Precision Mold Solutions: Our Team Builds Perfect Manufacturing Technology

Manufacturing requires the most exact possible results. Product performance and dependability reach their maximum levels when you use precision mold solutions to make medical devices automotive parts or electronic components. This article explains how precision molding helps multiple industries and shows its key uses and essential role in manufacturing today.

What Services Does Precision Mold Provide?

Our business uses special molds that produce exact dimensions and part characteristics with high precision. Specialized molding machines produced by advanced methods give us exact parts that match their required dimensional specifications. For plastic metal and composite materials molding needs exact control during production.

Special molds through custom molding and injection molding create products for various industry sectors, especially automotive aerospace medical, and electronics manufacturing. Plastic parts production sectors use their fundamental structure to deliver high-precision parts while maintaining strict dimensional requirements.

Why Do We Need Molds that Maintain Exact Measurements?

Mold precision helps manufacturers create parts with exact dimensions that deliver better product looks plus performance benefits. Any minor variations in aerospace and medical industries can produce dangerous results. Thus, molds with exact tolerances ensure the following benefits:

Superior Mold Quality: A highly accurate mold produces parts that both operate better and display improved quality.

Reduced Production Costs: When manufacturers use precision molds they save materials and speed up operations which results in notable cost savings.

Increased Product Lifespan: Products produced through precision molds endure longer because the mold makes the materials more resilient and maintains process consistency.

Improved Product Performance: Parts produced exactly to require specifications deliver performance enhancements most noticeable in important medical and automotive applications.

Our Production Method Explained

The process behind precision mold solutions typically involves the following steps:

Mold Design & Manufacturing

Companies begin precision mold creation by designing the mold. The early phase requires developing digital models including all performance standard requirements. Mold design professionals make essential changes to the mold design before manufacturing begins. Mold flow analysis helps us predict how different materials flow into the mold design during pressure testing.

Injection Molding

When both mold designs are ready injection molding starts up. Under high pressure liquid material is pumped into specific mold cavities. The mold set material aligns with its shape to create an exact finished part. Plastic injection molding creates large numbers of finished parts for car producers electronics manufacturers and healthcare device makers.

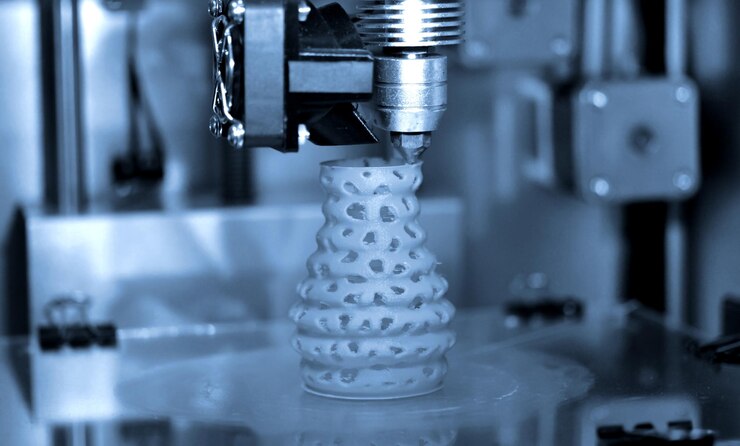

Design a Mold Made for Testing Without Using Patterns

Companies make test mold versions to check their manufacturing quality before beginning regular production. The tasks are completed through 3D printing for quick model development. Our development of prototype models helps us identify errors in design quickly which enables us to make necessary changes before production delays occur.

Mold Repair & Maintenance

Manufactured molds need upkeep and service to keep them working with precise results. Close inspection helps identify mold damage to fix it while replacing worn parts keeps the mold working correctly.

Benefits of Precision Mold Solutions

Our precision mold methods deliver strong benefits to customers. When precision molding assists industries that need dependable high-quality parts it becomes their essential solution. Some key benefits include:

Accuracy: Critical aerospace and medical products benefit from precision molds that produce parts exactly per project requirements.

Cost Efficiency: Though precision molds cost more initially they save money over time because they cut manufacturing expenses through less waste and better production methods.

Speed: Using precise molds helps our team produce parts quickly and exactly on schedule.

Flexibility: Manufacturers can make different shaped and sized parts through precision molding which lets them serve multiple applications.

Why Choose Precision Mold Solutions?

Businesses gain many advantages when they work with a precision mold solutions provider. When you partner with a mold design expert they will create products that exceed industry quality requirements during mold prototyping and injection molding stages. We deliver precise mold products to medical, automotive, electronics, and aerospace businesses through our specialized services. Through advanced technology and long-term expertise, our engineering team builds molds that meet high-performance standards and remain durable for lengthier periods.

Key Takeaways

- Organizations depend on precise mold-making techniques to produce quality parts for all business sectors.

- The mold-making process improves mold quality while improving finished product results while saving money.

- Aerospace medicine electronics rely completely on high-precision molding close tolerance molding and micro molding to function.

- Injection molding combined with mold prototyping helps us maintain production standards while delivering top results.

- Working with a suitable precision mold manufacturer benefits your product both in performance and saves you money over time.

Why Choose ACE?

We have a fast response rate. Our team provides fast email responses and sends quotations to clients the day they submit their requests.

- Our company employs designers and developers right on staff.

- Our quality assurance procedure maintains top-quality standards for all our products.

- Our product rates beat other company prices.

- Every manufactured sample leaves our facility immediately while quality testing shows all product specifications.

- We develop original equipment manufacturing and original design manufacturing services for a wide variety of clients.

- Our team guarantees products reach customers on schedule alongside dedicated shipping support.

- We show pleased satisfaction with our continuous partnership exceeding 96% of all our initial customers.

Conclusion

The role of precision mold solutions in modern manufacturing cannot be overstated. With our ability to produce high-quality parts that meet exacting standards, they are indispensable to industries ranging from aerospace to consumer goods. Whether you’re looking for custom molding, injection molding, or mold design services, precision mold solutions offer unparalleled accuracy, efficiency, and flexibility. By investing in precision molds, you ensure the creation of reliable, high-performing products that meet the needs of today's fast-paced manufacturing world. Our advanced molding systems and deep knowledge let us help customers overcome their toughest production issues. Contact today now!