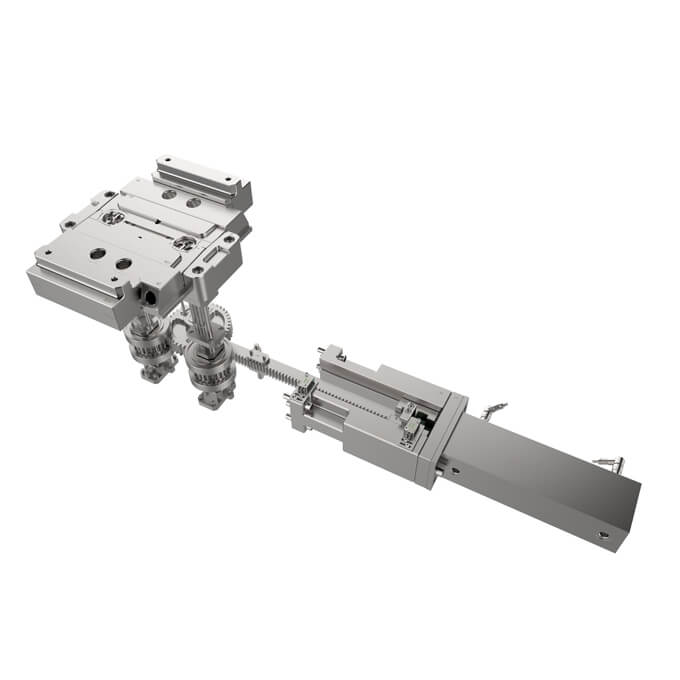

Mould Components

Mould components are an important part of the design of plastic products. They have the strength, accuracy, and stability required to produce high-quality products that meet the needs of customers. Mould components can be used to create complex shapes with intricate details, and they can be tailored to a wide range of applications. They are used as highly precise components for the manufacturing of automobile parts. In the manufacturing process, the components must be machined to precise specifications, often with a high degree of accuracy and repeatability.

ACE has been a key supplier to several well-known automotive OEMs. ACE's comprehensive resource infrastructure enables our clients to focus on what is most important in the automotive market: zero defects and lower overall costs.

Benefits of Mould Components for Your Business

Mould components are essential components for a variety of applications, from plastic injection moulding and die casting to metal forming and stamping. They provide a range of benefits, such as improved accuracy, repeatability, and cost savings, as well as enhanced product quality and performance.

Enhanced Durability: Mould components are an integral part of the manufacturing process, and their durability plays a major role in the success of a product. By using durable mould components, manufacturers can reduce production costs, improve product quality and extend the life of their products. Molded components have been used in many industries, such as automotive and aerospace, for decades. However, in recent years, their use has become increasingly popular due to their enhanced durability.

Improved Precision: Mould components are essential for manufacturing high-quality products with precise dimensions. Using advanced technologies, such as precision tooling and high-precision manufacturing processes, mould components can be created with improved accuracy and efficiency. This allows for greater versatility and faster production times, resulting in better products at lower costs.

Cost savings: Mould components are parts of the moulding process used in the production of plastic and other materials. By using mould components, manufacturers can save money and time by reducing the number of parts needed and cutting down on labor costs.

We can build the automotive parts as follows:

- Rear seat

- Decklid edging

- Inside doorknob

- Door casing

- Engine components

- Roof components

- Lighting components

- Mudguard components

- Bags of air

- Components of an air conditioner

Why Choose ACE Group

1. We have a highly experienced in-house design and development team. We are very comfortable and skilled in dealing with our international clients.

2. We provide OEM/ODM services to all types of customers and have professional customer support and project management teams on hand 24 hours a day, seven days a week.

3. We have a strict quality control system in place to ensure that our products are of the highest quality, that we provide the best service, and that our prices are competitive.

4. Quality inspection samples are always available and can be quickly delivered to you.

5. Design ability: create designs that adhere to customer specifications.

6. We deliver goods on time and work transparently with customers.

| Brand Name | ACE |

| Model Number | ACE00035 |

| Material | ABS, PC, PEEK, ULTEM |

| Shaping Mode | Plastic injection moulding |

| Mould Standard | DME or HASCO |

| Surface Treatment | Texture, Polishing, Coating, Painting |

| Surface Request | EDM or High Polish |

| Injection Moulding Process | Horizontal Injection |

| OEM/ODM | Acceptable |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |