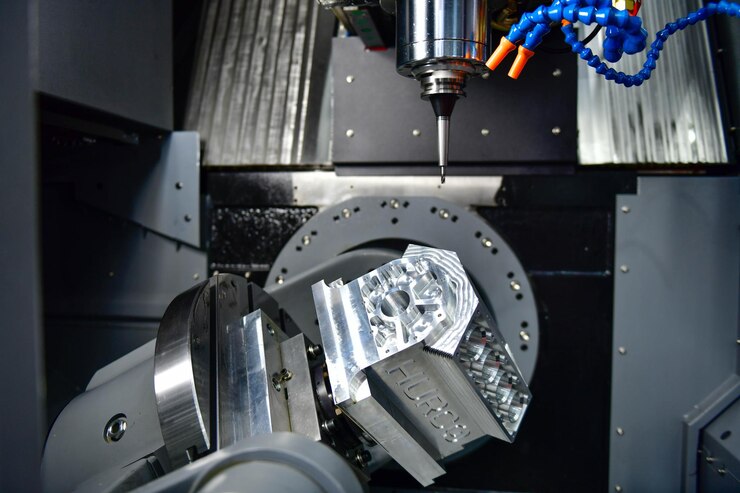

Precision Mold Manufacturing: This means the real construction of the mold—that is, the manufacture of not just the mold itself but also of the matrix in which it’s set. High precision is achieved by the use of modern methods in manufacturing tooling such as Computer Numerical Control machining, Electrical Discharge machining among others, Near Net Shape Manufacturing like 3D printing.

Precision Mold Engineering: Precision molding engineering relates to the detailed enhancement of the tool based on the requirements of the product to be manufactured. For example, engineers liaise with designers to ensure the quality and operation of the mold produced is highly efficient.

Mold Tooling Services: Some of the mold tooling services encompassing the creation of molds as well as their annihilation entails the design and fabrication of molds. Continued support for the molds is provided for the advantage of the manufacturers because this will see the molds function as expected throughout their lifetime expectancy.

Use Case Scenarios by Line of Business

Medical Mold Tooling

Health-related medical product assemblies need to be highly accurate so that the mold tools used for the manufacturing process are similarly precise. The tools have to accommodate delicate and frequently intricate shapes, and the material must be biocompatible and resistant to the sterilization process.

Automotive Mold Tooling

The manufacturing of parts in the automotive sector requires precision in mold tooling, especially in extenuating conditions. Tooling process should create part form; necessary features, that part will perform required functions, and be robust, as free as possible of defect.

Aerospace Mold Tooling

In aerospace mold tooling there is a lot of difference from other mold tooling simply because the parts created are important and need great attention to be given to them. Aerospace part mold tools need to go through very rigorous checks to ascertain the reliability of an aircraft.

Electronics Mold Tooling

Specialized molds for electronics have thin walls and very close dimensions to allow the interconnection of the components. Many industries require electronic manufacturing tools and the applications share commonalities of creating small intricate parts.

Packaging Mold Tooling

In packaging, accurate mold tooling is employed in the formation of uniform packaging evaporating, bottles as well as packaging material. High-precision molds are essential for minimizing waste of materials thereby producing goods of the required quality.

Services Provided By this Company

When sourcing for a mold tooling service provider it is important to find someone who will provide durable molds. Services offered by precision mold manufacturers typically include:

• Mold Design and Prototyping: To build and check the design specifications of the mold.

• Mold Fabrication: Utilizing better methods of machining to fashion the mold to the intended tolerance.

• Mold Repair and Maintenance: Sustentation and restoration services to increase the durability of the mold and enhance its efficiency.

• Mold Optimization: Optimization of the mold design and tooling for enhanced production to result in a decrease in the cost of production.

Conclusion

Precision mold tooling is a vital aspect of modern manufacturing, enabling industries such as medical, automotive, aerospace, and electronics to produce high-quality, reliable parts. Whether it’s through high-precision injection molds or blows molds, every step of the process requires attention to detail and advanced technology. By choosing the right materials and processes, manufacturers can achieve optimal results, minimizing waste and ensuring consistency across all production runs. For businesses in need of precision mold tooling solutions, partnering with an experienced manufacturer is key. Learn more about our mold tooling services at ACE to see how we can help with your next project.