We are leading suppliers of high precision plastic injection insert molding parts, dedicated to providing exceptional products and services. Our components excel in precision and durability, playing a crucial role in various applications. Below is a detailed description of our products:

1. High Precision Manufacturing

We use state-of-the-art injection molding technology and equipment to ensure each insert molding part achieves high precision. Our production process is strictly controlled, with tolerance levels reaching ±0.01mm, ensuring each part meets your design specifications.

2. Material Selection

We offer a variety of high-performance plastic materials, including but not limited to ABS, PC, PA, and POM. These materials have excellent mechanical properties and chemical resistance, performing stably in high-temperature environments. We can also recommend the most suitable material based on your specific needs.

3. Custom Design

We understand that each customer’s needs are unique, so we offer comprehensive customization services. Our engineering team works closely with you, from initial design to final production, to provide the best solution. We can handle complex geometries and structures to meet your specific application requirements.

4. Insert Molding Technology

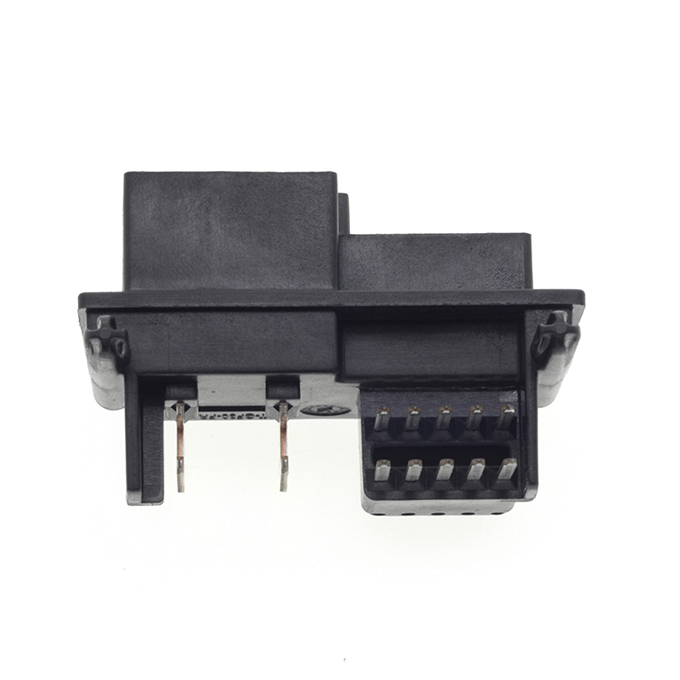

Our insert molding technology seamlessly combines metals, ceramics, or other materials with plastic parts, enhancing the overall performance and functionality of the parts. This process is especially suitable for applications requiring high strength and high conductivity, such as electronic components and automotive parts.

5. Application Fields

Our high precision plastic injection insert molding parts are widely used in various industries, including but not limited to automotive manufacturing, electronics, medical devices, aerospace, and consumer goods. No matter how complex your application is, we can provide you with reliable solutions.

6. Quality Assurance

We have a stringent quality control system, from raw material procurement to final product inspection, ensuring every product meets the highest standards. Our production facilities are certified with ISO 9001 and TS 16949, guaranteeing the quality and reliability of our products.

7. Customer Support

We are committed to providing excellent customer service. From design consultation and sample production to mass production, our professional team is always ready to offer support and advice, ensuring the smooth progress of your project.

| Brand Name | ACE |

| Model Number | ACE Mould |

| Mould Base | LKM, HASCO, DME, etc |

| Mould Material | NAK20, S136, P20, 718H, 738H, 45#, etc |

| Mould Cavity | Single or Multi |

| Tolerance | +/- 0.01mm |

| Data Exchange | UG, PRO/E, SOLIDWORKS, CAITA, CAD, STP, X_T, IGS, PRT |

| OEM/ODM | Acceptable |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |