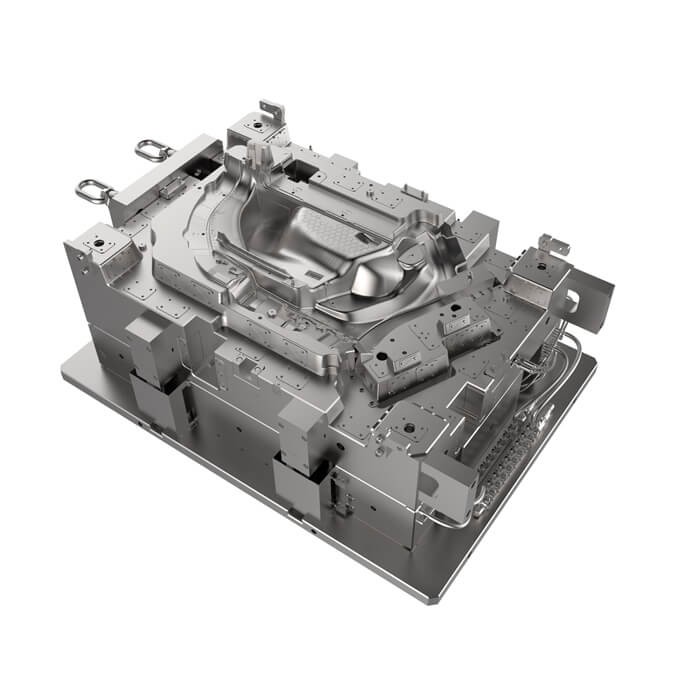

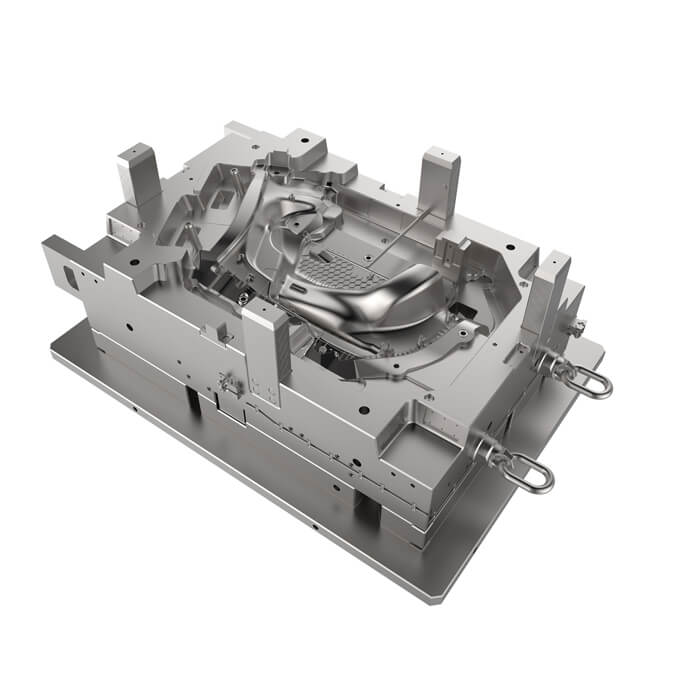

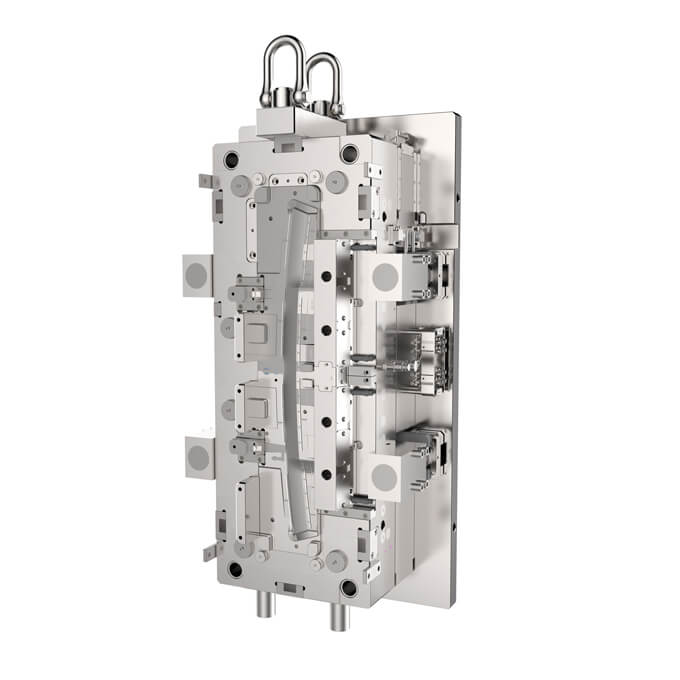

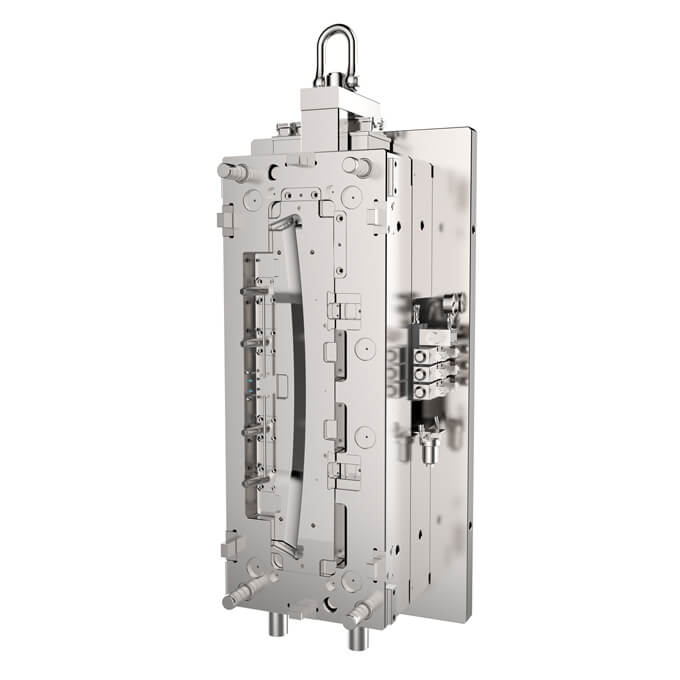

Automotive Plastic Injection Mould

Professional automotive plastic injection molding is a highly specialized process that requires both expertise and experience. It is essential to ensure that the automotive plastic injection molds are produced to the highest standards to ensure the safe and reliable operation of the vehicle. It is used to produce a wide variety of components such as interior and exterior trim, dashboards, bumpers, and much more. The process involves shaping molten plastic into the desired shape and then cooling it to a solid form.

Benefits of China Professional Automotive Plastic Injection Mould

Professional automotive plastic injection moulds are becoming increasingly popular due to their many advantages. It offers a range of benefits, including increased design flexibility, better dimensional accuracy, improved production cycle times, and lower production costs As the automotive industry continues to evolve and become more competitive, professional molds are becoming an essential part of the production process.

Faster production time: Automotive plastic injection moulds help reduce production times by streamlining the process of creating plastic parts for vehicles. This is done by reducing the number of steps required to create a part and utilizing automated processes such as robotic moulding to speed up the process.

Improved quality: The automotive industry is one of the most competitive industries on the planet. With new technologies and materials being developed all the time, the quality of the products produced must remain high. Automotive plastic injection mold is one of the most important tools in the automotive industry when it comes to improving the quality of products. By using a combination of different materials and processes, automotive plastic injection moulding can produce parts that are stronger, lighter, and more cost-effective than traditional manufacturing methods.

Cost savings: Automotive plastic injection moulding is a cost-effective way to produce parts for vehicles. This process can save you money because it is efficient and precise. It also uses less material than other processes and can produce parts with complex shapes. Additionally, a mold can be used multiple times, reducing the cost of production. The benefits of these cost savings include improved product quality, faster production, and reduced environmental impact.

We can build the automotive parts as follows:

- Seatback

- Deckled trim

- Inside door handle

- Door trim

- Engine parts

- Roof parts

- Lighting parts

- Mudguard parts

- Airbags

- Air conditioner components

Why Choose ACE Group

1. We have an in-house design and development team that is highly experienced. When dealing with international clients, we are at ease and knowledgeable.

2. We offer OEM/ODM services to all customers and have professional customer support and project management teams on call 24 hours a day, seven days a week.

3. We have put in place a rigorous quality control system to ensure that our products are of the highest quality and that we provide the best service at the lowest possible cost.

4. High-quality inspection samples are always available and can be delivered to you quickly.

5. Design expertise: Create designs according to client specifications.

6. We deliver goods on time and work openly and honestly with customers.

| Brand Name | ACE |

| Model Number | ACE00018 |

| Surface Requirement | Texture / EDM / SPI Chrome Coating |

| Plastic Part Resin | Thermoplastic / Thermosetting |

| Ejector System | Pin / Air Valve / Stripper plate |

| Injection System | Cold Runner / Hot Runner |

| Multi Injection | Single / Double / Multi Color |

| Process Servicing | Injection Moulding for automotive plastic injection parts |

| Standard Parts / Cylinders | DME / HASCO / PROGRESSIVE / MISUMI / Parker / HP / Merkle |

| OEM/ODM | Acceptable |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |