Plastic Injection Mold Making; Tools and Steps of Construction

Plastic injection mold making is a very meticulous process. Perhaps, this is why a simple single cavity plastic injection mold can cost up to $5000. The entire mold manufacturing process involves cutting-edge tools, ultra-modern technology, and the mold makers' ultimate craftsmanship.

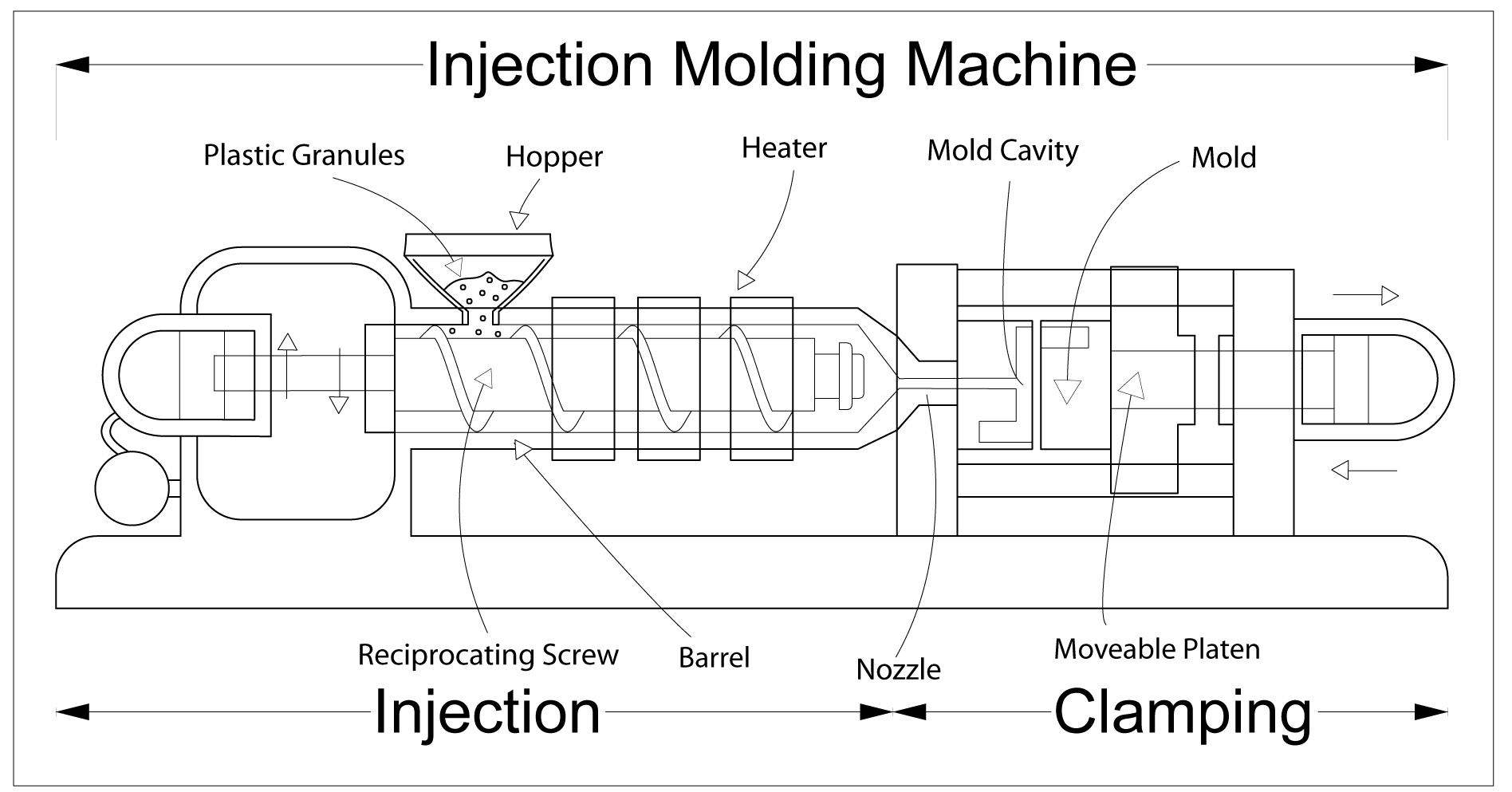

The plastic injection molding process is a high-volume plastic piece manufacturing process. This process fundamentally utilizes a plastic injection mold and molten plastic to form plastic pieces of the desired shape and size.

First, the mold makers melt the plastic that may initially be present in the form of beads. They then feed the molten plastic into the injection molding machine, injecting the liquid polymer into the mold's cavity.

The plastic injection molds have pathways to allow the coolants to circulate the hot plastic in the cavity to cool it quickly and increase its solidification rate.

You May Also Read: Plastic Injection Molding Service – Know Everything about it

The mold opens, and ejector pins now push the cooled and solidified plastic piece out of the cavity. Then the mold closes back, and the machine injects more liquified plastic to make the next piece. The production of one piece (or multiple pieces if the mold has multiple cavities) completes one injection molding cycle.

Each cycle of injection molding may take only a few seconds to complete. In this way, the plastic injection molding process can produce millions of small and large plastic pieces in a comparatively short time frame.

What is A Plastic Injection Mold?

As their name suggests, plastic injection molds are an essential part of the plastic injection molding machines. They can be made in any shape and size and can accommodate multiple cavities to increase the number of pieces made per cycle. Even the cheapest molds are capable of producing hundreds of thousands of plastic components in their lifetime.

A plastic injection mold is a metallic (mostly steel or aluminum) cube hollow from inside. It has pathways to allow for molten plastic to get from the injection point to the mold cavity. These pathways are called 'runners.' It also has holes for coolant (usually water) circulation and cools and solidifies the plastic.

There are two significant parts of a mold, which most mold makers refer to as Plate A or the cavity side and plate B or the core side. Plates A and B further comprise multiple smaller parts. Plate A is immobile and carries the runners and the gates, which are the entry point of molten plastic into the cavity. The cavity is also present on Plate A.

Plate B or the core side is mostly only responsible for opening and closing the mold and carries ejector pins mounted on a core plate that pushes the plastic piece out.

Tools Used in Making Plastic Injection Mold

Plastic injection mold making is a process with zero tolerance for any mistakes. Thus it employs high precision and perfect finish tools for the manufacture of every single plastic mold.

Firstly, plastic injection mold making uses a milling machine that marks points on the steel, Aluminium, or any other material used for the mold for coolant circulation and screw holes.

The next tool used in this process is the drilling machine—the drilling machine drills through holes for coolant circulation in the mold and appropriate screw holes.

A Computer Numerical Control or CNC machine is a computer-controlled machine that cuts the metal piece into the desired shape and size. The cutting tool and the bench on which the metal piece sits in a CNC machine are computer-controlled. Thus, the CNC machine eliminates human operators' needs, and decreases lead time and labor cost.

An Electrical Discharge Machining Equipment makes intricate incisions and perform precise cutting on the metal piece. An EDM process utilizes electrical discharge and a liquid present between the metal electrode and the metal piece. The liquid acts as a conductor and conducts electrical current after coming in contact with the electrode. It generates a spark that makes a precise cut on the metal piece.

The plastic injection mold making also involves other miscellaneous tools such as hammers, mallets, and aluminum bars for beating the metal piece. It also employs sandpapers and ultrasonic instruments to scrap any marks left behind by EDM and CNC processes and ensure a perfect finish in the metal piece.

Construction Method

Step 1: Designing and Prototyping

The customers send their required product specifications to the mold makers. The mold makers assess these specifications and generate a mold prototype using mold making software.

After the customers approve the prototype, the mold makers simulate the entire molding process using the mold prototype they made earlier to determine plastics' flow characteristics and see potential defects and eliminate them.

Since the mold making process is very articulate and expensive, no final products are tolerable. Hence, this step is crucial because it eliminates the chances of errors in the final product.

Step 2: Procurement of Material

After the mold makers and customers are satisfied with the mold's designs and prototype, the mold makers order materials for making the mold. Two primary constraints determine the choice of metal- the customer's budget and molds durability.

Hardened steel makes molds that have a long life and are very durable. But with long life comes an increased price, and using steel for mold making increases the material procurement cost significantly.

The alternative to steel can be Aluminium. However, Aluminium is not as durable as steel, and an aluminum mold may wear out sooner than its steel counterpart.

Step 3: The Machining

After the mold's software designing is complete, the designers share their designs with the mold-making project manager. The project manager and his team of CNC and EDM programmers and machinists then set to work their magic on the metal piece.

The metal piece is first to cut into the desired shape using a CNC machine. The milling machine marks points for coolant circulation and screw holes. After this, a drilling machine drills holes for coolant circulation pathways and screw holes in handy during assembling.

After the mold makers have cut and drilled the metal piece, it goes ahead to the EDM process. The EDM process precisely cuts and shapes all the narrow and intricate pathways like runners and gates with high accuracy. EDM is capable of making precise incisions that CNC machining usually can't.

Finally, after having undergone the EDM process, the metal piece may need to undergo some bench work. Benchwork involves scraping the metal piece using tools like sandpaper or ultrasonic tools for an excellent finish.

Step 4: Inspection

After the metal piece's complete machining, the mold makers inspect to ensure proper contact between plates A and B. Once satisfied that both the components fit well, mold makers send the mold and its parts ahead for the next step.

Step 5: Assembly

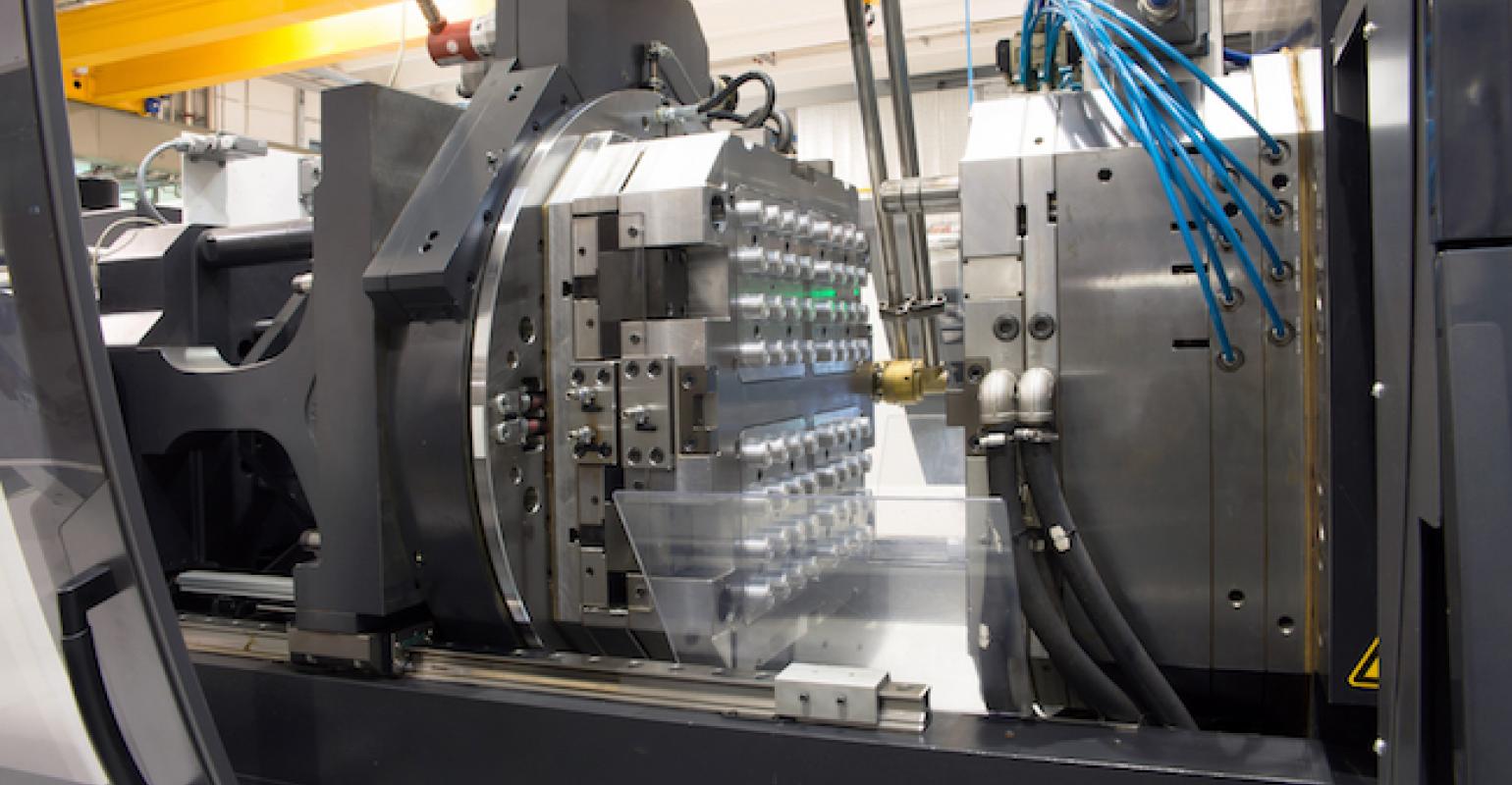

After passing through a detailed inspection comes the assembling of all the molds' parts, and then the mold is completed. Now the mold is ready to be placed inside a plastic injection molding machine and serve its purpose.

Step 6: Testing

Testing is the final step in the plastic injection mold making process. The newly assembled molds take their place in an injection molding machine. Machine operators feed customer-specified product parameters into the machine to see if the mold makes the product just the way the customer wanted.

After passing through the testing phase, the mold is ready to be sent to the customers.

You May Also Read: OEM Plastic Molding – How this Industry Can Grow Faster

Conclusion

Based on their simplicity (or complexity), plastic molds can take anywhere between a couple of weeks to a couple of months to complete. There are several stages of mold making. From designing the mold down to the final tryout, the mold makers have to ensure perfection in every step as there is no margin for mistakes in a plastic mold making process.

We offer high-quality Molding Making Services. To learn more, Contact Us Today.