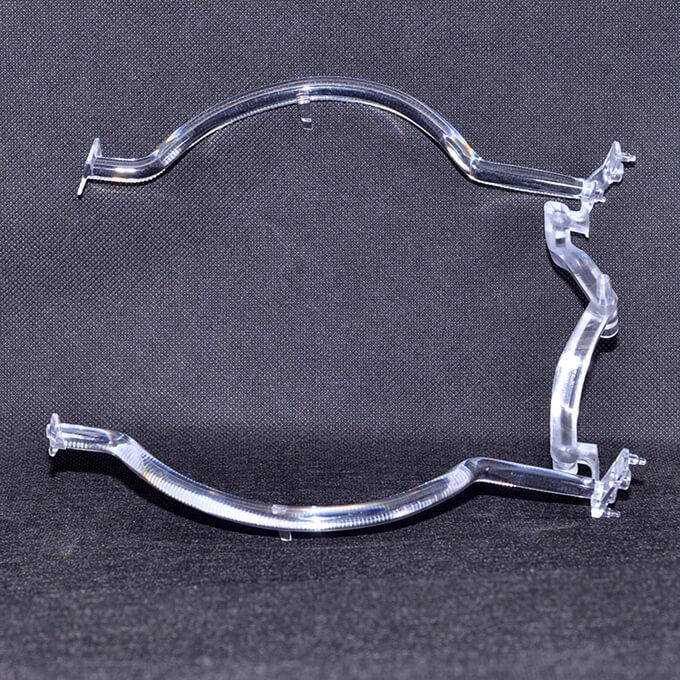

Automotive Lamp Injection Moulding

Automotive lamp injection moulding is a process that is used to produce parts for automotive lamps. This process is highly efficient and cost-effective, as it allows for the production of complex shapes and designs that would otherwise be difficult or impossible to make. It is widely used in the automotive industry for producing parts such as lighting components, instrument panels, bumpers, and body panels. ACE has been a key supplier to several well-known automotive OEMs. The infrastructure of comprehensive resources provided by ACE enables our clients to concentrate on what the automotive market values most—zero defects and reduced costs.

Benefits of Automotive Lamp Injection Moulding:

Automotive lamp injection moulding is a cost-effective and efficient way to produce automotive lamps. The process offers several advantages over traditional lamp manufacturing techniques, including increased precision, lower production costs, and improved product quality. Additionally, the use of advanced materials and technologies in automotive lamp injection moulding can help to reduce the environmental impact of the production process.

Versatility: Automotive lamp injection moulding is a process that helps create highly versatile automotive lamps. This process allows for the design and manufacture of different types of lamps, such as headlamps, taillights, and fog lamps, from a single tool. The process is highly efficient, with automation allowing for a fast production cycle and high-quality parts.

Cost efficiency: Automotive Lamp Injection Moulding is a cost effective way to produce automotive lamps. By utilizing automated machinery, the process is more efficient than traditional methods, resulting in lower labor costs, fewer errors and a faster production time.

Faster production: Automotive Lamp Injection Molding is a process that uses heated plastic to create complex shapes and components for the automotive industry. This process is faster and more efficient than traditional manufacturing, allowing companies to get products to market faster and with higher quality.

We can build the automotive parts as follows:

- Seat back

- Deckled trim

- Inside door handle

- Door trim

- Engine parts

- Roof parts

- Lighting parts

- Mudguard parts

- Airbags

- Air conditioner components

Why Choose ACE Group

1. We have an in-house design and development team that is highly experienced. We are at ease and skilled in dealing with international clients.

2. We offer OEM/ODM services to all customers and have professional customer support and project management teams available 24 hours a day, seven days a week.

3. We have put in place a strict quality control system to ensure that our products are of the highest quality and that we provide the best service at the lowest possible price.

4. High-quality inspection samples are always available and can be delivered to you quickly.

5. Design skills: create designs based on customer requirements.

6. We deliver goods on time and transparently work with customer.

| Brand Name | ACE |

| Model Number | ACE Mould |

| Surface Treatment | Texture / EDM / SPI Chrome Coating |

| Plastic Part Resin | Thermoplastic / Thermosetting |

| Multi Injection | Single / Double / Multi color |

| Design Software | UG, PRO/E, SOLIDWORKS, CAITA, CAD, STP, X_T, IGS, PRT, etc |

| Injection System | Cold runner / Hot runner |

| Part Size Range | Up to 1500mm |

| OEM/ODM | Acceptable |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |