The components of an injection molding machine are crucial elements that determine the efficiency of the injection molding process and the quality of the final products. Injection molding machines are used to heat, melt, and inject plastic materials into molds, where they cool and form the desired parts. High-quality components ensure the stability of the production process and the consistency of the finished products.

Key Components

- Injection Unit

- Barrel and Screw: Responsible for heating, melting, and pushing plastic granules into the mold, ensuring uniform material flow and filling.

- Injection Seat: Supports and positions the barrel and screw, ensuring stability and precision during the injection process.

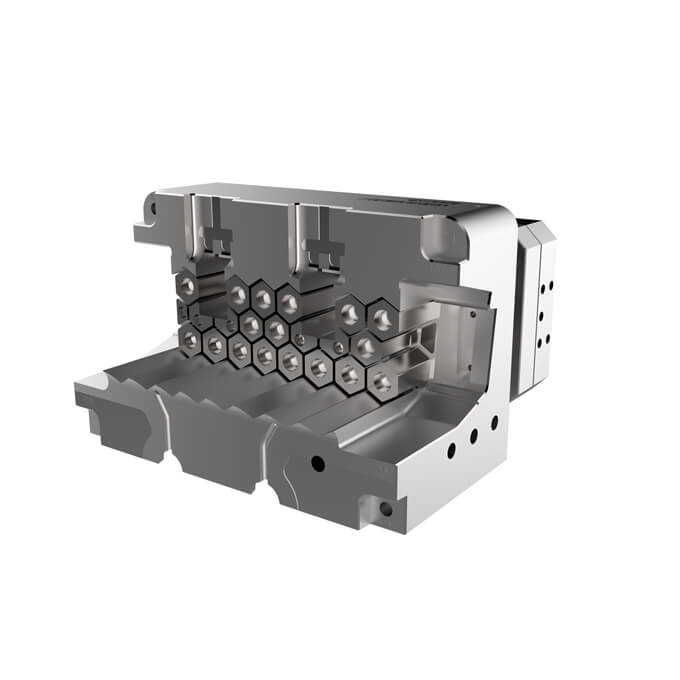

- Clamping Unit

- Movable and Fixed Platens: Fix and support the mold, ensuring it stays in the correct position during injection and cooling.

- Clamping Mechanism: Provides sufficient clamping force to prevent the mold from separating during injection, ensuring product quality.

- Hydraulic System

- Oil Pump and Hydraulic Cylinders: Provide power to control the movements of the injection and clamping units, ensuring coordinated operation of all components.

- Hydraulic Control Valves: Regulate the pressure and flow of the hydraulic system for precise motion control.

- Control System

- PLC Controller: Programs and controls the operational steps of the injection molding machine, offering precise parameter setting and monitoring functions.

- Display Panel: The human-machine interface allows operators to set and monitor the machine's operational status and parameters.

- Cooling System

- Cooling Water Pipes and Chillers: Used for cooling the mold and machine components, ensuring the plastic material cools and solidifies quickly during molding.

- Temperature Controllers: Regulate the temperature of the cooling water, keeping the mold and machine components within optimal temperature ranges.

- Drive System

- Motors and Reducers: Provide power to the moving parts of the injection molding machine, ensuring efficient operation and precise control.

- Transmission Mechanism: Transmits power to the injection and clamping units, achieving precise motion control.

Summary The high quality and precise design of injection molding machine components are key to ensuring the stability of the injection molding process and the quality of the products. Through continuous technological innovation and improvement, we are dedicated to providing customers with efficient and reliable injection molding machine components to meet the production needs of various plastic products.

| Brand Name | ACE |

| Model Number | ACE00029 |

| Material | ABS, PC, PEEK, ULTEM |

| Shaping Mode | Over Moulding, Insert Moulding |

| Mould Standard | DME or HASCO |

| Surface Treatment | Texture, Polishing, Coating, Painting |

| Surface Request | EDM or High Polish |

| Injection Moulding Process | Horizontal Injection |

| OEM/ODM | Acceptable |

| Certification | ISO9001:2015 |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |