Two Shot Injection Moulding

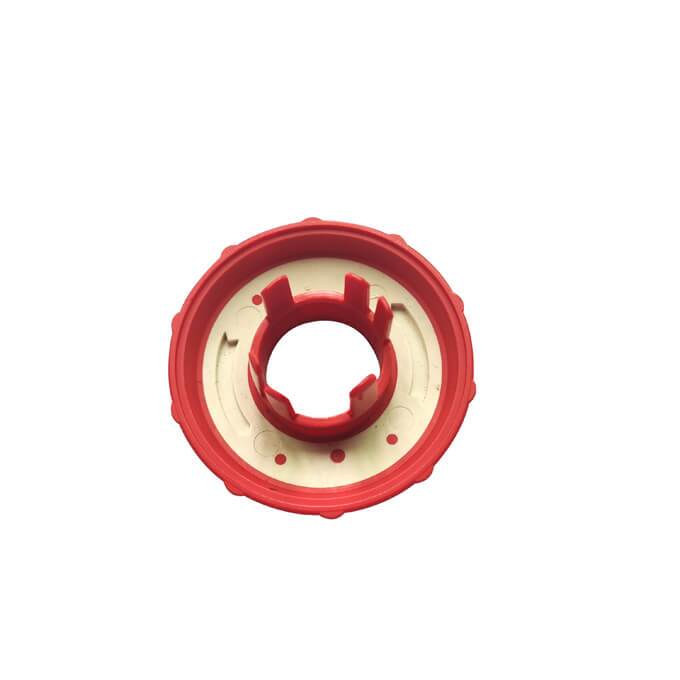

Multi-shot and two-shot plastic injection moulding are efficient and cost-effective methods for molding customized plastic parts with two or more plastic resins or colors in a single operation.

Plastic polymers from two or more injection units are applied through independent nozzles on a plastic injection moulding machine to produce custom plastic parts such as soft-grip insert parts, multi-color parts, dashboards or gauges, or parts with moulded seals, flexible hinges, or movable parts in multi-shot and two-shot custom plastic injection moulding.

You can achieve the required integrated functions on rigid parts, multiple colors and materials, moulded graphics, and soft-touch layers with multiple injections and two injections of plastic injection moulding, while reducing production steps, time, and costs.

Two Shot Mould Manufacturer

Our mould factory has a wide range of capabilities and processes to meet the technical requirements, volumes, and cost targets of each plastic injection moulded part, including Rotary Platen Two-Shot Mould, Core Toggle Two-Shot Mould, Index Plate Two-Shot Mould, Core Toggle Two-Shot Mould, Cavity sliding structure, and second injection units mounted on the 2K injection mould. To differentiate ourselves in the industry, we quickly manufacture high-quality moulds at reasonable prices.

Benefits of Two-Shot Injection Moulding

Two-shot injection moulding is a process that uses two different materials to create a single product. This process offers some benefits including cost savings, improved product performance, and waste reduction. It is a great way to take advantage of the different properties of multiple materials to create a product with greater strength, durability, and aesthetic appeal.

Increase product features: This technology has been used in a variety of industries including medical, aerospace, automotive, and home appliances. It allows for the manufacture of complex components with complex shapes and intricate details.

Enhances quality: This process is especially useful for creating complex parts with intricate features. The process can also be used to reduce production costs and improve efficiency.

We can build the automotive parts as follows:

- Seat back

- Deckled trim

- Inside door handle

- Door trim

- Engine parts

- Roof parts

- Lighting parts

- Mudguard parts

- Airbags

- Air conditioner components

Why Choose ACE Group

1. We have an in-house design and development team that is highly experienced. We are at ease and skilled in dealing with international clients.

2. We offer OEM/ODM services to all customers and have professional customer support and project management teams available 24 hours a day, seven days a week.

3. We have implemented a strict quality control system to ensure that our products are of the highest quality, that we provide the best service, and that our prices are competitive.

4. High-quality inspection samples are always available and can be delivered to you quickly.

5. Design ability: create designs that meet customer requirements.

6. We deliver goods on time and transparently work with customers.

| Brand Name | ACE |

| Model Number | ACE Mould |

| Shaping Mode | Plastic injection mould |

| Mould Cavity | Single or Multi |

| Design Software | UG, PROE, CAD, CAXA, etc |

| Surface Treatment | Polish, texture, sandblasting, etc |

| Mould Material | P20 / 718 / 738 / NAK80 / S136 |

| OEM/ODM | Acceptable |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |